Emerging technologies in compact glass cutting

The landscape of glass cutting is evolving rapidly, with innovative technologies paving the way for more efficient and precise cutting processes. Small glass cutting machines are at the forefront of this revolution, incorporating cutting-edge features that enhance their performance and expand their applications.

One of the most significant advancements is the integration of laser technology. Laser-guided cutting systems have dramatically improved the accuracy of cuts, allowing for intricate designs and patterns that were once impossible with traditional methods. These systems use a low-power laser to create a precise scoring line, which is then followed by a break wheel to complete the cut. This combination of technologies results in cleaner edges and reduced waste.

Another emerging technology is the use of computer numerical control (CNC) in small glass cutting machines. CNC integration allows for automated cutting processes, significantly reducing human error and increasing production speeds. Operators can input complex designs directly into the machine, which then executes the cuts with exceptional precision. This level of automation is particularly valuable for businesses that require high-volume production of custom glass pieces.

Advancements in cutting wheel materials have also contributed to the improved performance of compact glass cutters. New alloys and coatings have extended the lifespan of cutting wheels while maintaining their sharpness, resulting in more consistent cuts over time. Some machines now feature self-sharpening wheels, further reducing maintenance requirements and downtime.

The incorporation of IoT (Internet of Things) technology is another game-changer for small glass cutting equipment. Connected machines can now transmit real-time data on performance, maintenance needs, and production metrics. This allows for predictive maintenance, optimized workflow planning, and remote monitoring of cutting operations, enhancing overall efficiency and reducing costly downtime.

Augmented reality (AR) is making its way into the glass cutting industry as well. Some advanced small glass cutting machines now offer AR overlays that guide operators through the cutting process or provide visual representations of the final product before cutting begins. This technology not only improves accuracy but also serves as a valuable training tool for new operators.

The miniaturization of components has allowed for the development of truly portable glass cutters. These ultra-compact devices can be easily transported to job sites, opening up new possibilities for on-site custom cutting and repairs. This mobility is particularly valuable in the automotive and construction industries, where on-the-spot glass modifications are often necessary.

Sustainability and waste reduction with small cutters

As environmental concerns continue to shape industry practices, small glass cutting machines are playing a crucial role in promoting sustainability and reducing waste in glass processing. The compact nature of these machines contributes to their eco-friendly profile in several ways.

Firstly, the precision offered by advanced small cutters significantly reduces material waste. By achieving tighter tolerances and more accurate cuts, these machines minimize the amount of scrap glass produced during the cutting process. This not only conserves raw materials but also reduces the energy required for recycling excess glass.

Many modern compact cutters are designed with energy efficiency in mind. Their smaller size and optimized cutting mechanisms require less power to operate compared to their larger counterparts. Some models even incorporate energy recovery systems, capturing and reusing heat generated during the cutting process to further reduce overall energy consumption.

The durability and longevity of contemporary small glass cutting machines also contribute to their sustainability. Built with high-quality materials and featuring modular designs, these machines are easier to maintain and repair, extending their operational lifespan. This reduces the frequency of replacements and the associated environmental impact of manufacturing new equipment.

Water conservation is another area where small cutters excel. Many compact models use minimal or no water in their cutting processes, in contrast to some larger water jet cutting systems. This not only reduces water consumption but also eliminates the need for water treatment and disposal, further lowering the environmental footprint of glass cutting operations.

The ability of small cutters to process recycled glass effectively is an important factor in closed-loop manufacturing processes. These machines can handle the variations in thickness and composition often found in recycled glass, enabling manufacturers to incorporate more recycled content into their products without sacrificing quality or precision.

Furthermore, the compact size of these machines allows for more efficient use of factory space. This can lead to smaller, more energy-efficient facilities, reducing the overall environmental impact of glass processing operations. The reduced footprint also means less energy is required for climate control and lighting in production areas.

Some cutting-edge small glass cutting machines are now incorporating AI-driven optimization algorithms. These systems analyze cutting patterns to maximize material utilization, further reducing waste. By continuously learning and adapting, these smart cutters can suggest the most efficient cutting layouts for complex projects, ensuring that every piece of glass is used to its fullest potential.

Predicted trends: Where small glass cutters are heading

The trajectory of small glass cutting machine technology points to an exciting future filled with innovations that will further transform the glass industry. As we look ahead, several trends are emerging that will likely shape the next generation of compact glass cutters.

