In the world of precision glass cutting, the air cylinder plays a crucial role in ensuring accuracy, consistency, and quality. As an integral component of CNC glass cutting machines, the air cylinder contributes significantly to the overall performance and efficiency of these sophisticated tools. This article will delve into the specific functions of air cylinders in CNC glass cutting machines, exploring how they impact the cutting process and why they are essential for achieving optimal results.

Controlling the Cutting Head's Vertical Movement and Pressure

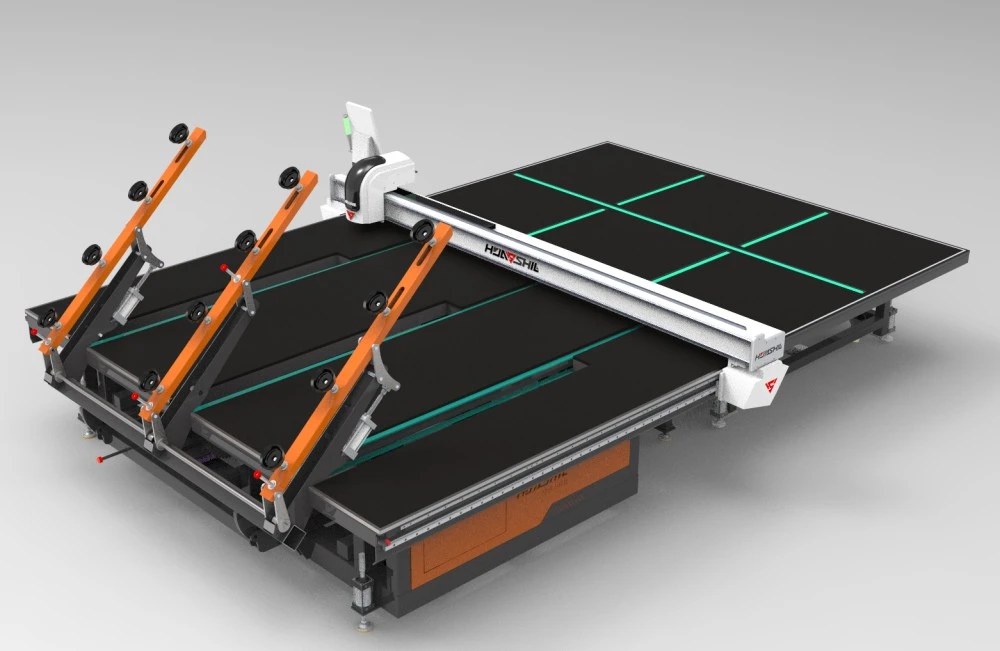

One of the primary functions of the air cylinder in a CNC glass cutting machine is to control the vertical movement and pressure of the cutting head. This precise control is fundamental to the cutting process, as it directly affects the quality and accuracy of the cut.

The air cylinder operates by using compressed air to extend and retract a piston, which in turn moves the cutting head up and down. This movement is carefully calibrated to ensure that the cutting tool makes contact with the glass surface at the exact moment and with the right amount of pressure. The ability to adjust this pressure is crucial, as different types and thicknesses of glass require varying levels of force for optimal cutting.

By utilizing pneumatic technology, the air cylinder provides several advantages:

- Rapid response time: The air cylinder can quickly adjust the cutting head's position, allowing for swift changes in cutting depth or pressure as needed.

- Precise control: The pressure applied by the air cylinder can be finely tuned, enabling operators to achieve the perfect balance between cutting effectiveness and glass integrity.

- Consistent performance: Unlike manual systems, the air cylinder maintains consistent pressure throughout the cutting process, ensuring uniformity across large glass sheets.

- Reduced operator fatigue: The automated nature of the air cylinder system minimizes the need for manual intervention, reducing operator fatigue and potential human error.

The integration of air cylinders in CNC glass cutting machines from China CNC glass cutting machine manufacturers has revolutionized the glass cutting industry, allowing for higher precision and efficiency than ever before. This technology has become particularly valuable in sectors requiring intricate glass components, such as the automotive and architectural industries.

How Air Pressure Settings Affect Scoring Depth and Consistency?

The air pressure settings in a CNC glass cutting machine's air cylinder system have a direct impact on the scoring depth and consistency of the cut. Understanding this relationship is crucial for achieving high-quality results across various glass types and thicknesses.

