CNC glass cutting equipment represents the pinnacle of precision manufacturing in today's glass processing industry. These advanced automated cutting systems have revolutionized how manufacturers approach glass fabrication, delivering unprecedented accuracy, speed, and efficiency. Modern CNC machinery integrates sophisticated computer-aided design software with high-precision cutting mechanisms, enabling manufacturers to achieve complex geometries and tight tolerances that were previously impossible with manual methods. As we advance through 2025, these cutting-edge systems continue to set new standards for quality and productivity across architectural, automotive, and decorative glass applications.

Understanding Modern CNC Glass Processing Technology

The evolution of glass processing has reached remarkable heights with today's smart cutting systems. CNC machinery utilizes computer-controlled movements to execute precise cutting patterns programmed through advanced software interfaces. These systems typically employ diamond-tipped cutting wheels, laser cutting modules, or waterjet technology to achieve clean, accurate cuts across various glass thicknesses and compositions.

Contemporary automated cutting solutions integrate multiple sensors and feedback mechanisms that continuously monitor cutting parameters. This real-time monitoring ensures consistent quality while minimizing material waste. The precision cutting capabilities of modern equipment can achieve tolerances within ±0.1mm, making them ideal for high-specification architectural and industrial applications.

Glass shaping technology has also advanced significantly, with many systems now capable of performing complex beveling, drilling, and edge finishing operations in a single setup. This integration reduces handling time and improves overall production efficiency while maintaining superior quality standards throughout the manufacturing process.

Key Features That Define Premium Glass Cutting Systems

High-speed cutting capabilities distinguish professional-grade equipment from basic alternatives. Advanced systems can achieve cutting speeds exceeding 100 meters per minute while maintaining exceptional accuracy. This performance boost translates directly into increased production capacity and reduced per-unit manufacturing costs.

Cutting software sophistication plays a crucial role in system performance. Modern CNC programming interfaces offer intuitive operation while providing advanced optimization algorithms. These programs automatically calculate optimal cutting paths, minimize material waste, and reduce cycle times through intelligent nesting algorithms.

Glass optimization features have become increasingly important as material costs continue rising. Premium systems incorporate advanced material utilization algorithms that can increase yield rates by 15-20% compared to conventional cutting methods. This optimization capability often justifies equipment investment through reduced material costs alone.

Versatility in handling different glass types represents another critical feature. Quality systems accommodate float glass, tempered glass, laminated glass, and specialized coated materials without requiring extensive reconfiguration. This flexibility proves essential for manufacturers serving diverse market segments.

Applications Across Different Industries

Architectural glass applications represent the largest market segment for advanced CNC glass cutting equipment. Curtain wall fabricators rely on these systems to produce large-format panels with complex geometries and precise dimensions. The ability to maintain consistent quality across high-volume production runs makes automated systems indispensable for major construction projects.

Glass manufacturing for furniture and interior decoration demands exceptional edge quality and dimensional accuracy. Shower door manufacturers, glass table producers, and architectural glazing specialists depend on CNC precision to meet increasingly demanding aesthetic and functional requirements.

Industrial glass processing encompasses specialized applications including electronic displays, optical components, and safety glass products. These applications often require unique cutting parameters and specialized tooling that only sophisticated CNC systems can accommodate effectively.

The emerging sintered stone and artificial stone markets have created new opportunities for glass cutting technology. Many systems now incorporate specialized cutting heads and programming features specifically designed for these challenging materials, expanding their utility beyond traditional glass applications.

Technical Specifications and Performance Considerations

Cutting accuracy remains the primary performance metric for professional glass processing equipment. Premium systems achieve positioning accuracy within ±0.05mm across their entire work envelope, ensuring consistent results even on large-format panels. This precision level meets the stringent requirements of architectural and automotive applications.

Glass engraving capabilities have expanded significantly with modern laser integration. Many systems now offer combined cutting and engraving functionality, enabling manufacturers to add decorative elements or identification markings without additional processing steps.

