In the intricate world of glass and mirror manufacturing, cutting machines play a pivotal role in transforming raw materials into precision-crafted products. This comprehensive exploration delves into the most common types of mirror loading and cutting machines, unveiling the technological innovations that drive efficiency, accuracy, and productivity in the glass processing industry. From traditional manual techniques to advanced computer-controlled systems, mirror cutting machines have revolutionized how manufacturers approach glass and mirror fabrication.

How Do Advanced Mirror Loading and Cutting Machines Enhance Manufacturing Precision?

What Are the Key Technological Components of Modern Mirror Cutting Machines?

Mirror loading and cutting machines represent the pinnacle of manufacturing technology, integrating sophisticated mechanical and digital systems to achieve unprecedented levels of precision. The core technological components include advanced optical sensors, computer numerical control (CNC) systems, and high-precision cutting mechanisms that work in seamless harmony to transform raw mirror sheets into perfectly shaped products.

Modern mirror loading and cutting machines utilize multiple sensor technologies to ensure absolute accuracy. Laser measurement systems scan the mirror surface with microscopic precision, detecting even the slightest surface irregularities. These sensors communicate real-time data to the CNC control system, which makes instantaneous adjustments to the cutting parameters. The integration of machine learning algorithms allows these systems to continuously improve their cutting strategies, learning from each operation to enhance future performance.

The mechanical components of these machines are equally impressive. High-tensile steel frames provide exceptional stability, minimizing vibrations that could compromise cutting accuracy. Diamond-tipped cutting wheels, crafted from industrial-grade materials, ensure clean and precise cuts across various mirror thicknesses. Pneumatic and hydraulic systems manage the delicate balance of pressure and movement, allowing for intricate cutting patterns that would be impossible with manual techniques.

How Do Automated Loading Systems Improve Efficiency in Mirror Manufacturing?

Automated loading systems have transformed the mirror cutting process by eliminating human error and significantly reducing production time. These sophisticated mechanisms utilize advanced robotic arms equipped with vacuum-based gripping technology to handle mirrors of various sizes and thicknesses with exceptional care and precision.

The loading process begins with strategic mirror sheet positioning, where optical recognition systems analyze the mirror's dimensions, thickness, and surface characteristics. Sophisticated algorithms calculate the most efficient cutting pattern, minimizing material waste and maximizing yield. Robotic arms then delicately transport the mirror sheet to the cutting station, using multiple axis movements that ensure minimal stress on the fragile material.

Integrated safety systems play a crucial role in these automated loading mechanisms. Pressure-sensitive sensors detect any potential misalignment or unexpected resistance, immediately halting the operation to prevent damage to the mirror or the machine. This level of automation not only improves efficiency but also significantly reduces the risk of workplace accidents associated with manual mirror handling.

What Role Do Software Solutions Play in Modern Mirror Cutting Machines?

Software has become the brain behind modern mirror loading and cutting machines, transforming them from mechanical tools to intelligent manufacturing systems. Advanced CAD/CAM software enables designers and manufacturers to create complex cutting patterns with unprecedented detail and accuracy.

These software solutions offer comprehensive features like 3D modeling, real-time simulation, and predictive maintenance tracking. Designers can input exact specifications, and the software generates optimal cutting paths that minimize material waste and maximize production efficiency. Machine learning algorithms continuously analyze performance data, suggesting improvements in cutting strategies and predicting potential maintenance requirements before they become critical issues.

Cloud connectivity has further expanded the capabilities of mirror loading and cutting machine software. Manufacturers can now monitor multiple machines remotely, collect performance data, and implement updates across entire production lines simultaneously. This level of connectivity ensures consistent quality, allows for rapid problem-solving, and enables manufacturers to adapt quickly to changing market demands.

What Innovative Technologies Are Transforming Mirror Cutting Machine Design?

How Are Laser Technologies Revolutionizing Mirror Cutting Processes?

Laser cutting technologies have emerged as a game-changing innovation in mirror loading and cutting machines. Unlike traditional mechanical cutting methods, laser systems offer unprecedented precision, allowing for intricate designs and minimal material loss. These advanced systems utilize high-powered laser beams that can cut through mirror surfaces with microscopic accuracy.