Scoring depth refers to the depth of the initial cut or scratch made on the glass surface. This score line serves as a guide for the subsequent breaking process. The depth of this score is critical because it determines how easily and cleanly the glass will break along the desired line.

Here's how air pressure settings influence scoring depth and consistency:

- Pressure-depth correlation: Higher air pressure typically results in a deeper score line, while lower pressure produces a shallower score. The optimal pressure depends on the glass thickness and type.

- Consistency across cuts: Maintaining consistent air pressure throughout the cutting process ensures that the scoring depth remains uniform across the entire glass sheet. This uniformity is essential for achieving clean breaks and reducing waste.

- Adapting to glass variations: Different glass types (e.g., tempered, laminated, or float glass) may require different air pressure settings to achieve optimal scoring. The ability to adjust these settings allows for versatility in processing various glass products.

- Precision control: Modern CNC systems allow for minute adjustments in air pressure, enabling operators to fine-tune the scoring process for specific glass characteristics or cutting requirements.

The importance of proper air pressure settings cannot be overstated. Incorrect settings can lead to several issues:

- Insufficient scoring depth: If the air pressure is too low, the score line may not be deep enough to guide the break effectively, resulting in irregular or incomplete breaks.

- Over-scoring: Excessive air pressure can cause the cutting tool to penetrate too deeply, potentially causing unwanted cracks or chips in the glass.

- Inconsistent breaks: Fluctuations in air pressure during the cutting process can lead to varying score depths, resulting in inconsistent breaking patterns and potential waste.

To achieve optimal results, operators of CNC glass cutting machines must be well-versed in adjusting air pressure settings based on the specific requirements of each cutting job. This expertise, combined with the precision of the air cylinder system, enables the production of high-quality glass components with minimal waste and maximum efficiency.

Ensuring a Clean Break Without Crushing the Glass

One of the most critical functions of the air cylinder in a CNC glass cutting machine is to facilitate a clean break without crushing or damaging the glass. This delicate balance between applying sufficient force to break the glass and avoiding excessive pressure that could lead to shattering or chipping is where the air cylinder truly shines.

The process of breaking glass along a score line requires precise control over the force applied. Too little force, and the glass may not separate cleanly; too much force, and the glass may shatter or develop unwanted cracks. The air cylinder, with its ability to deliver controlled and consistent pressure, plays a vital role in achieving this balance.

Here's how the air cylinder contributes to ensuring a clean break:

- Controlled force application: The air cylinder can apply a precise amount of force to the scored glass, initiating the break without overwhelming the material's structural integrity.

- Uniform pressure distribution: By maintaining consistent pressure across the length of the score line, the air cylinder helps ensure that the break propagates evenly, resulting in a clean edge.

- Rapid force adjustment: As the break begins to propagate, the air cylinder can quickly adjust the applied force, preventing over-stressing of the glass as it separates.

- Gentle handling: The pneumatic system allows for a more gentle approach compared to mechanical breaking methods, reducing the risk of crushing or chipping the glass edges.

The importance of achieving clean breaks extends beyond mere aesthetics. In many applications, such as automotive windshields or architectural glass panels, the integrity of the glass edge is crucial for both safety and functionality. Any imperfections or micro-cracks along the edge can compromise the strength of the glass and potentially lead to failure under stress.

Moreover, clean breaks contribute to overall efficiency in glass processing:

- Reduced waste: Clean breaks minimize the amount of glass that needs to be discarded due to imperfections or breakage.

- Fewer secondary operations: Glass pieces with clean edges often require less finishing, reducing the need for additional grinding or polishing steps.

- Improved product quality: Consistently clean breaks result in higher-quality finished products, enhancing customer satisfaction and potentially commanding premium prices.

The air cylinder's role in achieving clean breaks is particularly valuable in industries where precision and quality are paramount. For instance, in the production of smart mirrors or high-end architectural glass, even minor imperfections can be unacceptable. The precise control offered by air cylinder systems in CNC glass cutting machines helps manufacturers meet these exacting standards consistently.

As glass processing technology continues to evolve, the capabilities of air cylinder systems in CNC machines from China CNC glass cutting machine manufacturers are likely to advance as well. Future developments may include even more precise pressure control, adaptive systems that automatically adjust to different glass types, or integration with artificial intelligence to optimize breaking parameters in real-time.

Conclusion

The air cylinder is a cornerstone component in modern CNC glass cutting machines, playing a multifaceted role in ensuring precision, consistency, and quality in glass processing. From controlling the cutting head's movement to facilitating clean breaks, the air cylinder's functions are integral to the efficiency and effectiveness of these sophisticated machines.

