Glass cutting machines are essential equipment in the glass processing industry, enabling precise cuts for applications ranging from architectural glass to decorative pieces. Like any sophisticated equipment, these machines can experience operational issues affecting production quality and efficiency. Understanding common problems and their solutions is crucial for maintaining optimal performance and extending the lifespan of cutting machine for glass systems.

What causes glass cutting machines to produce inaccurate cuts?

Calibration and Alignment Issues

Calibration and alignment problems frequently affect cutting machine for glass accuracy. When machine components become misaligned due to vibration or regular use, cutting precision suffers. The cutting heads may not follow programmed paths exactly, causing deviations that affect the final product. Regular maintenance should include verifying alignment parameters, such as the squareness of the cutting bridge to the bed and the parallelism of the cutting head to the glass surface. Modern cutting machine for glass systems include built-in diagnostic tools that help identify calibration issues before they affect production. Manufacturers typically recommend quarterly calibration checks, with more frequent verification for high-volume operations or when working with glass types requiring exceptional precision.

Software and Control System Failures

Most contemporary cutting machine for glass systems rely on sophisticated software to translate designs into cutting instructions. This reliance introduces potential failure points. System crashes, communication errors, or corrupted cutting programs can lead to inaccurate cuts or operational failure. Common software issues include parameter storage failures, communication timeouts causing positioning errors, and interface glitches displaying incorrect information. Regular software updates are essential, as manufacturers frequently release patches addressing known issues. Maintaining proper backup procedures for cutting programs and machine settings minimizes downtime when software problems occur. Many cutting machine for glass providers now offer remote diagnostic capabilities, allowing technical support to analyze and sometimes resolve software issues without on-site visits.

Mechanical Wear and Component Degradation

Mechanical components of cutting machine for glass equipment endure significant stress during operation, leading to gradual wear affecting cutting accuracy. Critical components like linear bearings, drive belts, gears, and cutting wheels deteriorate with use, introducing inconsistency into the cutting process. The cutting wheel requires regular inspection as its condition directly impacts cut quality. Signs of mechanical wear include increased operational noise, visible cutting head vibration, inconsistent cutting pressure, or variations in cut quality. Implementing preventive maintenance with scheduled replacements of wear items can significantly reduce unexpected downtime. Modern cutting machine for glass systems often include sensors monitoring component conditions, allowing for planned maintenance rather than emergency repairs.

How can glass cutting machine breakdowns be prevented?

Implementing Proper Maintenance Protocols

Preventing breakdowns in cutting machine for glass equipment requires comprehensive maintenance protocols based on manufacturer recommendations but tailored to specific operational conditions. A well-designed maintenance schedule typically includes daily operator checks, weekly technical inspections, and quarterly comprehensive evaluations. Daily maintenance might involve cleaning cutting oil residue, checking fluid levels, and inspecting cutting wheels. Weekly maintenance could include lubricating moving parts, checking belt tensions, and testing safety systems. Effective maintenance programs maintain detailed logs of procedures, parts replaced, and issues discovered, creating a historical record that identifies recurring problems. Technicians should understand how the cutting machine for glass integrates into overall production flow to prioritize maintenance activities based on their potential impact.

Training Operators on Proper Machine Usage

Even advanced cutting machine for glass equipment can fail prematurely when operated incorrectly. Comprehensive operator training prevents breakdowns and ensures consistent output quality. Training should cover normal operation procedures, recognition of warning signs indicating developing problems, appropriate response to error messages, and basic troubleshooting. Operators should understand the relationship between cutting parameters like speed, pressure, and cutting oil flow, and how these factors influence both cut quality and component wear. Creating a culture where operators report subtle changes in machine performance prevents minor issues from developing into serious problems. Cross-training multiple operators ensures production continuity and provides valuable perspective sharing that often leads to process improvements.