One of the most promising developments is the integration of artificial intelligence and machine learning capabilities. Future small cutters are expected to become increasingly autonomous, capable of self-optimization and real-time decision-making. These smart machines will be able to adjust cutting parameters on the fly based on material variations, environmental conditions, and production goals, ensuring optimal results with minimal human intervention.

Nanotechnology is set to play a significant role in the evolution of glass cutting. Research is underway to develop nano-engineered cutting surfaces that can achieve even finer precision and smoother edges. These advanced materials could potentially eliminate the need for secondary finishing processes, streamlining production and improving overall glass quality.

The trend towards multi-functionality is likely to accelerate. Future small glass cutting machines may incorporate additional processing capabilities such as drilling, polishing, and even surface treatments. This all-in-one approach would reduce the need for multiple machines, saving space and improving workflow efficiency in glass fabrication facilities.

Advancements in battery technology and power management systems are expected to lead to truly cordless, high-performance glass cutters. These portable units will offer unprecedented flexibility for on-site work, particularly in the construction and renovation sectors. Imagine being able to cut and shape custom glass pieces directly at a building site with the same precision as a factory-based machine.

Virtual and augmented reality integration is likely to become more sophisticated and widespread. Future glass cutters may feature holographic displays that project cutting lines directly onto the glass surface, or VR systems that allow operators to simulate complex cuts before executing them in the real world. This technology will not only improve accuracy but also enhance safety by allowing operators to visualize and plan cuts without physical risk.

The push for sustainability will drive innovations in recycling-friendly cutting technologies. We may see the development of small glass cutting machines specifically designed to process and repurpose waste glass on-site, turning scrap into new products or components. This could lead to a more circular economy within the glass industry, reducing the need for raw materials and energy-intensive recycling processes.

Biomimicry could inspire new cutting mechanisms that emulate natural processes for more efficient and precise glass shaping. For example, researchers are studying how certain marine organisms manipulate silica at the microscopic level, which could lead to revolutionary glass cutting techniques that work at the molecular scale.

As the Internet of Things (IoT) continues to expand, future small glass cutters will likely become fully integrated into smart factory ecosystems. These connected machines will communicate with other equipment, inventory systems, and even customer order platforms to create a seamless, data-driven production environment. This level of integration will enable just-in-time manufacturing, predictive maintenance, and real-time quality control, further optimizing the glass cutting process.

The trend towards customization and on-demand production is expected to drive the development of more flexible and adaptive small cutting systems. These machines may feature modular designs that can be quickly reconfigured to handle a wide range of glass types and cutting requirements, from large architectural panels to tiny components for electronic devices.

Lastly, as concerns about cybersecurity grow, future small glass cutting machines will likely incorporate advanced security features to protect against potential hacking or data breaches. This will be crucial as these machines become more connected and integral to manufacturing processes.

Conclusion

The future of glass cutting is undeniably bright, with small machines poised to make a big impact across various industries. From emerging technologies that enhance precision and efficiency to sustainable practices that reduce waste, and exciting trends that promise even greater innovations, the evolution of small glass cutting machines is set to revolutionize how we work with glass.

