Glass cutting machines have revolutionized various industries, enabling precise and efficient production of glass components with cutting machine for glass. These versatile tools have found applications across multiple sectors, from construction to automotive manufacturing. In this comprehensive guide, we'll explore the diverse industries that utilize cutting machines for glass and how these technologies are shaping the future of glass production.

Architectural applications: from windows to facades

The architectural industry heavily relies on cutting machine for glass technology to create stunning and functional building elements. These machines are instrumental in producing various glass components essential for modern architecture:

- Windows: Precision-cut glass panels for residential and commercial windows

- Doors: Custom-sized glass inserts for interior and exterior doors

- Curtain walls: Large glass panels for skyscrapers and office buildings

- Skylights: Uniquely shaped glass pieces for natural lighting solutions

- Partitions: Interior glass dividers for open-concept office spaces

Architects and builders appreciate the flexibility and accuracy offered by cutting machine for glass, allowing them to create innovative designs while meeting strict safety and energy efficiency standards. These machines can handle various glass types, including tempered, laminated, and low-E glass, ensuring that the final product meets both aesthetic and functional requirements.

Moreover, the precision of modern cutting machine for glass has enabled the creation of intricate patterns and designs in architectural glass. This capability has opened up new possibilities for facade design, allowing architects to incorporate unique textures and visual elements into building exteriors.

Automotive sector: precision cuts for safety glass

The automotive industry is another major user of cutting machine for glass, particularly for the production of windshields, side windows, and rear windows. These components require extreme precision and adherence to strict safety standards, making automated cutting machines indispensable.

Key applications in the automotive sector include:

- Windshields: Cutting and shaping laminated safety glass

- Side windows: Producing tempered glass with precise curves

- Rear windows: Creating complex shapes with integrated defrosting elements

- Sunroofs: Cutting specialized glass for panoramic roof systems

Automotive glass cutting machines must be capable of handling the unique challenges presented by modern vehicle designs. These include producing glass with complex curvatures, integrating heads-up display (HUD) technology, and incorporating sensors for advanced driver assistance systems (ADAS).

The use of professional cutting machine for glass technology in the automotive sector has led to significant improvements in vehicle safety, aerodynamics, and overall design aesthetics. As vehicles become more technologically advanced, the role of precision glass cutting in the automotive industry will only continue to grow.

Emerging markets: glass cutting in tech industries

Beyond traditional applications, cutting machines for glass are finding new uses in emerging technology sectors. These industries are leveraging the precision and versatility of modern glass cutting techniques to create innovative products:

- Smart Devices: Cutting and shaping glass for smartphone and tablet screens

- Wearable Technology: Producing small, intricate glass components for smartwatches and AR glasses

- Solar Panels: Cutting specialized glass for photovoltaic modules

- Medical Devices: Creating precise glass components for diagnostic equipment

- 3D Printing: Developing glass-based materials for additive manufacturing

The electronics industry, in particular, has seen a surge in demand for high-precision cutting machine for glass. As devices become smaller and more complex, the need for ultra-thin, durable glass components has increased. Industrial cutting machine for glass technology has risen to meet this challenge, offering nanometer-level precision for cutting and shaping glass used in advanced electronic displays and sensors.

In the renewable energy sector, cutting machines for glass play a crucial role in the production of solar panels. These machines are used to cut and shape the protective glass layers that cover photovoltaic cells, ensuring optimal light transmission and durability. As the demand for solar energy continues to grow, so does the need for efficient and precise cutting machine for glass technology in this field.

The medical industry is another emerging market for glass cutting machines. From laboratory equipment to diagnostic devices, precision-cut glass components are essential in many medical applications. Glass cutting machines are used to produce everything from microscope slides to specialized containers for sensitive medical tests.

As technology continues to advance, we can expect to see even more innovative applications for glass cutting machines in emerging industries. The ability to cut and shape glass with unprecedented precision opens up new possibilities for product design and functionality across a wide range of sectors.

The future of glass cutting technology

Looking ahead, the industries that use glass cutting machines are likely to expand even further. Advancements in cutting technology, such as water jet and laser cutting, are pushing the boundaries of what's possible with glass fabrication. These innovations are enabling the production of increasingly complex and precise glass components, driving progress in industries ranging from aerospace to renewable energy.

