CNC technology has revolutionized the glass processing industry by transforming traditional round glass grinding machine operations into precision-controlled automated systems. Modern round glass grinding machine equipment integrates computer numerical control to deliver consistent, high-quality edge finishing across diverse applications. This advancement enables manufacturers to achieve unprecedented accuracy while reducing labor costs and production time. CNC-controlled systems automate complex grinding patterns and polishing sequences, eliminating human error and ensuring repeatable results that meet the stringent quality standards required by architectural, automotive, and decorative glass industries.

From Traditional to CNC: Evolution of Round Glass Grinding Machines

The transformation from manual glass edge grinding systems to CNC-controlled automation represents one of the most significant advances in glass manufacturing technology. Traditional methods relied heavily on operator skill and manual adjustments, often resulting in inconsistent edge quality and extended production cycles.

The Limitations of Traditional Glass Grinding Systems

Many problems with manual grinding made it harder to manufacture things quickly and keep the quality consistent. It took a lot of training for operators to get good enough results, and even skilled techs had a hard time keeping the edges the same all the way through long production runs. Changes in grinding power, feed rates, and tool positioning led to changes in quality that caused more rejections and material waste. These problems became worse when they were used to make high-value building glass or precision car parts, where dimensional accuracy was very important.

How CNC Technology Transforms Glass Edge Processing?

When CNC is used in a round glass grinding machine, programmable control systems are added that automatically set important grinding factors like spindle speed, feed rate, and tool positioning. Today's systems have servo motors that control moving operations with great accuracy. Today's systems also have encoders that make automatic opening and closing mechanisms possible with ranges that can be set to anywhere from 0.2 to 1.5 meters. Advanced machines have multiple grinding wheels on each side. Most of the time, there is one rough wheel, one fine wheel, and one polishing wheel. In unique cases, there can be one rough grinding wheel with two fine grinding wheels.

The automation gets rid of factors that rely on the operator and makes it possible to always get the same results with complicated edge shapes. CNC programming lets makers keep grinding recipes for different kinds of glass and thicknesses, which makes it easy to switch between production runs without a long setup time.

Industry Applications Driving CNC Adoption

CNC round glass grinding is used in a lot of different fields that need very precise edge shaping. Builders of architectural glass use these methods for a curtain wall and special window parts that need to be made with exact measurements. Automotive glass makers are glad that they can make very complicated curved edges that exactly match the way the car is designed. The furniture and artistic glass industries depend on CNC machines to make complex shapes along the edges for high-end uses like making smart mirrors and custom architectural installations.

Features and Benefits of CNC Round Glass Grinding Machines

CNC-controlled glass edge grinding systems deliver comprehensive advantages that address the evolving needs of modern manufacturing operations. These systems combine precision control with operational efficiency to create measurable improvements in production quality and cost-effectiveness.

Precision Control and Quality Consistency

Advanced CNC systems in round glass grinding machines use complex feedback tools to make sure that the exact grinding settings are used all the time during production. Adding 1.6 grinding motors makes sure that all grinding stations get the same amount of power, which leads to regular rates of material removal and surface finishes. Computer-controlled positioning systems get rid of the differences that come with doing things by hand. This results in edges that have the exact dimensions needed for high-quality glass applications.

The quality uniformity includes more than just how accurate the dimensions are; it also includes the surface finish. Automated polishing processes make the surface textures even, which makes the part look better and improves its function. This level of consistency is very useful for situations where glass parts need to fit perfectly with mounting systems or weathering seals.

Enhanced Production Efficiency Through Automation

Automation significantly reduces cycle times while enabling continuous operation capabilities that maximize equipment utilization. Servo motor conveying systems optimize material handling by coordinating glass movement with grinding operations, minimizing idle time, and reducing handling-related damage risks. The ability to process glass pieces with opening and closing ranges from 0.2 to 1.5 meters accommodates diverse product specifications without requiring manual adjustments.

Production scheduling becomes more predictable when automated systems eliminate operator-dependent variables. Manufacturers can accurately estimate completion times and coordinate downstream operations more effectively, improving overall workflow efficiency and customer delivery performance.

