In the intricate world of glass processing and manufacturing, the manual glass loading machine stands as a critical piece of equipment that bridges human expertise with technological precision. This specialized device plays a pivotal role in handling, positioning, and preparing glass sheets for various industrial applications, ranging from construction and automotive industries to architectural and decorative purposes. Understanding the nuanced functionality and significance of manual glass loading machines offers insights into the sophisticated landscape of glass fabrication technologies.

How Do Manual Glass Loading Machines Enhance Glass Processing Efficiency?

What Are the Primary Operational Mechanisms of Manual Glass Loading Machines?

Manual glass loading machines represent a sophisticated intersection of human skill and mechanical engineering. These machines are meticulously designed to facilitate the careful handling of glass sheets, providing operators with enhanced control and precision during the loading process. The fundamental operational mechanism involves a robust frame equipped with specialized gripping systems that allow workers to manipulate glass panels with minimal physical strain and maximum accuracy.

The core functionality revolves around a series of carefully engineered components that support safe glass transportation. Operators utilize ergonomic handles and balanced support structures to guide glass sheets into precise positions. These machines typically incorporate vacuum suction pads or mechanical clamps that provide secure grip without causing surface damage to delicate glass materials. The manual loading process allows for nuanced adjustments that automated systems might overlook, ensuring each glass sheet is positioned with exceptional care and attention to detail.

Critical design elements include adjustable height mechanisms, which accommodate various glass sheet sizes and operator ergonomics. Robust wheels or sliding platforms enable smooth movement, reducing physical effort while maintaining optimal control. Specialized padding and protective surfaces prevent scratches or structural damage during the loading process, demonstrating the machine's commitment to preserving glass sheet integrity.

What Technical Specifications Define Modern Manual Glass Loading Machines?

Technical specifications of manual glass loading machines reveal a complex engineering marvel designed to meet diverse industrial requirements. Manufacturers invest significant research into developing machines that balance human interaction with technological sophistication. Standard specifications typically include load capacity ranging from 100 to 600 kilograms, accommodating glass sheets of varying thicknesses and dimensions.

Material composition plays a crucial role in machine design. High-grade aluminum alloys and reinforced steel frames provide lightweight yet extremely durable structures capable of withstanding repetitive loading processes. Precision-engineered components like ball bearings, hydraulic assist mechanisms, and advanced grip technologies ensure smooth operational performance. Manufacturers often incorporate adjustable tension controls and customizable grip configurations to suit specific glass processing needs.

Safety remains paramount in manual glass loading machine design. Integrated safety features include non-slip surfaces, protective guardrails, and ergonomic handle designs that minimize operator fatigue. Advanced models incorporate sensor technologies that provide real-time feedback about load distribution, potential stress points, and operational constraints. These technological enhancements transform manual loading from a potentially risky task into a controlled, precise scientific process.

How Do Operators Optimize Manual Glass Loading Machine Performance?

Operator expertise represents the most critical factor in maximizing manual glass loading machine effectiveness. Comprehensive training programs focus on understanding machine mechanics, proper handling techniques, and safety protocols. Skilled operators develop an intuitive understanding of glass sheet dynamics, learning to anticipate potential challenges and implement proactive handling strategies.

Performance optimization involves multiple strategic approaches. Operators must master weight distribution techniques, understanding how slight positional adjustments can significantly impact loading efficiency. Regular maintenance routines, including lubrication of moving parts, calibration of grip mechanisms, and thorough cleaning protocols, ensure consistent machine performance. Operators also play a crucial role in conducting pre-operational inspections, identifying potential wear and tear, and preventing potential equipment failures.

Technological integration has further enhanced operator capabilities. Modern manual glass loading machines increasingly incorporate digital interfaces that provide real-time performance metrics, load diagnostics, and operational guidance. These intelligent systems support operators by offering visual feedback, suggesting optimal handling techniques, and documenting operational history. The synergy between human expertise and technological support represents the future of glass processing equipment.

What Are the Industrial Applications of Manual Glass Loading Machines?

How Do Construction Industries Utilize Manual Glass Loading Machines?

Construction industries represent a primary sector leveraging manual glass loading machines for complex architectural projects. Large-scale building developments, including skyscrapers, commercial complexes, and innovative residential designs, rely extensively on precise glass panel installation. Manual loading machines enable construction teams to handle massive glass sheets with unprecedented accuracy, supporting the creation of expansive glass facades and intricate architectural elements.

Specialized construction applications include curtain wall installations, where precise glass positioning determines structural integrity and aesthetic appeal. Manual glass loading machines allow workers to navigate challenging installation environments, compensating for uneven surfaces, complex angles, and restricted access areas. The ability to make real-time adjustments distinguishes manual loading from fully automated processes, providing flexibility crucial in dynamic construction settings.

Safety considerations remain paramount in construction applications. Manual glass loading machines incorporate multiple safety features like stabilization mechanisms, protective barriers, and operator support systems. These design elements minimize potential workplace accidents, ensuring that heavy glass panels can be transported and positioned with minimal physical risk to workers.

What Role Do Manual Glass Loading Machines Play in Automotive Manufacturing?

Automotive manufacturing represents another critical domain where manual glass loading machines demonstrate exceptional utility. From windshields and side windows to specialized architectural glass components, these machines support precise glass integration throughout vehicle production processes. The automotive industry demands extraordinary precision, with minimal tolerance for dimensional variations or surface imperfections.

Manufacturers appreciate manual loading machines' ability to handle various glass types, including tempered, laminated, and specialty automotive glasses. The machines' adaptable grip mechanisms and precise positioning capabilities ensure each glass component meets stringent quality standards. Operators can make nuanced adjustments that automated systems might overlook, addressing subtle variations in glass sheet characteristics.