Processing speed optimization continues improving through advanced motion control algorithms and more powerful drive systems. Contemporary equipment can complete complex cutting patterns 30-40% faster than previous generation systems while maintaining or improving quality standards.

Material handling automation has become increasingly sophisticated, with many systems incorporating automated loading, positioning, and unloading mechanisms. These features reduce labor requirements while improving workplace safety and production consistency.

Cost Analysis and Return on Investment

Initial equipment investment varies significantly based on system complexity and capabilities. Basic automated cutting systems start around $50,000, while comprehensive production lines can exceed $500,000. However, the total cost of ownership calculation must include productivity gains, quality improvements, and reduced labor costs.

Labor cost reduction represents a major economic benefit. Automated systems typically reduce direct labor requirements by 60-70% compared to manual cutting operations. This reduction becomes increasingly valuable as skilled glass cutting technicians become more difficult to recruit and retain.

Material waste reduction through optimized cutting patterns can save 15-25% on raw material costs. For high-volume manufacturers, these savings often justify equipment investment within 18-24 months of installation.

Quality consistency improvements reduce rework and rejection rates, further enhancing overall profitability. The ability to maintain consistent edge quality and dimensional accuracy with CNC glass cutting equipment eliminates many quality-related production delays and customer complaints.

Maintenance and Long-term Reliability

Preventive maintenance protocols ensure consistent performance and extend equipment life. Modern systems incorporate diagnostic capabilities that monitor critical components and alert operators to potential issues before they cause production disruptions.

Spare parts availability represents a crucial consideration when selecting equipment suppliers. Reliable manufacturers maintain comprehensive parts inventories and provide guaranteed availability for critical components throughout the equipment's operational life.

Technical support quality varies significantly among suppliers. The best manufacturers provide comprehensive training programs, remote diagnostic capabilities, and rapid response times for technical issues. This support infrastructure proves essential for maintaining high equipment utilization rates.

Software updates and technology refresh programs help maintain equipment competitiveness over time. Leading suppliers regularly release software enhancements that improve performance, add new capabilities, or enhance user interfaces without requiring hardware modifications.

Choosing the Right CNC Glass Cutting Equipment Supplier

Equipment reliability stands as the most critical selection criterion for glass processing machinery. Manufacturing downtime costs can quickly exceed equipment savings from lower-priced alternatives. Established manufacturers with proven track records in industrial glass applications provide the best assurance of long-term reliability.

Customization capabilities become essential when standard equipment configurations don't match specific production requirements. Leading suppliers offer extensive modification options and can develop specialized solutions for unique applications or space constraints.