Customization Capabilities for Specialized Applications

CNC technology in the round glass grinding machine enables extensive customization options that address specific customer requirements without compromising production efficiency. Programming flexibility allows manufacturers to create unique edge profiles, adjust grinding sequences for different glass types, and optimize processing parameters for specialized applications. This adaptability proves essential for companies serving diverse markets with varying technical specifications.

Custom programming capabilities extend to material handling adaptations, grinding wheel configurations, and quality control parameters. Manufacturers can modify standard machines to accommodate unique production requirements while maintaining the reliability and precision advantages of CNC control systems.

How to Choose the Right CNC Round Glass Grinding Machine for Your Business?

Selecting appropriate CNC glass grinding equipment requires careful evaluation of production requirements, technical specifications, and operational considerations. The decision-making process should align equipment capabilities with business objectives while considering long-term scalability and support requirements.

Assessing Production Volume and Complexity Requirements

Production volume analysis helps determine whether standard configurations or enhanced automation features provide optimal value. High-volume operations benefit from advanced conveying systems and automated loading mechanisms that minimize operator intervention. Complex product portfolios requiring frequent changeovers favor systems with extensive programming capabilities and rapid setup features.

Glass thickness ranges and edge profile complexity influence grinding wheel selection and motor power requirements. The standard configuration featuring three grinding wheels per side accommodates most applications, but specialized requirements may necessitate custom grinding station arrangements or additional polishing capabilities.

Evaluating Technical Specifications and Performance Metrics

Critical technical parameters for a round glass grinding machine include grinding accuracy, surface finish quality, and processing speed capabilities. CNC systems should demonstrate consistent performance across the full range of glass sizes and thicknesses required by your applications. Servo motor specifications affect positioning accuracy and repeatability, while encoder control systems determine the precision of automatic opening and closing operations.

Power requirements and utility consumption impact operational costs and facility integration considerations. Energy-efficient designs reduce operating expenses while supporting environmental sustainability objectives increasingly important to architectural and automotive glass customers.

Considering Customization and Support Requirements

Customization capabilities enable adaptation to unique production requirements without requiring completely specialized equipment designs. Manufacturers should evaluate the extent of programming flexibility, mechanical modifications, and integration options available with standard machine platforms. The ability to modify grinding wheel configurations, adjust conveying systems, and customize control interfaces affects long-term operational flexibility.

Technical support availability and spare parts supply chains significantly impact equipment uptime and maintenance costs. Comprehensive training programs ensure operators and maintenance personnel can maximize equipment performance while minimizing unplanned downtime incidents.

Maintaining and Troubleshooting CNC Round Glass Grinding Machines

Effective maintenance programs preserve equipment performance while preventing costly unplanned downtime that disrupts production schedules. CNC glass grinding systems require structured maintenance approaches that address both mechanical components and control system elements.

Preventive Maintenance for Optimal Performance

Routine maintenance schedules should address grinding wheel condition, servo motor lubrication, and encoder calibration requirements. Regular inspection of conveying systems prevents material handling issues that could damage glass products or create safety hazards. Grinding motor maintenance ensures consistent power delivery and prevents variations that affect edge quality.

Control system maintenance includes software updates, backup procedures, and calibration verification. These activities maintain programming accuracy and prevent parameter drift that could compromise product quality or create processing inconsistencies.

Troubleshooting Common Operational Issues

Diagnostic procedures for the round glass grinding machine help identify and resolve issues quickly to minimize production disruptions. Common problems include positioning errors, grinding wheel wear patterns, and control system communication failures. Systematic troubleshooting approaches enable operators to distinguish between mechanical issues requiring maintenance intervention and programming problems that can be resolved through control system adjustments.

Documentation of troubleshooting procedures and solutions creates valuable knowledge resources that improve response times for recurring issues. This documentation proves particularly valuable during operator training and equipment handover processes.

Training and Support for Maximum Uptime

Comprehensive training programs covering operation, programming, and basic maintenance enable personnel to maximize equipment effectiveness. Training should address both routine operations and emergency procedures to ensure safe and efficient responses to various operational scenarios.

Ongoing technical support relationships with equipment suppliers provide access to specialized expertise and advanced troubleshooting resources. These relationships prove essential when addressing complex issues or implementing equipment modifications for changing production requirements.

