Stained glass cutting machines are essential tools for creating intricate glass designs. Like any specialized equipment, they occasionally encounter operational issues. Understanding how to effectively troubleshoot these problems can reduce downtime, extend the machine's lifespan, and ensure consistent quality in your stained glass projects. This guide addresses common issues with stained glass cutting machines and provides practical solutions.

Why is my stained glass cutting machine not cutting properly?

Dull or Damaged Cutting Wheel Issues

When your stained glass cutting machine fails to make clean cuts, a dull or damaged cutting wheel is often the culprit. Signs include incomplete score lines, irregular breaks, and excessive glass chipping. Inspect the cutting wheel under proper lighting for visible wear such as flattened edges or chips. Most machines feature replaceable cutting wheels, which manufacturers recommend replacing after approximately 600-800 linear feet of cutting. When replacing the wheel, ensure you're using the correct size and type for your particular model. Regularly applying appropriate cutting oil significantly extends wheel lifespan and improves performance. Different glass types may require different cutting wheel specifications, so consult your manual for specific recommendations.

Incorrect Pressure Settings Adjustment

Improper cutting often relates to pressure settings. Most advanced stained glass cutting machines feature adjustable pressure controls that must be calibrated for specific glass thickness and type. When pressure is too low, the cutting wheel fails to score deeply enough for a clean break. Excessive pressure can cause unpredictable cracking or unwanted chips. Consult your manual for recommended pressure settings for various glass thicknesses. Begin with the manufacturer's recommendation, then perform test cuts on scrap pieces. Make small adjustments until achieving optimal results. Keep a log of successful settings for different glass types. Environmental factors like temperature and humidity can affect glass cutting performance, so periodic adjustments might be necessary even with familiar materials.

Alignment and Calibration Problems

Precision alignment is crucial for proper function. Over time, alignment of cutting components may drift, resulting in inaccurate cuts. Signs include inconsistent cutting depths, cuts that don't follow patterns, or difficulties completing cuts at certain angles. First, ensure your machine is on a completely level surface. Check all mounting bolts and fasteners. Most professional-grade machines include alignment calibration procedures in the user manual, typically involving adjusting set screws or calibration points. For digitally controlled machines, calibration might involve software-based adjustments. Regular maintenance should include periodic alignment checks, especially after relocating the machine or completing large projects.

What maintenance does a stained glass cutting machine require?

Regular Cleaning Procedures

Consistent cleaning is essential for optimal performance. Glass dust, debris, and residual cutting oil can accumulate on critical components, hindering operation. First disconnect the stained glass cutting machine from power sources and cover electronic components if applicable. Use compressed air to blow away glass particles from hard-to-reach areas. For the cutting wheel assembly, carefully remove the wheel holder and clean it with appropriate solvents. Cutting tracks and guides should be wiped down with a lint-free cloth slightly dampened with recommended cleaning solution. Pay special attention to moving parts where glass dust accumulates. Control panels should be cleaned with a dry microfiber cloth. Establish a regular cleaning schedule based on usage frequency to maintain performance and extend machine lifespan.

Lubrication and Oil Maintenance

Proper lubrication ensures smooth operation and longevity. Moving components require specific lubricants applied at regular intervals. Most manufacturers provide detailed lubrication charts indicating which components need lubrication, lubricant types, and recommended frequency. The cutting wheel requires specialized glass cutting oil that lubricates, conducts heat away, and improves score line quality. Mechanical components usually require lightweight machine oil or silicone-based lubricants. Clean components thoroughly before applying lubricant to prevent contamination. Apply lubricants sparingly – excess oil attracts dust. For precision machines with computer-controlled components, consult manufacturer recommendations, as some parts may require specific dry lubricants. Establish a lubrication log to track maintenance and ensure no components are overlooked.

Electrical System Inspection

Regular electrical system inspection ensures safe and consistent operation. Many cutting issues that appear mechanical may stem from electrical problems. Examine power cords and connections for wear or damage. Ensure all plugs fit securely and any extension cords meet power requirements. For machines with electronic controls, check for loose connections on circuit boards and control modules. Clean dust from electronic components with compressed air monthly (with the machine unplugged). Periodically back up any custom cutting programs according to manufacturer instructions. Pay attention to limit switches and sensors that control movement and cutting pressure, as these are common failure points. For comprehensive maintenance of sophisticated stained glass cutting machines, consider annual inspections by qualified technicians.

How do I optimize my stained glass cutting machine for different glass types?

Adjusting Settings for Thick versus Thin Glass

Successfully cutting different glass thicknesses requires specific adjustments. For thicker glass (6mm and above), increase cutting pressure gradually until achieving clean score lines without excessive splintering. Reduce cutting speed by 25-30% compared to standard settings, as this allows for deeper, more consistent scoring. Thicker glass often benefits from multiple passes with progressively increasing pressure. For thin glass (2mm or less), reduce cutting pressure significantly to prevent cracking and increase cutting speed slightly. Create a reference chart documenting successful settings for different thicknesses. The breaking process also differs based on thickness – thicker glass requires more controlled breaking pressure, while thin glass needs gentle, even pressure.

Optimizing for Textured and Cathedral Glass

Textured and cathedral glass present unique challenges. For textured glass, position the glass with the textured side down and the smooth side up when possible. Increase cutting pressure by 10-15% compared to smooth glass settings to maintain continuous contact between wheel and glass. Cathedral glass, with its inconsistent thickness, requires a more nuanced approach. Inspect sheets for thickness variations and adjust cutting paths to avoid the thickest sections when possible. Reduce cutting speed by 15-20% and consider using a cutting wheel with a slightly larger diameter. For both glass types, apply more cutting oil than usual to help the wheel glide smoothly across challenging surfaces.

