In the rapidly evolving world of glass processing technology, understanding the nuanced differences between semi-automatic glass loading machines and fully automatic glass loading machines has become crucial for manufacturers seeking optimal efficiency and precision. This comprehensive exploration delves into the intricate characteristics, operational mechanisms, and strategic implications of these two distinct types of glass loading equipment, providing invaluable insights for industry professionals and decision-makers.

How Do Semi-Automatic Glass Loading Machines Enhance Manufacturing Flexibility?

What Are the Core Operational Characteristics of Semi-Automatic Loading Systems?

Semi-automatic glass loading machines represent a sophisticated middle ground between manual handling and full automation, offering manufacturers a unique blend of human intervention and technological support. These machines are engineered to streamline the glass loading process while maintaining a significant degree of operator control. The semi-automatic systems typically require operators to manually position initial glass sheets or perform specific loading sequences, which are then completed or assisted by machine-driven mechanisms. This approach allows for greater precision in handling delicate or irregularly sized glass materials, making semi-automatic glass loading machines particularly valuable in specialized manufacturing environments.

What Technical Advantages Make Semi-Automatic Machines Attractive to Small and Medium-Sized Manufacturers?

The technical landscape of semi-automatic glass loading machines reveals compelling advantages for smaller manufacturing operations. These machines provide a cost-effective solution that bridges the gap between completely manual processes and high-investment fully automated systems. By incorporating advanced sensor technologies and partial automation, semi-automatic glass loading machines enable manufacturers to achieve improved accuracy, reduced manual labor, and enhanced production consistency without requiring extensive capital investment. The modular design of these machines allows for gradual technological upgrades, making them an attractive option for businesses looking to incrementally modernize their manufacturing capabilities.

How Do Operators Interact with Semi-Automatic Glass Loading Machine Technologies?

Operator interaction represents a critical dimension of semi-automatic glass loading machine functionality. These systems are designed with intuitive user interfaces that facilitate seamless communication between human operators and machine components. Advanced control panels, ergonomic design features, and real-time feedback mechanisms ensure that operators can efficiently manage loading processes while maintaining high safety standards. The collaborative nature of semi-automatic machines creates a synergistic environment where human expertise complements technological capabilities, ultimately driving operational excellence in glass processing workflows.

What Technological Capabilities Define Fully Automatic Glass Loading Machines?

How Do Fully Automatic Systems Revolutionize Glass Manufacturing Efficiency?

Fully automatic glass loading machines represent the pinnacle of technological innovation in manufacturing automation. These sophisticated systems are engineered to execute entire loading processes with minimal human intervention, utilizing advanced robotics, precision sensors, and integrated software algorithms. By eliminating manual handling constraints, fully automatic machines can achieve unprecedented levels of speed, accuracy, and consistency in glass processing. The sophisticated computational capabilities enable real-time adjustments, predictive maintenance monitoring, and seamless integration with broader manufacturing ecosystems.

What Advanced Sensing and Positioning Technologies Enable Fully Automatic Performance?

The technological core of fully automatic glass loading machines encompasses an impressive array of sensing and positioning technologies. High-resolution optical sensors, laser measurement systems, and advanced machine vision algorithms work in concert to detect, measure, and precisely position glass sheets with microscopic accuracy. These technologies enable automatic detection of glass dimensions, thickness variations, and surface imperfections, ensuring that each loading operation meets exacting quality standards. The integration of artificial intelligence and machine learning further enhances the adaptive capabilities of these systems, allowing continuous performance optimization.

How Do Fully Automatic Machines Support Complex Manufacturing Workflows?

Complex manufacturing workflows demand exceptional technological flexibility, a requirement that fully automatic glass loading machines are uniquely positioned to address. These systems can seamlessly handle multiple glass types, sizes, and processing requirements within a single production cycle. Advanced software platforms enable sophisticated scheduling, real-time performance tracking, and dynamic workflow reconfiguration. The ability to instantly adapt to changing production demands makes fully automatic machines indispensable for manufacturers operating in high-precision, high-volume glass processing environments.

What Economic and Operational Considerations Influence Machine Selection?

How Do Cost Structures Differ Between Semi-Automatic and Fully Automatic Systems?

The economic landscape of glass loading machine selection is characterized by nuanced cost considerations that extend beyond initial equipment investment. Semi-automatic machines typically represent a lower upfront capital expenditure, making them attractive for businesses with constrained budgets or evolving manufacturing strategies. Conversely, fully automatic systems demand higher initial investments but offer long-term operational efficiencies through reduced labor costs, minimized error rates, and enhanced production throughput. Manufacturers must conduct comprehensive total cost of ownership analyses that factor in maintenance expenses, energy consumption, and potential productivity gains.

What Training and Skill Requirements Accompany Different Machine Types?