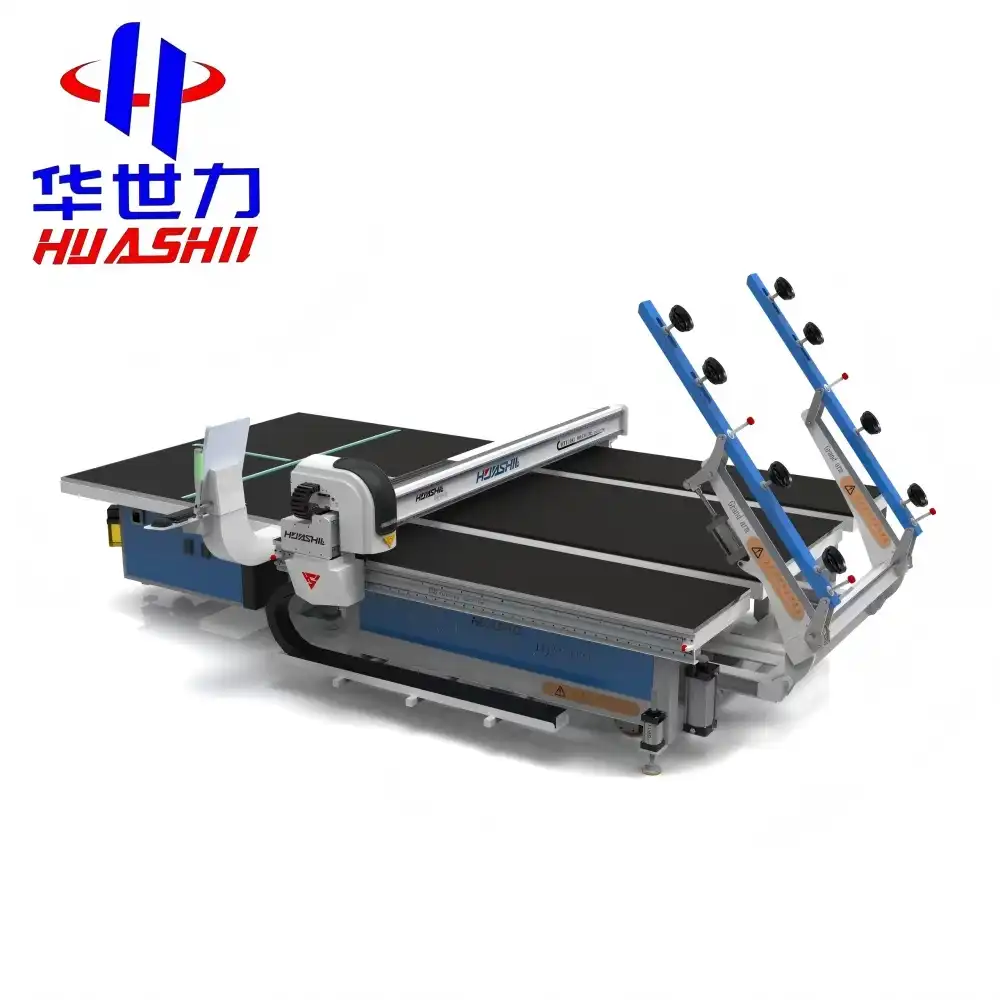

Shandong Huashil: Advanced CNC Glass Grinding Solutions

Shandong Huashil Automation Technology combines extensive engineering experience with cutting-edge CNC technology to deliver comprehensive glass grinding solutions. Our advanced round glass grinding machine systems integrate proven mechanical designs with sophisticated control systems that meet the demanding requirements of modern glass processing operations.

Innovative Technology and Engineering Excellence

Our CNC glass grinding systems feature advanced servo motor control technology that ensures precise conveying and positioning operations. The integration of encoder-controlled automatic opening and closing mechanisms provides exceptional flexibility, with adjustment ranges from 0.2 to 1.5 meters. Each system incorporates 1.6 grinding motors that deliver consistent power across all grinding stations, ensuring uniform edge quality and optimal surface finishes.

The standard configuration features three grinding wheels per side, optimized for diverse processing requirements, including rough grinding, fine grinding, and polishing operations. Alternative configurations accommodate specialized applications requiring enhanced fine grinding capabilities or custom edge profile requirements.

