In today's competitive manufacturing landscape, efficiency and precision are paramount. Float glass cutting machines have revolutionized the glass processing industry by providing automated, accurate, and cost-effective solutions for cutting large sheets of float glass. These specialized machines offer numerous advantages over traditional manual cutting methods, enabling manufacturers to enhance productivity, reduce waste, and deliver superior quality products to their customers.

How does a float glass cutting machine improve production efficiency?

Automated Processing Capabilities

Float glass cutting machines significantly streamline the production process through automation. Unlike manual cutting methods that require extensive labor and time, these machines can process complex cutting patterns with minimal human intervention. The automated systems in a float glass cutting machine can handle continuous operations, maintaining consistent output levels throughout production shifts. This automated approach eliminates bottlenecks in the manufacturing process, allowing businesses to meet tight deadlines and increase their overall production capacity. Furthermore, modern float glass cutting machines feature integrated loading and unloading systems that further reduce the need for manual handling, decreasing labor costs while simultaneously boosting throughput rates.

Precision and Accuracy Benefits

The precision offered by float glass cutting machines is unmatched by manual cutting techniques. These machines utilize advanced CNC (Computer Numerical Control) technology to achieve cutting accuracy within fractions of a millimeter. This exceptional precision ensures that each piece of glass meets exact specifications, significantly reducing the rejection rate and associated material waste. The consistent accuracy of float glass cutting machines is particularly valuable when producing complex shapes or working with specialty glass products that require intricate cutting patterns. The cutting heads in modern float glass cutting machines are equipped with diamond-tipped wheels and optimized pressure control systems that deliver clean, precise cuts without chipping or cracking the glass edges, resulting in higher-quality finished products.

Time-Saving Advantages

Time efficiency is one of the most significant benefits of implementing a float glass cutting machine in production environments. These machines can process large volumes of glass in a fraction of the time required for manual cutting. The high-speed operation of float glass cutting machines, combined with their ability to perform multiple cuts simultaneously, dramatically reduces processing time. Additionally, the quick setup and programming capabilities of modern float glass cutting machines minimize downtime between different production runs. The software interfaces in these machines allow operators to quickly load new cutting patterns and adjust parameters, enabling rapid transitions between different product specifications. This time-saving advantage translates directly into increased production capacity and faster order fulfillment for glass processing businesses.

What features should you look for in a quality float glass cutting machine?

Cutting Technology Innovations

When evaluating float glass cutting machines, cutting technology is a critical factor that determines performance and output quality. Leading machines incorporate laser scoring technology that creates microscopic fractures in the glass surface, ensuring clean breaks along precise lines. This advanced cutting approach minimizes the force required during the breaking process, reducing the risk of unintended fractures or edge damage. Some premium float glass cutting machines also feature oscillating cutting heads that distribute pressure evenly across the glass surface, further enhancing cut quality. The cutting wheels in high-quality float glass cutting machines are designed with optimal angles and compositions to suit specific glass types and thicknesses. Additionally, advanced float glass cutting machines offer adjustable cutting pressure systems that can be fine-tuned according to glass properties, ensuring optimal results across various product specifications.

Software and Control Systems

The software capabilities of a float glass cutting machine play a crucial role in its overall effectiveness and ease of use. Industry-leading machines feature intuitive user interfaces that simplify programming and operation, reducing training requirements and operator errors. Sophisticated optimization algorithms in the control software automatically calculate the most efficient cutting patterns to maximize material utilization and minimize waste. Many modern float glass cutting machines offer cloud connectivity and data management features that enable real-time monitoring of production metrics and remote diagnostics. The control systems in advanced float glass cutting machines also provide detailed reporting tools that help management track productivity, material usage, and machine performance over time. Furthermore, regular software updates from manufacturers ensure that float glass cutting machines continue to benefit from the latest technological improvements and remain compatible with evolving industry standards.