Upgrading and Modernizing Aging Equipment

As cutting machine for glass technology advances, older equipment becomes increasingly prone to breakdowns. Strategic upgrading of components or systems can extend machinery life while improving reliability. Many manufacturers offer retrofit packages that bring modern control systems, improved cutting heads, or enhanced safety features to older machines. Common upgrades include transitioning from mechanical to digital controls, replacing traditional cutting heads with oscillating heads, implementing automatic glass handling systems, and adding optical recognition systems that detect glass defects before cutting. When considering upgrades, evaluate the return on investment through reduced maintenance costs, improved productivity, reduced material waste, and enhanced capabilities for processing specialized glass.

What factors affect the quality of cuts in glass cutting machines?

Glass Material Properties and Compatibility

Cut quality is significantly influenced by glass material properties. Different glass types exhibit varying hardness, brittleness, and internal stress characteristics affecting cutting behavior. Tempered glass cannot be cut after tempering, while laminated glass requires specialized approaches for different layers. When programming a cutting machine for glass, operators must consider glass composition, thickness uniformity, and any coatings. Advanced systems include material libraries that automatically adjust cutting parameters based on glass type. Temperature plays a crucial role; material that is too cold may resist scoring, while overly warm glass might produce excessive chipping. Manufacturers typically provide guidelines for optimum material temperature ranges and acclimation periods.

Environmental and Operational Conditions

The operating environment significantly impacts cut quality. Factors like ambient temperature, humidity, dust levels, and floor vibration influence precision and consistency. Temperature fluctuations cause thermal expansion or contraction of machine components, altering calibration. Humidity affects cutting oil properties and accelerates corrosion. Dust accumulation on guide rails introduces friction and wear degrading accuracy. Modern cutting machine for glass installations often include environmental control measures such as temperature-regulated enclosures and vibration-dampening foundations. Operational conditions also matter; running at maximum speed continuously stresses components more than moderate speeds, while inadequate warm-up periods can lead to inconsistent results.

Cutting Parameters and Tool Selection

Cutting parameters directly determine finished edge quality. Critical factors include cutting wheel pressure, cutting speed, scoring depth, and breaking bar settings, which must be optimized for each glass type and thickness. Insufficient pressure creates incomplete scores leading to irregular breaks, while excessive pressure accelerates wheel wear and causes chipping. The appropriate cutting wheel selection is equally important; wheels vary in diameter, edge angle, material composition, and coating. A cutting machine for glass typically requires different wheel types for various applications – for example, specific wheel angles perform better with different material thicknesses. Regular inspection and replacement of cutting wheels ensures consistent performance. Modern systems often include parameter optimization functions suggesting optimal settings based on material characteristics.