The fundamental principle behind laser cutting involves focusing an intense beam of light to generate extreme heat, which vaporizes or melts the mirror material along a predetermined path. Computer-controlled mirrors and lenses guide the laser beam with remarkable precision, enabling complex geometrical shapes and intricate patterns that were previously impossible to achieve.

Different laser technologies, such as CO2 lasers and fiber lasers, offer unique advantages for mirror cutting. CO2 lasers excel in cutting thicker mirror materials, while fiber lasers provide exceptional precision for thinner sheets. The choice depends on specific manufacturing requirements, material characteristics, and desired output quality.

What Emerging Trends Are Shaping the Future of Mirror Cutting Machines?

The mirror cutting machine industry is experiencing rapid technological evolution, driven by demands for greater efficiency, sustainability, and customization. Artificial intelligence and machine learning are increasingly being integrated into mirror loading and cutting machines, enabling predictive maintenance, real-time quality control, and adaptive manufacturing processes.

Sustainability is becoming a critical focus, with manufacturers developing machines that minimize energy consumption and material waste. Advanced nesting algorithms optimize cutting patterns to reduce scrap materials, while energy-efficient drive systems and regenerative braking technologies lower overall power requirements.

Modular design is another emerging trend, allowing manufacturers to customize mirror cutting machines for specific production needs. Interchangeable cutting heads, flexible loading systems, and adaptable software platforms provide unprecedented flexibility in mirror manufacturing.

How Are Industry 4.0 Principles Influencing Mirror Cutting Machine Development?

Industry 4.0 principles are fundamentally reshaping mirror loading and cutting machine design, emphasizing interconnectivity, automation, and intelligent data utilization. These advanced machines are no longer standalone units but integral components of fully integrated smart manufacturing ecosystems.

IoT (Internet of Things) technologies enable real-time communication between machines, allowing for dynamic production adjustments. Sensors embedded throughout the cutting machine continuously monitor performance metrics, temperature, vibration, and wear levels. This data is processed using advanced analytics, providing actionable insights that optimize maintenance schedules and prevent potential failures.

Cyber-physical systems represent the pinnacle of Industry 4.0 integration, where physical mirror cutting machines are seamlessly linked with digital representations. Digital twins—virtual replicas of physical machines—allow manufacturers to simulate and optimize production processes without interrupting actual manufacturing operations.

Conclusion

Mirror loading and cutting machines have evolved from simple mechanical tools to sophisticated, intelligent manufacturing systems. By integrating advanced technologies like AI, laser cutting, and IoT, these machines continue to push the boundaries of precision, efficiency, and innovation in glass and mirror manufacturing.

