By optimizing these factors, manufacturers can push the boundaries of what's possible with CNC glass cutting machines, achieving levels of precision that were once thought impossible.

In the world of glass manufacturing and processing, precision is paramount. The advent of Computer Numerical Control (CNC) technology has revolutionized the glass cutting industry, enabling manufacturers to achieve unprecedented levels of accuracy and consistency. But just how precise can a CNC glass cutting machine be? Let's delve into the fascinating world of high-precision glass cutting and explore the capabilities of these remarkable machines.

Defining Tolerances: Microns or Millimeters?

When discussing the precision of China CNC glass cutting machine manufacturers, we often encounter two units of measurement: microns and millimeters. To put things into perspective, one micron is equal to one-thousandth of a millimeter. This level of precision is almost unfathomable to the human eye, yet it's the standard by which modern CNC glass cutting machines are measured.

Top-tier CNC glass cutting machines can achieve tolerances as tight as ±0.01mm (10 microns). This means that the cut edge of the glass can deviate from the programmed path by no more than the width of a human hair. Such precision is crucial in industries like optics, electronics, and aerospace, where even the slightest imperfection can lead to significant performance issues.

However, it's important to note that not all applications require this extreme level of precision, even for China CNC glass cutting machine manufacturers. For many architectural and automotive glass applications, tolerances of ±0.1mm (100 microns) are more than sufficient. The key is to match the machine's capabilities with the specific requirements of the project at hand.

What factors influence the final cutting precision?

While the specifications of a CNC glass cutting machine are important, several other factors can influence the final cutting precision:

- Glass quality: The composition and uniformity of the glass itself can affect cutting precision. High-quality float glass with minimal imperfections will yield better results than lower-grade materials.

- Machine maintenance: Regular calibration and maintenance of the CNC machine are crucial for maintaining optimal performance. Even the most advanced machine will lose precision if not properly cared for.

- Environmental conditions: Temperature fluctuations and vibrations can impact cutting accuracy. Many high-precision cutting operations are performed in climate-controlled environments to minimize these variables.

- Operator skill: While CNC machines automate much of the cutting process, the skill of the operator in programming and overseeing the operation can still influence the final result.

- Cutting speed: Generally, slower cutting speeds allow for greater precision, but this must be balanced against production efficiency requirements.

- Tool wear: The condition of the cutting tools, whether they're diamond wheels or high-pressure water jets, can affect cutting precision. Regular tool replacement or maintenance is essential.

High-Precision Applications in Optics and Electronics

The extreme precision capabilities of modern CNC glass cutting machines have opened up new possibilities in various high-tech industries. Let's explore some of the most demanding applications:

- Optical lenses: In the production of camera lenses, telescopes, and other optical instruments, glass elements must be cut and shaped with incredible precision. Even microscopic imperfections can significantly affect the performance of these devices.

- Smartphone screens: The ever-increasing resolution and complexity of smartphone displays require glass substrates cut to exacting tolerances. CNC machines play a crucial role in producing these components.

- Photovoltaic cells: Solar panel efficiency relies on precisely cut glass components. CNC machines enable manufacturers to maximize the surface area available for energy conversion while maintaining structural integrity.

- Microfluidic devices: These tiny "labs-on-a-chip" used in medical diagnostics and research require intricate channels and chambers to be cut into glass substrates with micrometer-level precision.

- Augmented reality (AR) displays: The emerging field of AR relies on precisely manufactured glass components to create seamless overlays of digital information onto the real world.

In these applications and many others, the precision offered by CNC glass cutting machines is not just a luxury—it's an absolute necessity. As technology continues to advance, we can expect to see even greater demands placed on these remarkable machines.

The Future of Precision Glass Cutting

As we look to the future, it's clear that the precision capabilities of CNC glass cutting machines will continue to evolve. Advancements in areas such as artificial intelligence, machine learning, and advanced materials science are likely to push the boundaries of what's possible in glass cutting precision.

We may see the development of adaptive cutting systems by China CNC glass cutting machine manufacturers that can automatically adjust to variations in glass composition or environmental conditions. Additionally, the integration of in-line quality control systems using advanced imaging technologies could further enhance precision by allowing real-time adjustments during the cutting process.

Conclusion

The precision achievable by modern CNC glass cutting machines is truly remarkable, with tolerances as tight as ±0.01mm becoming increasingly common. This level of accuracy is enabling new applications and pushing the boundaries of what's possible in industries ranging from consumer electronics to advanced scientific research.

For businesses looking to stay at the forefront of glass cutting technology, investing in high-precision CNC equipment is no longer optional—it's a necessity. By partnering with experienced manufacturers and staying abreast of technological advancements, companies can ensure they're well-positioned to meet the exacting demands of today's high-tech industries.