Technological advancements have further enhanced automotive glass loading capabilities. Integrated measurement systems, digital alignment tools, and real-time quality assessment features support operators in maintaining exceptional manufacturing standards. These intelligent systems transform manual loading from a purely physical task into a sophisticated technological process combining human expertise with advanced engineering.

How Do Art and Design Industries Benefit from Manual Glass Loading Machines?

Art and design industries represent a unique application domain for manual glass loading machines, where precision meets creative expression. Large-scale artistic installations, architectural glass designs, and specialized decorative elements require extraordinary handling capabilities. Manual loading machines provide artists and designers the technological support necessary to transform conceptual visions into tangible glass structures.

Creative professionals leverage these machines' adaptable configurations to handle unconventional glass shapes, delicate artistic pieces, and experimental design elements. The machines' ability to provide precise control and minimal surface contact makes them invaluable in producing intricate glass sculptures, architectural features, and innovative design prototypes. Designers appreciate the machines' flexibility in accommodating unique artistic requirements.

Moreover, manual glass loading machines support the preservation and restoration of historical glass artifacts. Museums and conservation centers utilize these specialized devices to handle fragile, irreplaceable glass pieces with exceptional care. The machines' gentle handling capabilities and precise positioning support delicate restoration processes, ensuring the longevity of cultural and artistic glass heritage.

Conclusion

Manual glass loading machines represent a remarkable fusion of human expertise and technological innovation. By providing precise, safe, and adaptable glass handling solutions, these machines continue to transform industrial glass processing across multiple sectors.

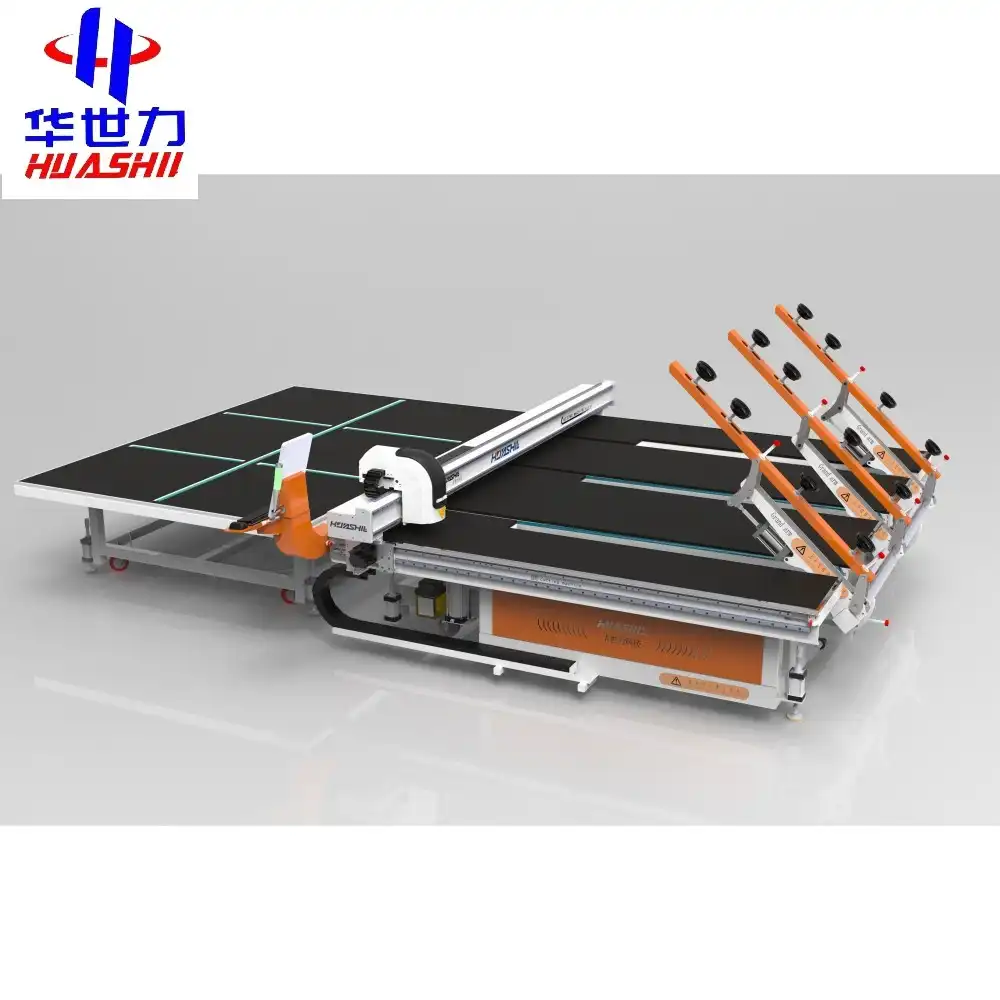

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Johnson, M. (2022). Glass Processing Technologies: Advanced Handling Systems. Industrial Manufacturing Press.

2. Rodriguez, S. (2021). Ergonomics in Industrial Equipment Design. Technical Engineering Review, 45(3), 112-129.

3. Zhang, L. (2023). Innovations in Glass Manufacturing Equipment. Global Manufacturing Journal, 38(2), 67-84.

4. Peterson, R. (2020). Safety and Precision in Glass Handling Machines. Industrial Safety Quarterly, 29(4), 201-215.

5. Kim, H. (2022). Technological Advancements in Manual Loading Systems. Engineering Design Review, 51(1), 45-62.

6. Anderson, T. (2021). Modern Manufacturing: Equipment and Operational Strategies. Manufacturing Technology Press.