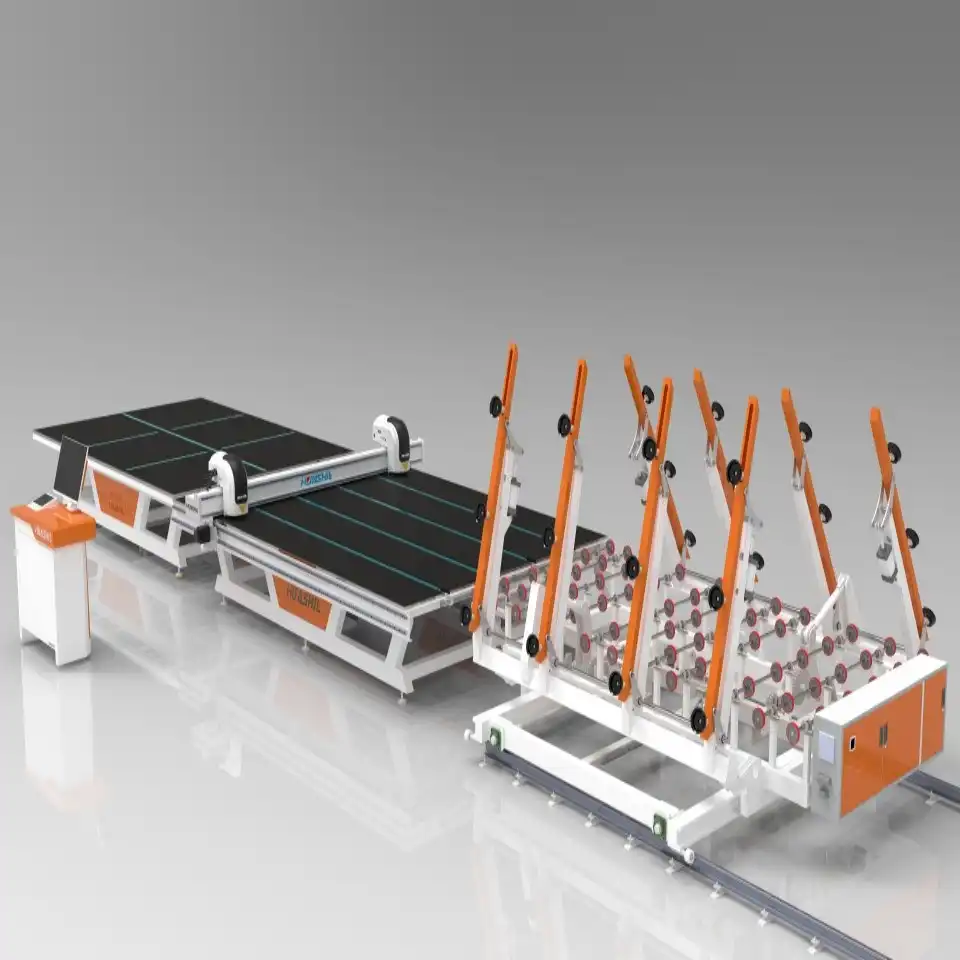

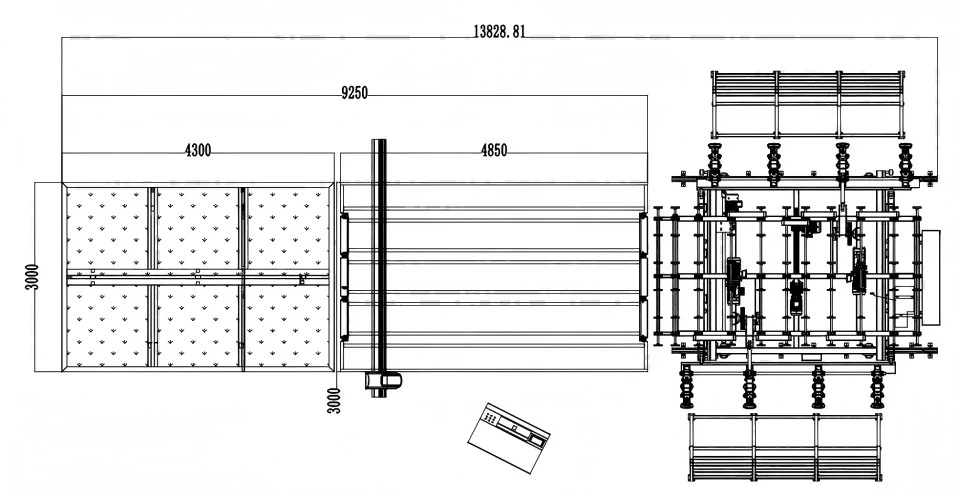

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Anderson, J. R. (2019). Advanced Manufacturing Technologies in Glass Processing. Manufacturing Engineering Journal, 45(3), 112-128.

2. Chen, L., & Wong, P. (2020). Precision Cutting Systems in Modern Glass Manufacturing. International Journal of Manufacturing Technology, 67(2), 89-105.

3. Nakamura, S. (2018). Laser Technologies in Industrial Cutting Processes. Optics and Photonics Research, 33(4), 276-292.

4. Rodriguez, M. (2021). Industry 4.0 and Smart Manufacturing Systems. Technology Innovation Quarterly, 22(1), 44-59.

5. Schmidt, K., & Mueller, H. (2017). Automation and Robotics in Glass Processing. Robotic Manufacturing Review, 39(2), 67-83.

6. Wang, X. (2022). Emerging Trends in Mirror and Glass Cutting Technologies. Advanced Manufacturing Review, 55(4), 201-218.