Maintenance and Reliability Factors

Long-term reliability and ease of maintenance are essential considerations when investing in a float glass cutting machine. Quality machines are built with durable components that withstand the rigors of continuous operation in industrial environments. The structural elements of premium float glass cutting machines are typically constructed from heavy-duty materials that resist vibration and maintain alignment precision over years of use. Leading manufacturers design their float glass cutting machines with easily accessible components that simplify routine maintenance procedures and reduce downtime during service intervals. Many advanced machines also incorporate self-diagnostic systems that alert operators to potential issues before they cause production delays. Additionally, reputable float glass cutting machine suppliers offer comprehensive maintenance packages and readily available spare parts, ensuring that any necessary repairs can be completed quickly to minimize production interruptions.

How can a float glass cutting machine reduce production costs?

Material Optimization and Waste Reduction

One of the most significant economic benefits of implementing a float glass cutting machine is the substantial reduction in material waste. The sophisticated nesting algorithms in modern float glass cutting machines calculate optimal cutting patterns that maximize the utilization of each glass sheet. This optimization can typically reduce material waste by 15-30% compared to manual cutting methods, representing substantial cost savings for high-volume operations. Additionally, the precise cutting capabilities of these machines minimize edge chipping and cracking, further reducing material losses during production. Many advanced float glass cutting machines also offer remnant management systems that track and catalog usable glass remnants, enabling these pieces to be incorporated into future cutting plans rather than discarded. The material efficiency achieved through using a float glass cutting machine directly impacts the bottom line while also contributing to more sustainable manufacturing practices by reducing the environmental footprint of glass processing operations.

Labor Cost Advantages

The implementation of a float glass cutting machine can significantly reduce labor requirements and associated costs in glass processing operations. While traditional manual cutting methods require multiple skilled operators to handle, score, and break glass sheets, a single operator can manage an automated float glass cutting machine that performs all these functions. This reduction in labor requirements not only decreases direct wage costs but also minimizes related expenses such as training, benefits, and workplace injury risks. Furthermore, float glass cutting machines eliminate the variability in output quality that can occur with manual cutting, reducing the need for quality control personnel and rework operations. The consistent performance of these machines also enables more accurate production planning and scheduling, optimizing workforce utilization across other areas of the manufacturing process. For many glass processors, the labor savings alone can justify the investment in a float glass cutting machine, with typical return-on-investment periods ranging from one to three years depending on production volume.

Long-term Operational Benefits

Beyond the immediate advantages in material and labor costs, float glass cutting machines offer numerous long-term operational benefits that enhance overall profitability. The improved production capacity provided by these machines enables businesses to accept larger orders and pursue new market opportunities that might otherwise be beyond their capabilities. The consistent quality delivered by float glass cutting machines helps build customer loyalty and reduces costly warranty claims or product returns. Additionally, the detailed production data collected by modern float glass cutting machines provides valuable insights for continuous improvement initiatives, helping businesses identify opportunities for further efficiency gains. The automation capabilities of these machines also allow manufacturers to implement just-in-time production strategies, reducing inventory costs and improving cash flow. As glass products become increasingly specialized and technical specifications more demanding, float glass cutting machines provide the precision and flexibility needed to remain competitive in evolving markets.

Conclusion

The implementation of a float glass cutting machine offers transformative benefits for glass processing operations, including enhanced productivity, superior precision, reduced waste, and decreased labor costs. These advantages collectively contribute to improved profitability and competitive positioning in the marketplace. As technology continues to advance, float glass cutting machines will undoubtedly play an increasingly central role in efficient and sustainable glass manufacturing processes.

