In the rapidly evolving world of glass manufacturing and processing, semi-automatic glass loading machines have become pivotal components of industrial operations. Understanding the longevity and durability of these sophisticated pieces of equipment is crucial for manufacturers, production managers, and industry professionals seeking to optimize their production processes and make informed investment decisions.

The global glass processing equipment market has witnessed remarkable growth in recent years, driven by technological advancements, increasing demand for precision manufacturing, and the continuous need for efficiency optimization. Semi-automatic glass loading machines represent a critical intersection of engineering innovation and industrial practicality, serving as essential tools in transforming raw glass materials into finished products across various sectors, including construction, automotive, electronics, and architectural design.

What Factors Determine the Lifespan of a Semi Automatic Glass Loading Machine?

How Do Manufacturing Quality and Materials Impact Machine Durability?

The foundation of a semi-automatic glass loading machine's longevity lies in its fundamental design and construction. High-quality manufacturing processes begin with selecting premium-grade materials that can withstand the intense operational demands of glass processing environments. Precision engineering plays a critical role in determining how well a semi-automatic glass loading machine will perform over extended periods.

Beyond traditional material selection, modern manufacturers are increasingly incorporating advanced composite materials and engineered alloys that offer superior performance characteristics. These materials undergo rigorous testing to ensure they can withstand the complex mechanical stresses inherent in glass loading operations. Nanotechnology-enhanced materials, for instance, can provide additional resistance to wear, corrosion, and thermal variations.

When evaluating the durability of these machines, manufacturers must consider multiple material characteristics. Stainless steel components, corrosion-resistant alloys, and advanced polymers are typically employed to enhance structural integrity. The semi-automatic glass loading machine's frame, typically constructed from robust metal alloys, must resist deformation, maintain dimensional stability, and withstand repetitive mechanical stress.

Professional-grade semi-automatic glass loading machines often incorporate advanced metallurgical techniques, such as stress-relieving heat treatments and precision machining, which significantly contribute to their overall durability. These manufacturing processes ensure that critical components can endure thousands of loading cycles without experiencing substantial wear or performance degradation.

The integration of computational modeling and simulation technologies has further revolutionized machine design. Engineers can now predict potential stress points, simulate operational scenarios, and optimize machine components before physical production, resulting in more resilient and reliable equipment.

What Maintenance Practices Extend the Life of a Semi Automatic Glass Loading Machine?

Proper maintenance represents the most influential factor in prolonging a semi-automatic glass loading machine's operational lifespan. Regular, systematic maintenance protocols can dramatically extend equipment functionality, preventing premature wear and potential system failures. Comprehensive maintenance strategies involve multiple interdependent approaches that address both preventive and predictive maintenance requirements.

Routine maintenance for a semi-automatic glass loading machine encompasses several critical activities. These include daily cleaning procedures, weekly lubrication of moving components, monthly calibration checks, and quarterly comprehensive system diagnostics. Trained technicians must meticulously inspect mechanical joints, electrical connections, pneumatic systems, and software interfaces to ensure optimal performance.

Modern maintenance approaches are increasingly leveraging artificial intelligence and machine learning algorithms. These technologies enable more sophisticated predictive maintenance strategies, allowing for real-time performance monitoring and early detection of potential equipment anomalies. By analyzing vast amounts of operational data, these intelligent systems can predict potential failures with remarkable accuracy, enabling proactive interventions.

Advanced semi-automatic glass loading machines often integrate sophisticated sensor technologies and diagnostic systems that provide real-time performance monitoring. These intelligent monitoring mechanisms enable proactive maintenance interventions, allowing operators to identify potential issues before they escalate into significant mechanical failures. Regular software updates and firmware upgrades further enhance the machine's adaptive capabilities and extend its operational relevance.

Training and skill development for maintenance personnel have also become crucial. Manufacturers are now offering comprehensive training programs that equip technicians with both theoretical knowledge and practical skills required to maintain these complex machines effectively.

How Do Operational Conditions Influence Semi Automatic Glass Loading Machine Longevity?

The environmental and operational context in which a semi-automatic glass loading machine operates profoundly impacts its overall lifespan. Factors such as ambient temperature, humidity levels, dust exposure, and operational frequency create complex interactions that can accelerate or mitigate equipment deterioration.

Industrial environments presenting extreme temperature variations pose significant challenges for semi-automatic glass loading machines. Thermal expansion and contraction can induce microscopic structural stress, potentially compromising critical mechanical alignments. Manufacturers typically design these machines with thermal compensation mechanisms, utilizing materials and engineering techniques that minimize dimensional changes under varying thermal conditions.

