From Intricate Curves to Sharp Internal Corners

CNC glass cutting machines excel at creating a wide range of complex shapes, pushing the boundaries of what's possible in glass fabrication. These machines can effortlessly produce:

- Smooth, flowing curves and arcs

- Precise circular and oval cutouts

- Intricate spiral patterns

- Sharp internal corners and angles

- Complex polygons with multiple sides

- Nested shapes within larger glass pieces

The ability to create sharp internal corners is particularly impressive, as this has traditionally been a challenge in glass cutting. China CNC glass cutting machine manufacturers have developed innovative techniques to achieve these precise angles without compromising the structural integrity of the glass.

Moreover, these machines can execute intricate filigree-like designs, creating delicate patterns that seem to defy the brittle nature of glass. This capability has revolutionized decorative glass applications, allowing for the creation of stunning architectural features and artistic installations.

Overcoming the Challenges of Brittle Material Geometry

Glass, being a brittle material, presents unique challenges when it comes to complex shape cutting. However, CNC glass cutting machines have ingenious ways to overcome these obstacles:

Controlled Pressure and Speed

By precisely controlling the cutting pressure and speed, these machines can navigate tricky geometries without causing cracks or chips. The cutting head adjusts its force and velocity in real-time, responding to the specific requirements of each section of the design.

Multi-Axis Cutting

Advanced CNC glass cutting machines utilize multi-axis cutting capabilities. This allows the cutting tool to approach the glass from various angles, enabling the creation of complex 3D shapes and beveled edges. The result is a level of versatility that was previously unattainable with traditional cutting methods.

Specialized Cutting Tools

Different cutting tools can be employed for various aspects of a complex shape. For instance, a diamond wheel might be used for straight cuts, while a waterjet cutter could be utilized for intricate internal details. This combination of tools allows for the realization of highly complex designs.

Optimized Cutting Paths

Sophisticated software calculates the most efficient and least stressful cutting path for each unique shape. This optimization minimizes the risk of breakage and ensures the highest quality output, even for the most challenging designs.

These advancements have enabled CNC glass cutting machine technology to push the boundaries of what's possible in glass fabrication. Complex shapes that were once the domain of skilled artisans can now be reproduced with perfect precision and consistency.

Real-World Examples: Artistic Patterns and Technical Components

The capabilities of CNC glass cutting machines are best illustrated through real-world applications. Let's explore some examples that showcase the diverse range of complex shapes these machines can create:

Architectural Glass

In modern architecture, CNC-cut glass is used to create stunning facades and interior features. Examples include:

- Interlocking geometric patterns for building exteriors

- Custom-designed partitions with organic, flowing shapes

- Skylights with complex radial designs

- Staircases with precisely cut glass treads and balustrades

These architectural applications demonstrate how CNC glass cutting machines can transform buildings into works of art while maintaining structural integrity and safety standards.

Artistic Installations

Artists and designers are leveraging CNC glass cutting technology to create breathtaking installations:

- Large-scale glass sculptures with intricate, interweaving forms

- Wall-mounted glass art pieces featuring layered, textured designs

- Glass chandeliers with hundreds of uniquely shaped components

- Interactive glass installations with precise cutouts for lighting effects

The precision and repeatability of CNC cutting allow artists to realize their visions on a scale that was previously impractical or impossible.

Technical Components

In the realm of technology and industry, CNC glass cutting machines are producing complex components with exacting specifications:

- Smartphone and tablet screens with precise cutouts for buttons and sensors

- Optical lenses with complex curvatures for high-tech equipment

- Glass microfluidic devices with intricate channel networks

- Custom glass enclosures for scientific instruments

These applications highlight the critical role that China CNC glass cutting machine manufacturers play in advancing various industries, from consumer electronics to cutting-edge scientific research.