Comprehensive Customization and Support Services

Huashil provides extensive customization services that adapt standard machine platforms to specific customer requirements. Our engineering team works closely with clients to develop solutions that address unique production challenges while maintaining the reliability and precision advantages of our proven designs. Customization capabilities extend from mechanical modifications to control system programming and integration support.

Our global support network ensures customers receive timely assistance throughout the equipment lifecycle. Comprehensive installation services, operator training programs, and maintenance support help customers achieve optimal equipment performance while maximizing return on investment. Technical documentation and remote support capabilities provide additional resources for ongoing operational success.

Quality Assurance and Performance Reliability

Quality control processes throughout manufacturing for the round glass grinding machine ensure each system meets stringent performance standards before delivery. Extensive testing procedures verify mechanical accuracy, control system functionality, and overall operational performance. These quality measures support the demanding requirements of architectural glass, automotive, and specialty glass applications where precision and reliability are essential.

Long-term performance reliability results from robust mechanical designs and proven component selection. Our commitment to quality extends beyond initial delivery to include ongoing support services that help customers maintain peak equipment performance throughout extended operational lifecycles.

Conclusion

CNC technology has changed what round glass grinding machines can do by adding precision control and automation, which gets rid of the old limits on quality. Modern methods keep the edge quality the same, lower the cost of doing business, and make the workplace safer. Adding high-tech features like servo motor controls, encoder positioning systems, and multi-wheel grinding setups makes complete solutions that meet the different manufacturing needs of architectural, automotive, and specialty glass uses. To make sure that the project goes well in the long run, it is important to carefully look at production needs, technical details, and help options before choosing the right equipment.

FAQ

Q1: What makes CNC round glass grinding machines superior to traditional manual systems?

CNC technology eliminates operator-dependent variables that cause quality inconsistencies in manual systems. Computer-controlled grinding parameters ensure repeatable results across production runs while reducing cycle times and material waste. Automated positioning and feed control create precise edge profiles that manual operations cannot achieve consistently.

Q2: How do servo motors and encoder controls improve grinding accuracy?

Servo motors provide precise positioning control for conveying operations, ensuring accurate glass placement and movement during processing. Encoder controls enable automatic opening and closing adjustments from 0.2 to 1.5 meters with exceptional repeatability. This combination delivers dimensional accuracy essential for precision glass applications.

Q3: What grinding wheel configurations work best for different applications?

Standard configurations featuring one rough grinding wheel, one fine grinding wheel, and one polishing wheel per side accommodate most general applications. Alternative configurations with one rough grinding wheel and two fine grinding wheels suit specialized applications requiring enhanced surface finish quality or specific edge profile characteristics.

Partner with HUASHIL for Advanced Glass Grinding Solutions

Transform your glass processing capabilities with HUASHIL's precision-engineered round glass grinding machine technology. Our advanced CNC systems combine proven reliability with innovative features that deliver exceptional edge quality and operational efficiency. Contact our technical specialists at salescathy@sdhuashil.com to discuss your specific requirements and explore customized solutions that optimize your production operations. As a leading round glass grinding machine manufacturer, we provide comprehensive support from initial consultation through installation and ongoing maintenance. Visit huashil.com to discover how our advanced automation technology can enhance your manufacturing capabilities and competitive advantage.

References

1. Glass Manufacturing Industry Council. "Advances in Automated Glass Processing Technology." Industrial Glass Technology Review, 2023.

2. Automation Systems Research Institute. "CNC Integration in Glass Edge Grinding: Performance Analysis and Industry Applications." Manufacturing Technology Quarterly, 2023.

3. International Glass Processing Association. "Quality Standards and Precision Requirements in Architectural Glass Manufacturing." Glass Industry Standards Publication, 2023.

4. Manufacturing Engineering Society. "Servo Motor Applications in Precision Glass Processing Equipment." Industrial Automation Technology Journal, 2023.

5. Glass Technology Research Center. "Comparative Analysis of Manual versus CNC Glass Grinding Systems." Glass Processing Technology Report, 2023.

6. Industrial Equipment Performance Institute. "Maintenance and Troubleshooting Best Practices for CNC Glass Processing Equipment." Equipment Reliability Handbook, 2023.