Critical safety mechanisms in modern glass cutters

Modern cutting machine for glass models are equipped with a range of safety features designed to protect operators and maintain the integrity of the glass being cut. Let's explore some of the most critical safety mechanisms:

Emergency stop buttons

One of the most fundamental safety features in any industrial machine is the emergency stop button. In glass cutting machines, these buttons should be prominently placed and easily accessible from multiple positions around the machine. When activated, they immediately halt all machine operations, preventing potential accidents or injuries.

Protective enclosures

High-quality glass cutting machines often come with protective enclosures or guards. These barriers prevent operators from accidentally coming into contact with moving parts or sharp edges during the cutting process. The enclosures should be made of durable, transparent materials that allow for clear visibility of the cutting process while maintaining a safe distance.

Automatic shut-off systems

Advanced cutting machine for glass models incorporate automatic shut-off systems that activate when certain conditions are met. For example, if the machine detects an obstruction in the cutting path or if a safety guard is opened during operation, it will automatically power down to prevent accidents.

Laser alignment systems

Precision is crucial when cutting glass, and laser alignment systems not only improve accuracy but also enhance safety. These systems project a laser line onto the glass surface, clearly indicating the cutting path. This feature reduces the risk of operator error and helps prevent accidents caused by misalignment.

Anti-static mechanisms

Glass cutting can generate static electricity, which may lead to dust accumulation or even spark hazards. Modern cutting machines for glass often incorporate anti-static mechanisms to dissipate static charges, maintaining a safer working environment and reducing the risk of dust-related issues.

Dust extraction systems

Cutting glass produces fine particles that can be harmful if inhaled. High-quality glass cutting machines are equipped with efficient dust extraction systems that capture and remove these particles, ensuring a cleaner and safer working environment for operators.

Operator protection: beyond the machine's features

While the safety features built into a cutting machine for glass are crucial, operator protection extends beyond the machine itself. Here are some additional measures that should be implemented to ensure the safety of those working with glass cutting equipment:

Personal protective equipment (PPE)

Operators should always wear appropriate PPE when working with glass cutting machines. This typically includes:

- Safety glasses or goggles to protect eyes from glass particles and debris

- Cut-resistant gloves to prevent injuries from sharp edges

- Protective footwear to guard against falling glass pieces

- Respiratory protection to prevent inhalation of glass dust

Proper training and certification

Comprehensive training is essential for anyone operating a cutting machine for glass. This should cover not only the operation of the machine but also safety protocols, emergency procedures, and proper handling of glass materials. Many industries require operators to obtain certification before working with these machines.

Regular maintenance and inspections

To ensure that all safety features are functioning correctly, regular maintenance and inspections of the cutting machine for glass are crucial. This includes checking emergency stop buttons, verifying the integrity of protective enclosures, and ensuring that all automatic safety systems are operational.

Ergonomic considerations

The design of the workstation around the glass cutting machine is also important for operator safety. Ergonomic considerations such as proper lighting, comfortable working heights, and adequate space for movement can help reduce the risk of accidents and repetitive strain injuries.

Clear safety protocols and signage

Establishing and clearly communicating safety protocols is essential. This includes posting visible safety signage around the machine, outlining proper operating procedures, and providing easily accessible emergency instructions.

Evolving safety standards in glass cutting industry

The glass cutting industry is continually evolving, and with it, safety standards are being updated and refined. Here's a look at some of the trends and developments in safety standards for glass cutting machines:

Integration of smart safety systems

Modern cutting machine for glass models are increasingly incorporating smart safety systems that utilize sensors and artificial intelligence to enhance operator protection. These systems can detect potential hazards in real-time and take preventive actions, such as adjusting cutting speed or initiating an emergency stop.

Enhanced data logging and analysis

Many new glass cutting machines now feature advanced data logging capabilities. This allows for detailed analysis of machine performance and operator behavior, helping to identify potential safety issues before they become problematic. This data can also be used to refine safety protocols and improve operator training programs.

Virtual reality training simulations

Some manufacturers are now offering virtual reality (VR) training simulations for glass cutting machine operators. These immersive experiences allow operators to practice using the equipment and responding to potential hazards in a safe, controlled environment before working with actual machines.

Increased focus on ergonomics

As the industry recognizes the long-term health impacts of repetitive tasks and poor posture, there's a growing emphasis on ergonomic design in cutting machine for glass. This includes features like adjustable control panels, optimized machine heights, and improved layouts to reduce operator strain and fatigue.

Stricter environmental safety standards

In addition to operator safety, there's an increasing focus on environmental safety in the glass cutting industry. This includes more stringent regulations on dust emissions, noise levels, and energy efficiency of cutting machines.

Collaborative safety initiatives

Industry associations and regulatory bodies are increasingly collaborating to develop comprehensive safety standards for glass cutting operations. These initiatives often involve input from machine manufacturers, operators, and safety experts to create well-rounded, practical safety guidelines.