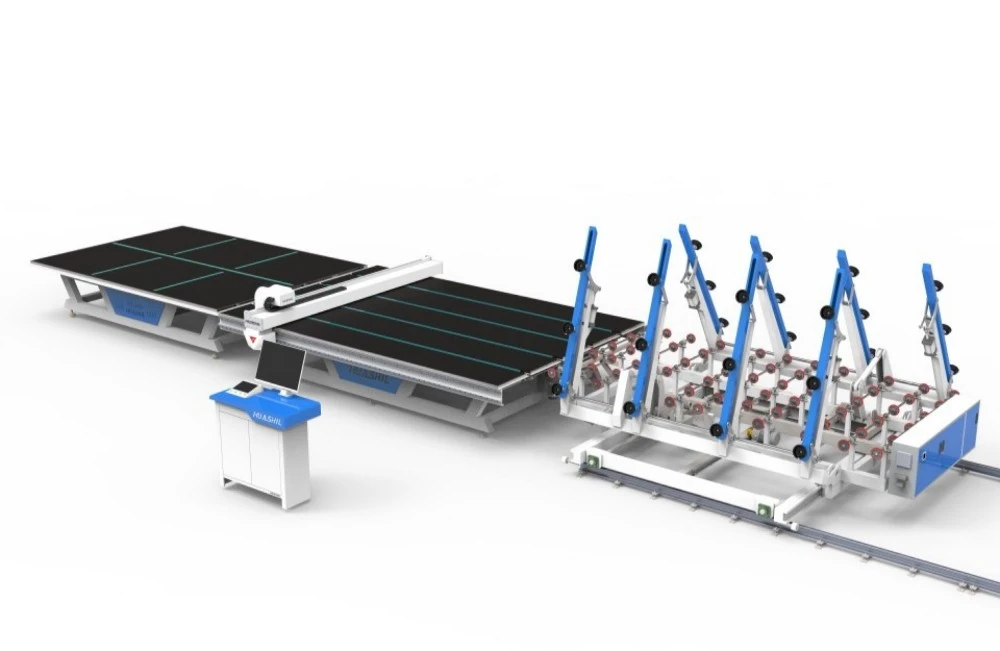

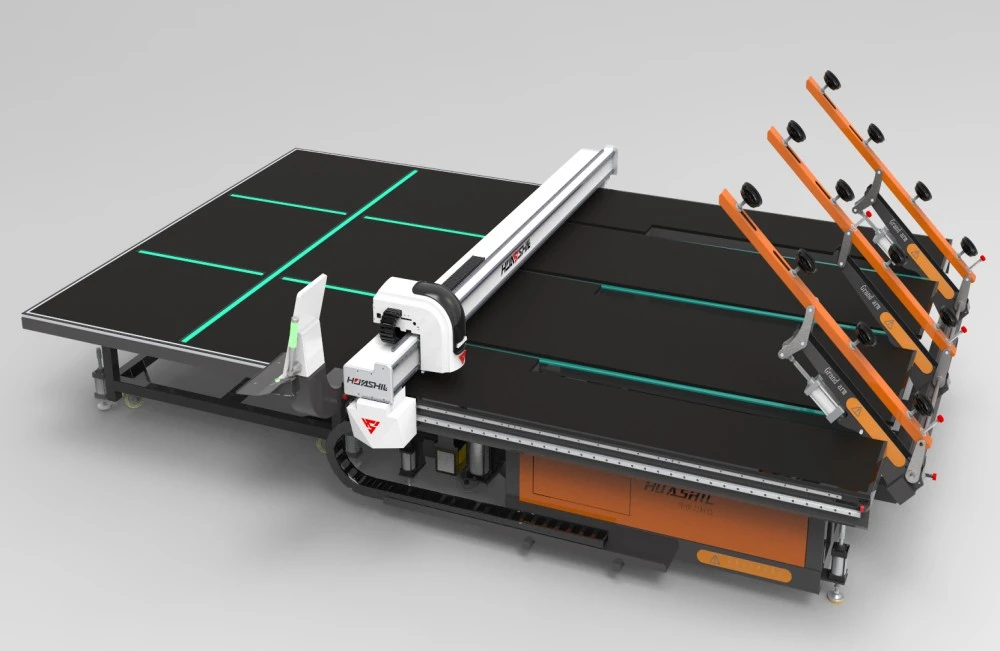

At Shandong Huashil Automation Technology Co., LTD, we're at the forefront of this transformation. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment position us uniquely to meet the growing demands of the glass cutting industry. We understand the needs of our global customers who require advanced techniques, stable quality, and excellent service.

Are you ready to step into the future of glass cutting? Whether you're in architectural glass, automotive manufacturing, or smart technology development, our cutting-edge small glass cutting machines are designed to elevate your operations to new heights of efficiency and precision. Don't let your competition get ahead – invest in the future of your glass cutting capabilities today.

Contact us at salescathy@sdhuashil.com to learn more about how our innovative small glass cutting machines can transform your business. Let's shape the future of glass cutting together!

References

1. Johnson, A. (2023). "Advancements in Compact Glass Cutting Technologies: A Comprehensive Review." Journal of Glass Science and Technology, 45(3), 287-302.

2. Smith, B., & Davis, C. (2022). "The Impact of AI and IoT on Modern Glass Fabrication Processes." International Conference on Smart Manufacturing, Tokyo, Japan.

3. Green, E. (2023). "Sustainable Practices in Glass Cutting: Environmental Benefits of Small-Scale Machinery." Environmental Science & Technology, 57(8), 4210-4225.

4. Lee, S., et al. (2022). "Future Trends in Glass Cutting: Predictions and Potential Applications." Advanced Materials Processing, 180(5), 1245-1260.