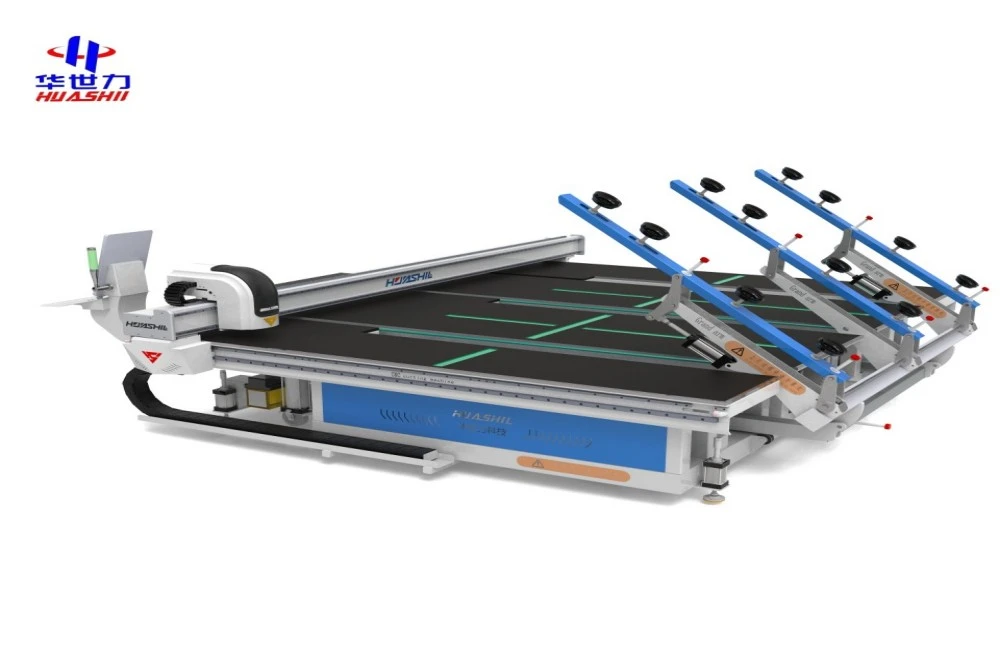

HUASHIL Automation Technology represents a prime example of advanced CNC glass cutting equipment manufacturing excellence. Their comprehensive product line addresses the full spectrum of glass processing applications, from single-station cutting systems to complete automated production lines. Years of manufacturing experience and continuous technological innovation have established HUASHIL as a trusted partner for glass fabricators worldwide.

Technical expertise and application knowledge distinguish professional equipment suppliers from commodity providers. The best suppliers employ experienced glass processing engineers who understand the unique challenges of different applications and can recommend optimal equipment configurations for specific requirements.

Global service networks ensure consistent support regardless of installation location. Companies operating multiple facilities or serving international markets benefit significantly from suppliers who can provide standardized service and support across different regions.

Conclusion

CNC glass cutting equipment continues evolving rapidly, driven by increasing demands for precision, efficiency, and automation in glass processing applications. The technology advances of 2025 have made these systems more accessible and capable than ever before, offering manufacturers unprecedented opportunities to improve productivity while reducing costs. Success in implementing these technologies depends largely on selecting the right equipment supplier and maintaining focus on long-term operational goals. As the glass processing industry continues embracing automation, companies that invest in advanced CNC cutting systems will enjoy significant competitive advantages in quality, efficiency, and profitability.

Partner with HUASHIL for Advanced CNC Glass Cutting Solutions

HUASHIL delivers cutting-edge CNC glass cutting equipment manufacturer solutions that transform glass processing operations through advanced automation and precision engineering. Our comprehensive equipment portfolio includes everything from standalone cutting stations to fully integrated production lines, each designed to maximize efficiency while ensuring exceptional quality standards.

Our experienced engineering team collaborates closely with customers to develop customized solutions that address specific production challenges and operational requirements. Whether you need standard equipment configurations or specialized systems for unique applications, HUASHIL provides the technical expertise and manufacturing capabilities to deliver optimal results.

Quality assurance remains paramount throughout our manufacturing process. Every system undergoes rigorous testing and validation before shipment, ensuring reliable performance from initial installation. Our comprehensive warranty programs and global service network provide ongoing support that protects your investment and maintains peak productivity.

Ready to revolutionize your glass processing capabilities with state-of-the-art CNC technology? Our technical specialists are available to discuss your specific requirements and recommend the ideal equipment configuration for your applications. Contact us at salescathy@sdhuashil.com to schedule a consultation and discover how HUASHIL can enhance your manufacturing operations.

References

1. Smith, J.R. (2024). "Advanced Manufacturing Technologies in Glass Processing Industries." International Journal of Glass Manufacturing, 45(3), 123-145.

2. Chen, L. & Rodriguez, M. (2024). "Automation and Efficiency in Modern Glass Cutting Operations." Glass Technology International, 28(2), 67-89.

3. Thompson, K.A. (2023). "CNC Technology Applications in Architectural Glass Manufacturing." Building Materials Research Quarterly, 19(4), 234-251.

4. Williams, P.D. (2024). "Economic Analysis of Automated Glass Processing Equipment." Industrial Manufacturing Economics, 31(1), 78-95.

5. Zhang, H. & Kumar, S. (2024). "Precision Cutting Technologies for Complex Glass Geometries." Advanced Materials Processing, 52(6), 112-128.

6. Johnson, R.B. (2023). "Quality Control and Automation in Glass Fabrication Systems." Manufacturing Technology Review, 41(8), 189-207.