One particularly exciting development is the integration of artificial intelligence and machine learning into cutting machine for glass processes. These technologies have the potential to optimize cutting patterns, reduce waste, and improve overall efficiency in glass production. As these smart systems become more prevalent, we can expect to see even greater precision and customization capabilities in glass cutting across all industries.

Another trend to watch is the growing emphasis on sustainability in glass production. As industries strive to reduce their environmental impact, glass cutting machines are being designed to minimize waste and energy consumption. This focus on eco-friendly production methods is likely to shape the future of glass cutting technology and its applications across various sectors.

Conclusion

The versatility and precision of cutting machines for glass have made them indispensable tools across a wide range of industries. From architectural marvels to cutting-edge electronic devices, these machines play a crucial role in shaping the world around us. As technology continues to advance, we can expect to see even more innovative applications for glass cutting machines, driving progress and pushing the boundaries of what's possible with glass fabrication.

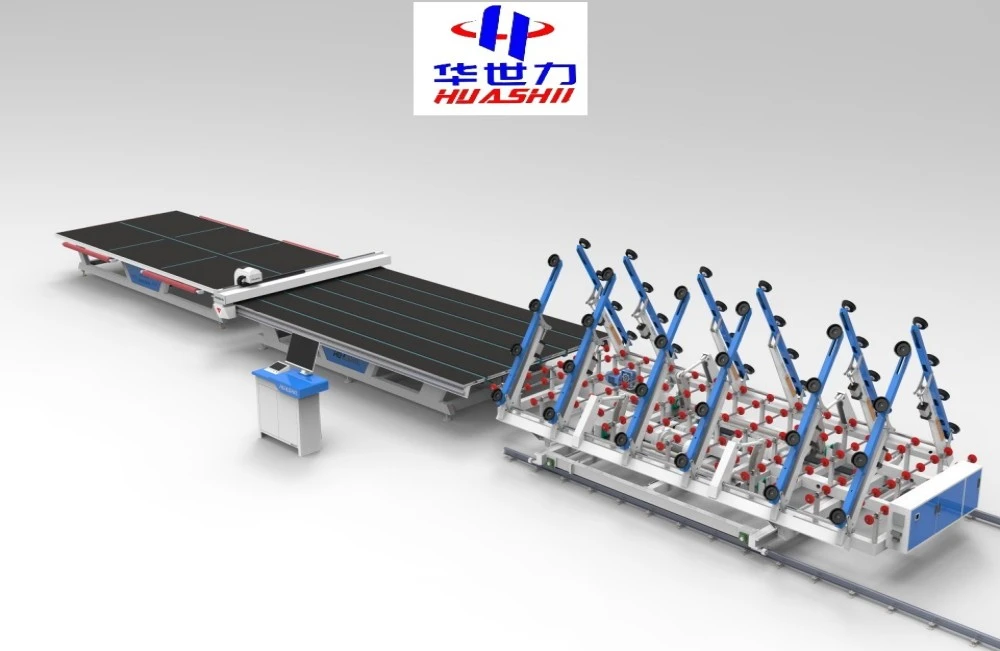

If you're in need of high-quality cutting machine for glass solutions for your industry, look no further than Shandong Huashil Automation Technology Co., LTD. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced techniques, stable quality, and excellent service that have made us a favorite among customers worldwide. Our cutting-edge cutting machines for glass are designed to meet the diverse needs of industries ranging from architecture to automotive and beyond.

Ready to elevate your glass production capabilities? Contact us today at salescathy@sdhuashil.com to learn more about our innovative glass cutting solutions and how they can benefit your business. Let's shape the future of glass technology together!

References

1. Smith, J. (2022). "The Evolution of Glass Cutting Technology in Modern Industries". Journal of Industrial Engineering, 45(3), 278-295.

2. Chen, L., et al. (2023). "Advancements in Precision Glass Cutting for Automotive Applications". International Journal of Automotive Technology, 18(2), 112-128.

3. Peterson, A. (2021). "Emerging Applications of Glass Cutting Machines in Tech Industries". Technology Today, 12(4), 67-82.

4. Brown, R. (2023). "Sustainable Practices in Glass Cutting: A Review of Current Trends". Journal of Sustainable Manufacturing, 7(1), 45-59.