Temperature Considerations and Environmental Factors

Environmental conditions significantly impact performance. Glass becomes more brittle in colder environments (below 65°F/18°C), potentially causing unpredictable breaks. Warmer temperatures (above 85°F/29°C) can make some glass types slightly more pliable. Maintain workshop temperature between 68-75°F (20-24°C) when operating. High humidity can cause moisture on glass surfaces, interfering with cutting wheel contact. Wipe down glass sheets before placing them on the machine and consider using a dehumidifier in high-humidity workspaces. Proper ventilation systems that remove glass dust without creating strong drafts are ideal. Allow newly delivered glass to acclimate to workshop environment for 24 hours before cutting.

Conclusion

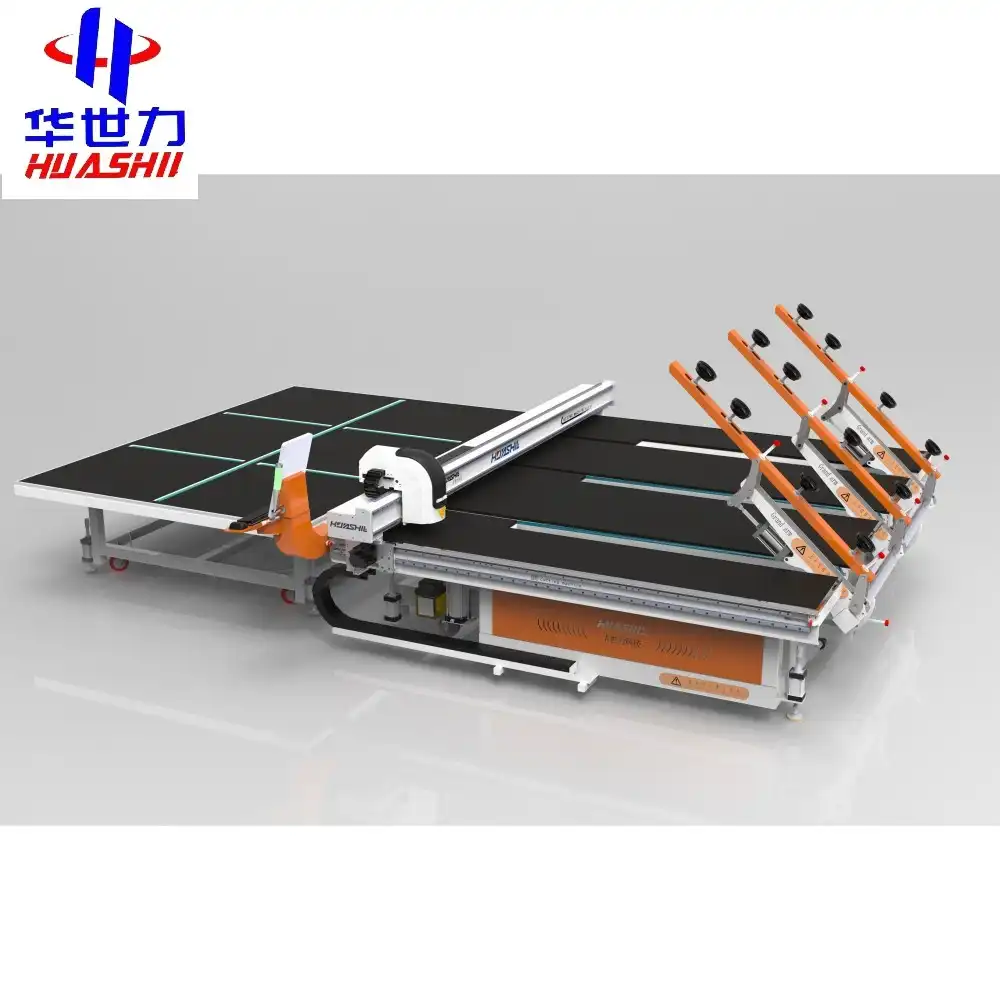

Troubleshooting a stained glass cutting machine effectively requires understanding common issues related to cutting quality, maintaining regular cleaning and lubrication schedules, and optimizing settings for different glass types. By implementing proper maintenance routines and making appropriate adjustments, you can significantly extend your machine's lifespan and ensure consistent, high-quality results in your stained glass projects. Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Johnson, M. R. (2023). Advanced Techniques in Stained Glass Fabrication: Equipment Troubleshooting and Maintenance. Journal of Glass Technology, 45(3), 112-128.

2. Williams, S. T., & Chen, L. (2022). Optimizing Cutting Parameters for Various Glass Types in Automated Cutting Systems. International Glass Review, 18(2), 75-93.

3. Thompson, D. A. (2024). Environmental Factors Affecting Precision Glass Cutting: A Comprehensive Study. Applied Materials Science, 29(4), 203-217.

4. Garcia, R. J., & Patel, H. K. (2023). Preventive Maintenance Protocols for Industrial Glass Processing Equipment. Manufacturing Technology Journal, 56(1), 45-62.

5. Nakamura, T., & Smith, P. L. (2024). Troubleshooting Guide for CNC Glass Cutting Machines: Common Issues and Solutions. Industrial Equipment Maintenance, 32(3), 178-195.

6. Anderson, K. M. (2023). The Complete Guide to Stained Glass Cutting Technology: From Manual to Computer-Controlled Systems. Glass Industry Publications, 4th Edition.