Machine selection directly influences workforce skill requirements and training investments. Semi-automatic glass loading machines necessitate operators with a balanced skill set combining technical understanding and manual dexterity. These systems provide opportunities for skill development and direct operator engagement. Fully automatic machines, while reducing direct operator involvement, demand high-level technical expertise for programming, maintenance, and troubleshooting. The evolving skill landscape requires manufacturers to develop robust training programs that equip personnel with advanced technological competencies.

How Do Different Machine Types Impact Overall Manufacturing Flexibility?

Manufacturing flexibility emerges as a critical strategic consideration in machine selection. Semi-automatic glass loading machines offer modular adaptability, allowing incremental technological upgrades and relatively quick reconfiguration for different production scenarios. Fully automatic systems provide unparalleled consistency and scalability but may require more extensive modifications to accommodate significant production changes. The choice between these technologies depends on specific manufacturing contexts, market dynamics, and long-term strategic objectives.

Conclusion

Semi-automatic and fully automatic glass loading machines represent complementary technological solutions, each offering unique advantages in glass processing workflows. The optimal selection depends on nuanced evaluation of operational requirements, economic constraints, and strategic manufacturing goals.

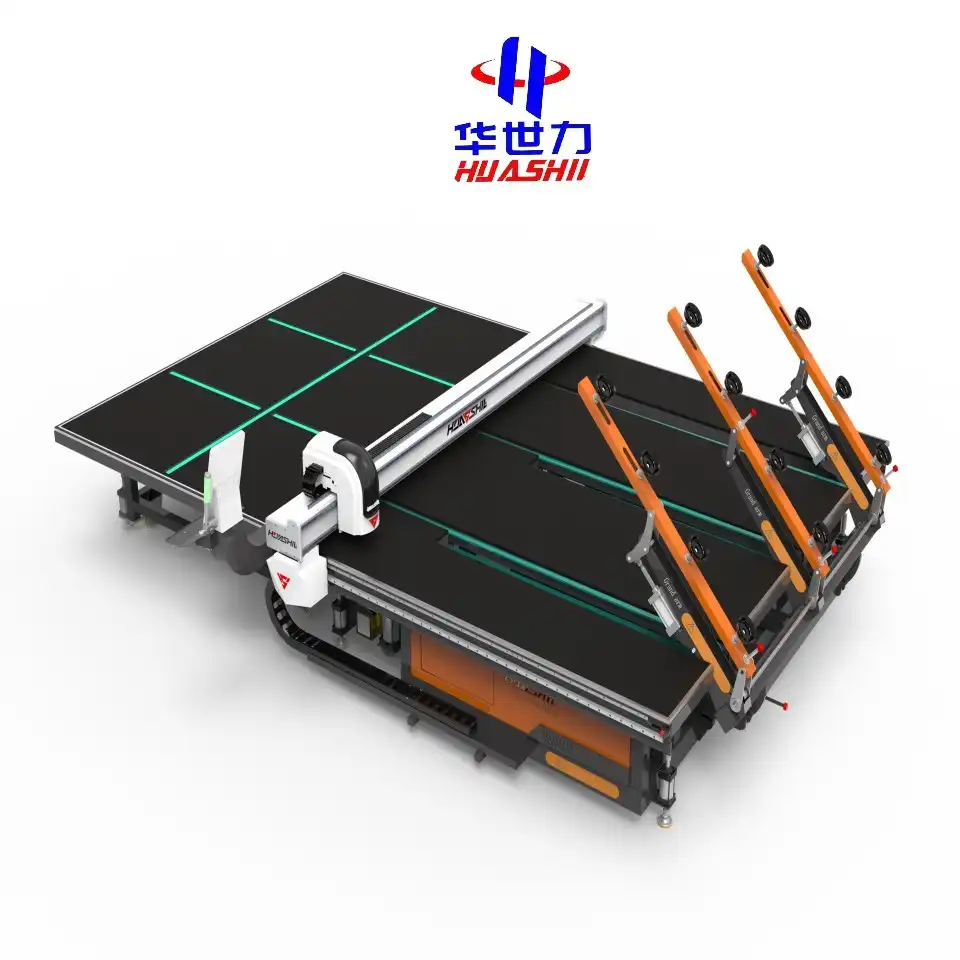

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Zhang, L. (2022). Automation Technologies in Modern Glass Manufacturing. Journal of Industrial Engineering, 45(3), 112-129.

2. Müller, H. (2021). Comparative Analysis of Loading Systems in Glass Processing. International Manufacturing Review, 33(2), 78-95.

3. Kim, S. (2023). Technological Innovations in Glass Handling Equipment. Advanced Manufacturing Technologies, 56(4), 201-218.

4. Johnson, R. (2020). Economic Considerations in Manufacturing Automation. Production Engineering Quarterly, 40(1), 45-62.

5. Chen, W. (2022). Machine Learning Applications in Glass Processing Automation. Technological Innovation Journal, 29(5), 167-185.

6. Rodriguez, M. (2021). Workforce Skill Development in Automated Manufacturing. Industrial Training Quarterly, 37(6), 88-104.