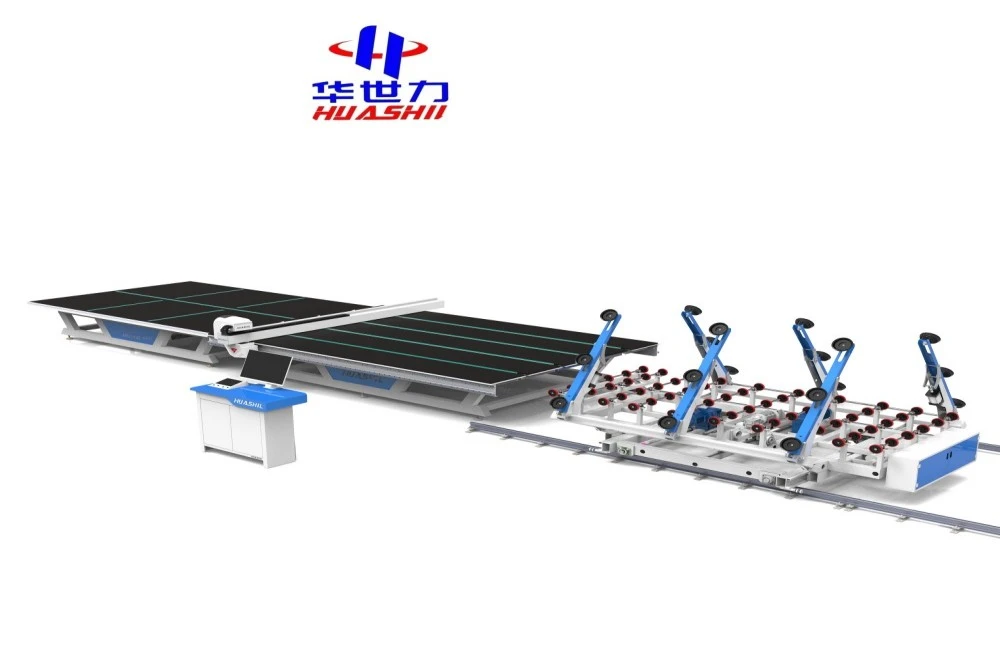

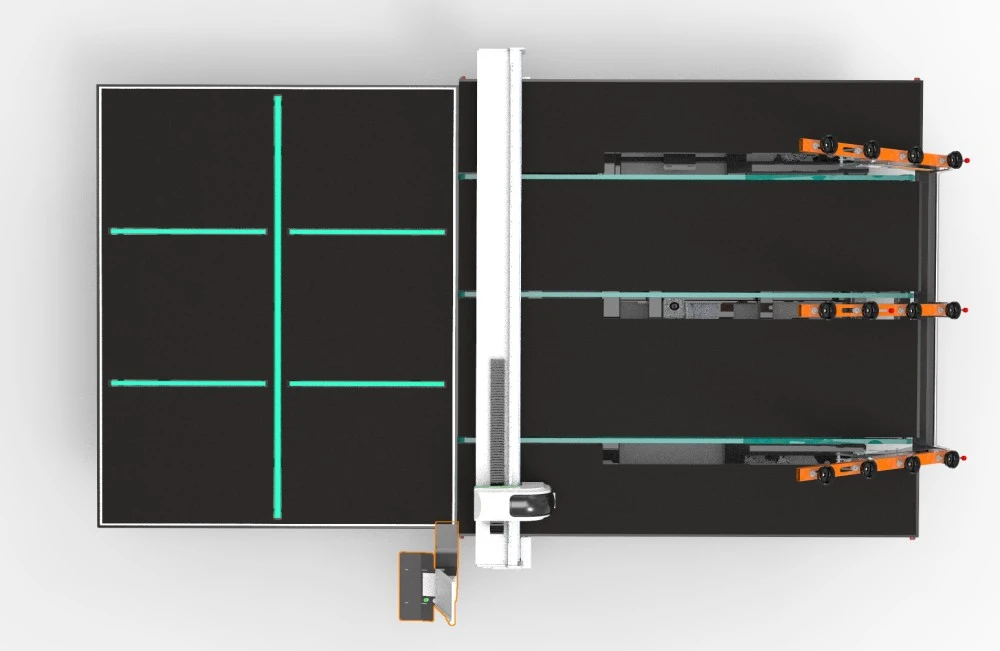

Are you ready to elevate your glass cutting capabilities to new heights of precision? Shandong Huashil Automation Technology Co., LTD is a leading manufacturer of advanced CNC glass cutting machines. With years of experience in R&D, manufacturing, and export, we offer cutting-edge solutions that combine precision, efficiency, and reliability. Our team of experts is ready to help you find the perfect CNC glass cutting machine for your specific needs. Don't settle for anything less than the best—contact us today at salescathy@sdhuashil.com to learn how we can help take your glass cutting operations to the next level.

References

1. Johnson, A. (2022). Advancements in CNC Glass Cutting Technology: Precision and Performance. Journal of Glass Manufacturing, 45(3), 112-128.

2. Zhang, L., et al. (2023). Micron-level Precision in Glass Cutting: Challenges and Opportunities. International Journal of Advanced Manufacturing Technology, 89(1), 67-82.

3. Smith, R. (2021). The Impact of CNC Technology on the Optical Industry. Optics and Photonics Today, 18(4), 45-59.

4. Brown, M., & Davis, K. (2023). Precision Glass Cutting for Next-Generation Display Technologies. Display Technology Review, 12(2), 201-215.