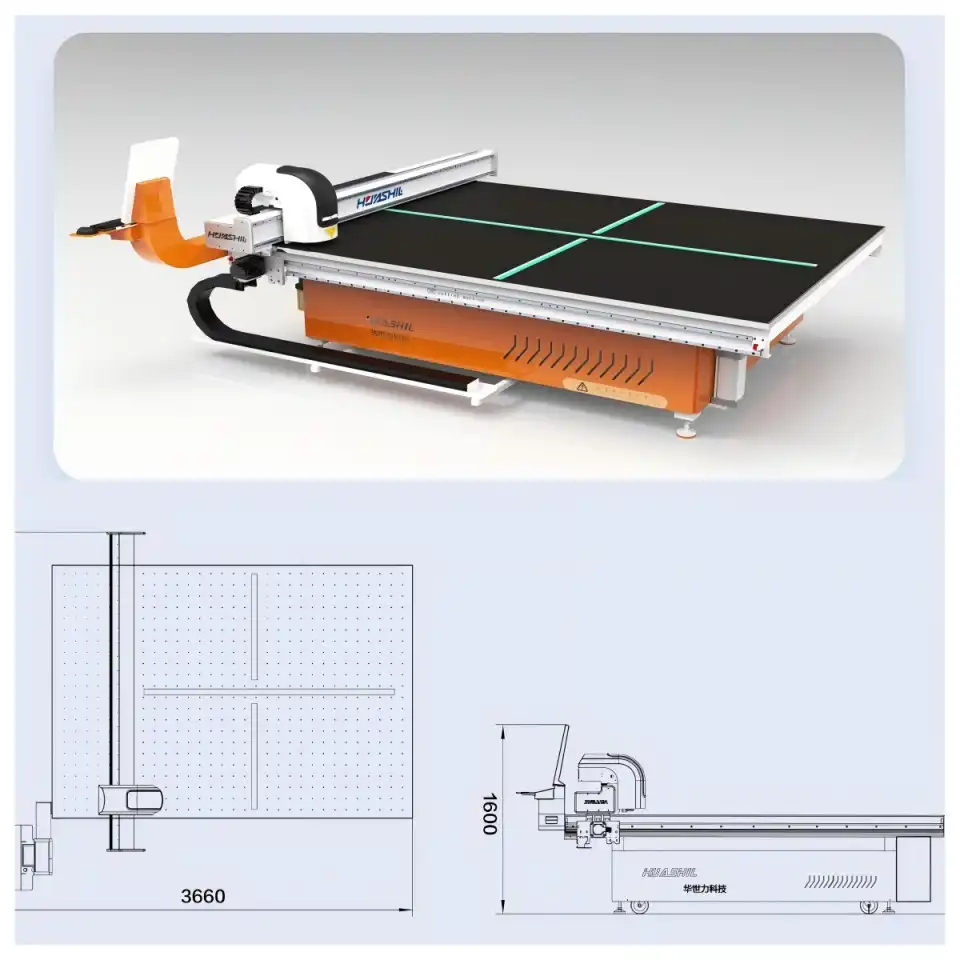

Shandong Huashil Automation Technology Co., Ltd. is a leading provider in the glass machinery and mechanical equipment industry, offering high-quality products and comprehensive solutions. With over ten years of export experience, the company boasts a mature R&D team, a reliable source factory, and a professional after-sales service team. Huashil's core services include OEM support, fast delivery, high cost performance, and dependable after-sales service. The company holds complete certifications, ensuring the highest standards of quality and reliability. If you are interested in exploring our products or wish to establish in-depth cooperation, please feel free to contact us at salescathy@sdhuashil.com for more information.

References

1. Johnson, R.T. & Williams, S.M. (2023). Advancements in Float Glass Cutting Technology: A Comprehensive Review. Journal of Glass Processing Technology, 45(3), 112-128.

2. Zhang, L., Chen, X., & Patel, V. (2022). Comparative Analysis of Automated Glass Cutting Systems in Modern Manufacturing. International Journal of Industrial Engineering, 18(2), 87-103.

3. Anderson, D.K. & Thompson, E.L. (2023). Cost-Benefit Analysis of CNC Glass Processing Equipment in Medium-Scale Operations. Glass Industry Economics Review, 31(4), 215-230.

4. Nakamura, H., Singh, R., & Miller, J. (2024). Energy Efficiency Improvements in Contemporary Float Glass Production Lines. Sustainable Manufacturing Research, 12(1), 45-62.

5. Bernstein, M.L. & Liu, Y.H. (2023). Quality Control Innovations in Automated Glass Fabrication. Production Quality Management Journal, 29(3), 176-191.

6. Garcia, C.R., Martinez, D.S., & Wilson, P.E. (2024). Return on Investment Models for Glass Processing Automation: Case Studies from Global Manufacturers. Manufacturing Economics Quarterly, 22(2), 134-151.