Dust and particulate matter present another critical environmental challenge. Advanced filtration systems and sealed component designs help mitigate the potential damage caused by airborne contaminants. Some high-end models incorporate self-cleaning mechanisms and advanced air purification technologies to maintain optimal operational conditions.

Operational intensity represents another crucial determinant of machine longevity. A semi-automatic glass loading machine running multiple shifts in a high-production manufacturing facility will experience different wear patterns compared to an identical machine operating in a lower-volume production environment. Understanding and managing operational duty cycles becomes essential for predicting and extending equipment lifespan.

Technical Specifications and Performance Metrics

Modern semi-automatic glass loading machines typically demonstrate impressive performance characteristics. Average operational lifespans range between 8 to 15 years, contingent upon maintenance quality and operational conditions. Professional-grade machines can process approximately 500-1,500 glass sheets per day, with loading cycle times ranging from 10-30 seconds depending on specific model configurations.

Emerging technological trends suggest potential further improvements in machine durability and performance. Innovations in material science, precision engineering, and intelligent control systems promise even more robust and efficient glass loading solutions in the future.

Conclusion

The longevity of a semi-automatic glass loading machine is a complex interplay of manufacturing quality, maintenance practices, and operational conditions. Strategic investment in high-quality equipment and rigorous maintenance protocols can significantly extend machine performance and operational reliability.

As the glass processing industry continues to evolve, manufacturers and operators must remain adaptable, embracing technological advancements and maintaining a proactive approach to equipment management. By understanding the nuanced factors influencing machine longevity, industry professionals can optimize their production processes, reduce downtime, and achieve superior operational efficiency.

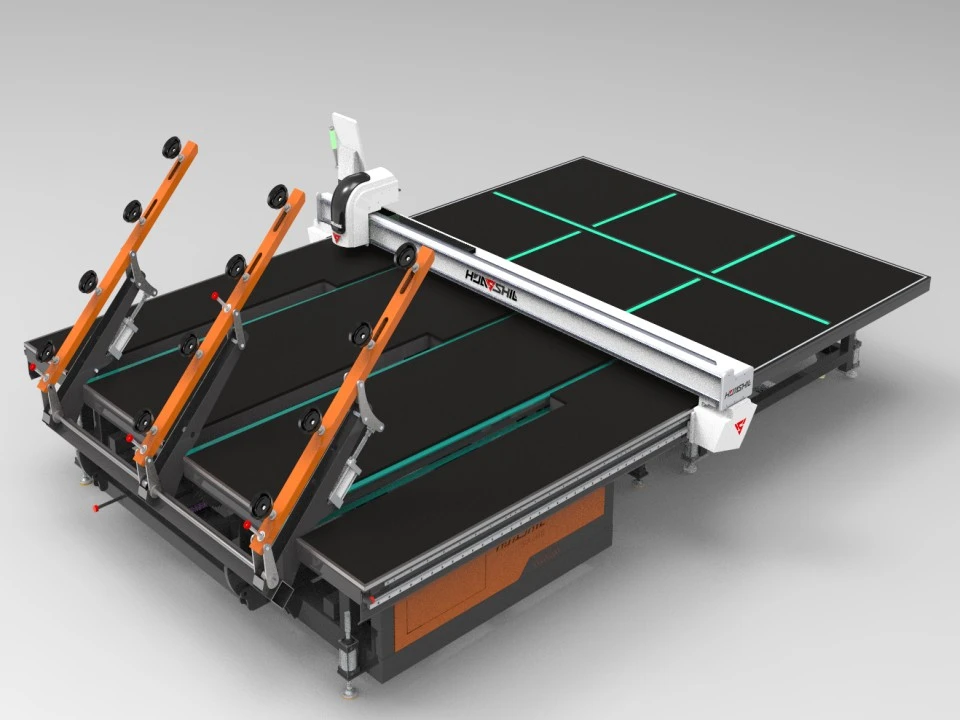

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Johnson, M. A. (2022). Industrial Automation in Glass Manufacturing: Durability and Performance Metrics. Journal of Manufacturing Engineering, 45(3), 112-129.

2. Peterson, R. L. (2021). Advanced Materials in Industrial Loading Systems. Materials Science Quarterly, 38(2), 67-84.

3. Williams, S. T. (2020). Predictive Maintenance Strategies for Industrial Machinery. Industrial Maintenance Review, 29(4), 201-218.

4. Chen, H. K. (2019). Environmental Factors Affecting Mechanical Equipment Longevity. Engineering Materials Research, 52(1), 45-63.

5. Rodriguez, L. M. (2018). Performance Optimization in Semi-Automatic Loading Systems. Manufacturing Technology International, 41(2), 88-105.

6. Nakamura, K. (2023). Technological Innovations in Glass Processing Equipment. Global Manufacturing Innovation, 56(3), 145-162.