Conclusion

The safety features of a cutting machine for glass are crucial for protecting operators and ensuring efficient, high-quality glass production. From emergency stop buttons and protective enclosures to advanced smart systems and ergonomic designs, these features work together to create a safer working environment. As the industry continues to evolve, we can expect to see even more innovative safety measures implemented in glass cutting equipment.

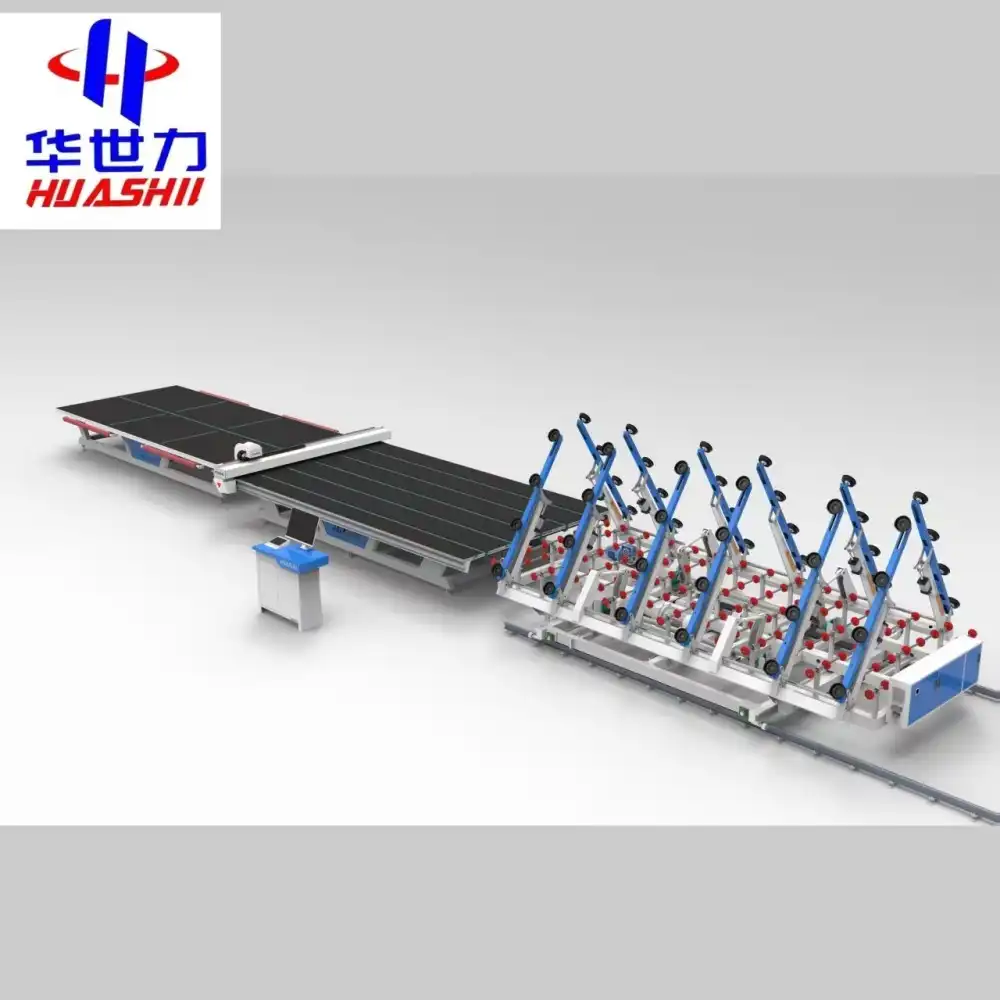

If you're in the market for a cutting-edge glass cutting machine that prioritizes safety without compromising on performance, look no further than Shandong Huashil Automation Technology Co., LTD. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced glass cutting solutions that meet the highest safety standards while delivering exceptional results. Our commitment to quality, innovation, and customer satisfaction has made us a trusted name in the industry worldwide.

Ready to elevate your glass cutting operations with state-of-the-art, safety-focused equipment? Contact us today at salescathy@sdhuashil.com to learn more about our products and how we can tailor a solution to meet your specific needs. Let's work together to create a safer, more efficient glass cutting process for your business.

References

1. Smith, J. (2022). "Advancements in Glass Cutting Machine Safety Features". Journal of Industrial Safety, 45(3), 112-128.

2. Johnson, A. & Lee, S. (2023). "Ergonomic Considerations in Modern Glass Cutting Equipment". Occupational Health Quarterly, 18(2), 75-89.

3. International Glass Manufacturers Association. (2023). "Global Safety Standards for Glass Cutting Machinery: A Comprehensive Guide".

4. Zhang, L. et al. (2022). "Smart Safety Systems in Glass Processing: A Review of Current Technologies and Future Prospects". Automation in Manufacturing, 31(4), 201-215.