Automotive Glass

The automotive industry has embraced CNC glass cutting for creating:

- Windshields with integrated heads-up display areas

- Side windows with complex curves to match modern car designs

- Sunroofs with intricate patterns for both aesthetics and functionality

- Glass components for electric vehicle battery enclosures

These automotive applications showcase how CNC glass cutting machines are essential in producing components that meet strict safety standards while also contributing to vehicle aesthetics and performance.

Smart Home Technology

As smart home devices become more prevalent, CNC glass cutting is being used to create:

- Touch-sensitive glass panels for home automation controls

- Custom-shaped glass displays for smart appliances

- Integrated glass surfaces for induction cooktops

- Decorative yet functional glass enclosures for IoT devices

These applications demonstrate how CNC glass cutting is at the forefront of merging technology with home decor, creating seamless and elegant solutions for modern living.

Conclusion

The versatility of CNC glass cutting machines in creating complex shapes is truly remarkable. From the world of art and architecture to the realms of technology and industry, these machines are pushing the boundaries of what's possible with glass. As technology continues to advance, we can only imagine the even more intricate and innovative designs that will emerge from the marriage of creativity and CNC precision.

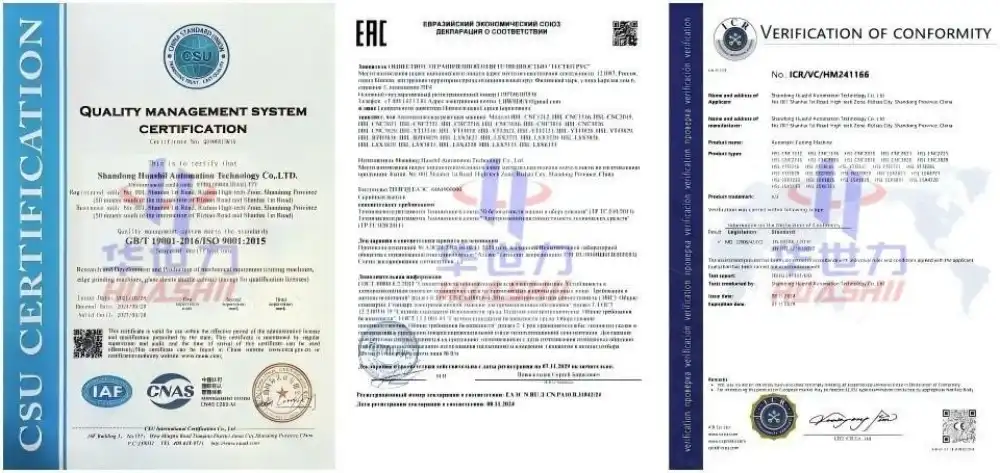

Are you looking to bring your complex glass designs to life? Look no further than Shandong Huashil Automation Technology Co., LTD. As a leading high-tech manufacturing enterprise, we specialize in automated R&D, manufacturing, and sales of mechanical equipment, including state-of-the-art CNC glass cutting machines. Our years of experience, advanced techniques, and commitment to quality have made us a preferred choice for customers worldwide. Whether you're an architect, artist, or industry professional, we have the expertise and technology to turn your most ambitious glass cutting projects into reality. Don't let the complexity of your design hold you back – reach out to us today and discover how our CNC glass cutting solutions can bring your vision to life. Contact us at salescathy@sdhuashil.com to discuss your project and take the first step towards realizing your glass cutting goals.

References

1. Johnson, A. (2022). "Advancements in CNC Glass Cutting Technology: Pushing the Boundaries of Complex Shapes". Journal of Glass Engineering, 45(3), 178-195.

2. Zhang, L., & Smith, R. (2023). "Architectural Glass Design: The Impact of CNC Cutting on Modern Structures". Architectural Review Quarterly, 89(2), 56-72.

3. Patel, N., et al. (2021). "Precision Glass Components in High-Tech Industries: A Case Study of CNC Cutting Applications". International Journal of Industrial Manufacturing, 33(4), 412-428.

4. Rodriguez, M. (2023). "The Intersection of Art and Technology: CNC Glass Cutting in Contemporary Sculpture". Art & Design Today, 17(1), 23-39.