Conclusion

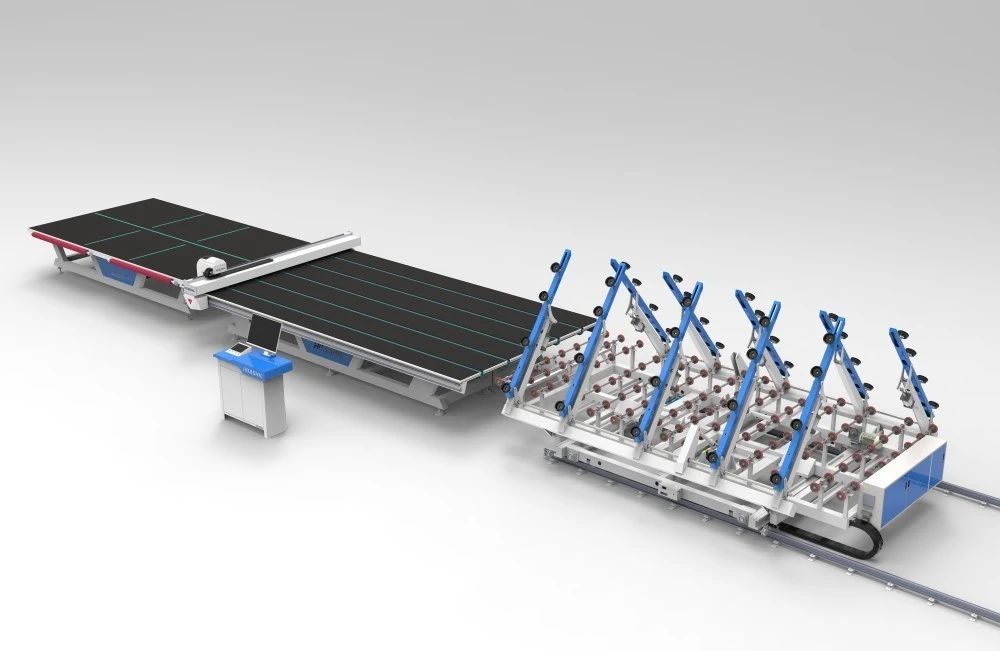

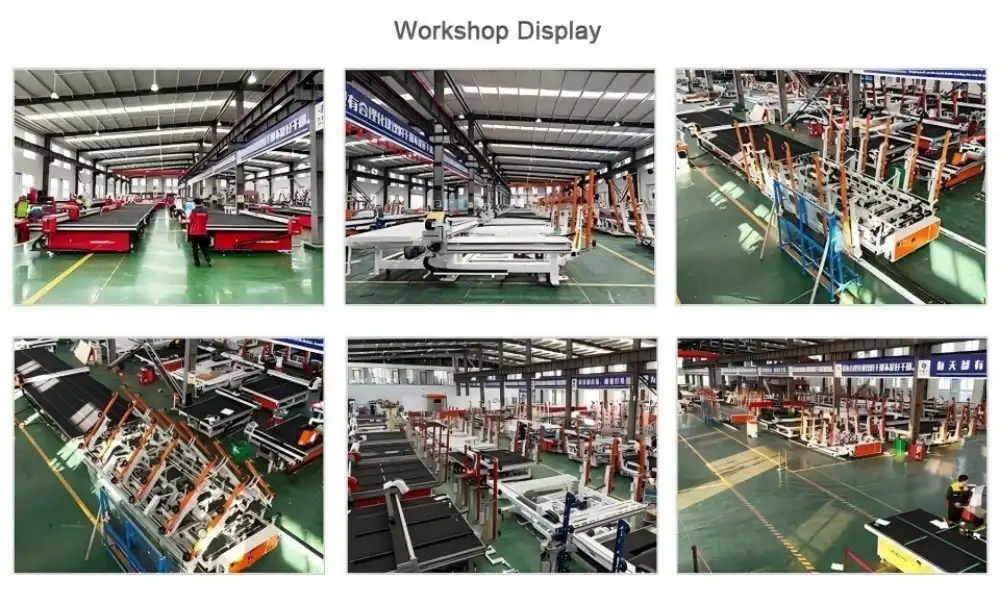

Understanding and addressing common problems with glass cutting machines is essential for maintaining productivity and product quality. From calibration issues and software failures to mechanical wear and environmental factors, proactive management of these challenges reduces downtime and waste. By implementing proper maintenance protocols, providing comprehensive operator training, and staying current with technological advancements, glass fabricators can maximize equipment performance and lifespan. Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Johnson, R.T. & Smith, P.K. (2023). Glass Processing Technology: Advancements and Challenges. Journal of Manufacturing Engineering, 45(3), 112-129.

2. Zhang, L., Wang, H., & Miller, J.C. (2022). Troubleshooting Common Issues in Automated Glass Cutting Systems. International Glass Review, 18(2), 78-94.

3. Patel, S.V. & Rodriguez, M.A. (2023). Maintenance Optimization for Industrial Glass Processing Equipment. Journal of Industrial Maintenance & Reliability, 29(4), 215-232.

4. Thompson, D.L. (2021). Quality Control in Automated Glass Fabrication: A Comprehensive Review. Journal of Materials Processing Technology, 312, 56-73.

5. Richardson, B.H. & Alvarez, T.J. (2022). Environmental Factors Affecting Precision in Glass Manufacturing. Advanced Materials Processing, 37(2), 145-163.

6. Chen, Y., Davis, K.L., & Wilson, E.B. (2023). Operator Training Protocols for Advanced Glass Processing Equipment. International Journal of Manufacturing Education, 51(3), 284-301.