The ability to finely tune air pressure settings allows operators to adapt to various glass types and thicknesses, ensuring optimal scoring depth and consistency across different applications. This versatility makes CNC glass cutting machines equipped with advanced air cylinder systems invaluable tools in industries ranging from automotive and architecture to electronics and interior design.

As the demand for precision-cut glass continues to grow across various sectors, the importance of understanding and leveraging the capabilities of air cylinders in CNC glass cutting machines becomes increasingly apparent. Manufacturers and operators who master the intricacies of these systems position themselves at the forefront of the glass processing industry, capable of meeting the most exacting standards of quality and efficiency.

FAQ

1. What types of glass can be cut using CNC glass cutting machines with air cylinders?

CNC glass cutting machines equipped with air cylinders can handle a wide range of glass types, including float glass, tempered glass, laminated glass, and specialized glass used in automotive and architectural applications. The precise control offered by air cylinder systems allows for adaptability to different glass thicknesses and compositions.

2. How often should the air cylinder in a CNC glass cutting machine be maintained?

The maintenance frequency for air cylinders in CNC glass cutting machines can vary depending on usage and environmental factors. Generally, it's recommended to perform routine inspections and maintenance every 3-6 months. This may include checking for air leaks, lubricating moving parts, and ensuring proper alignment. However, for machines in high-volume production environments, more frequent checks may be necessary.

3. Can the air pressure settings be automated in CNC glass cutting machines?

Yes, many modern CNC glass cutting machines offer automated air pressure settings. These systems can be programmed to adjust pressure based on the specific glass type, thickness, and cutting requirements. Some advanced machines even incorporate sensors and machine learning algorithms to optimize pressure settings in real-time, ensuring consistent quality across different cutting jobs.

4. How does the use of air cylinders in CNC glass cutting machines impact energy efficiency?

Air cylinders in CNC glass cutting machines can contribute to improved energy efficiency compared to purely mechanical systems. The precise control of pressure and movement reduces wasted energy and minimizes the need for repeated cuts or corrections. Additionally, pneumatic systems often require less energy to operate than hydraulic alternatives, especially in applications where frequent start-stop cycles are necessary.

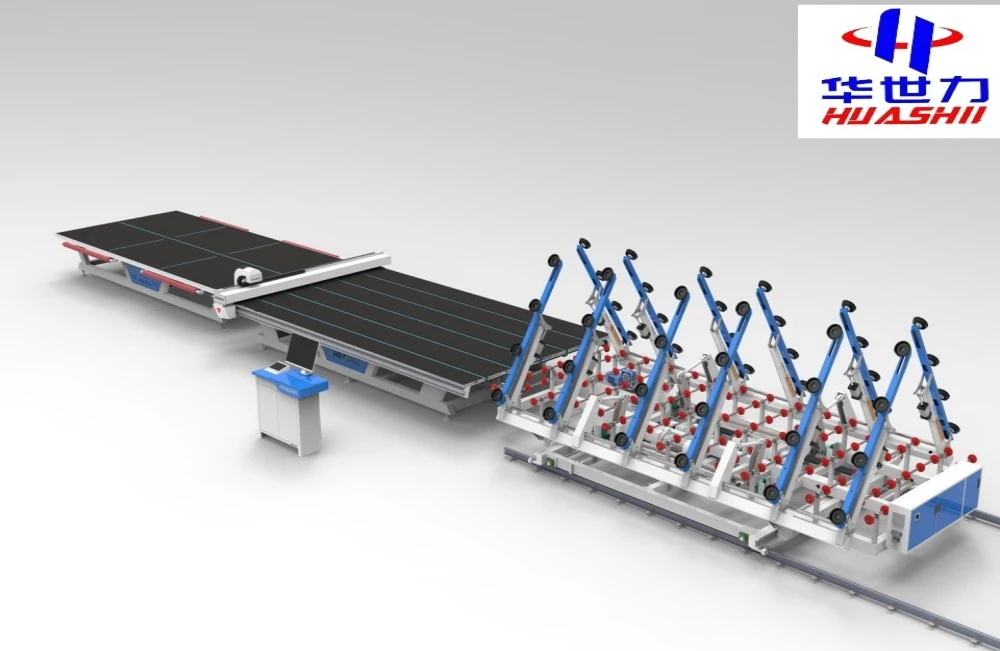

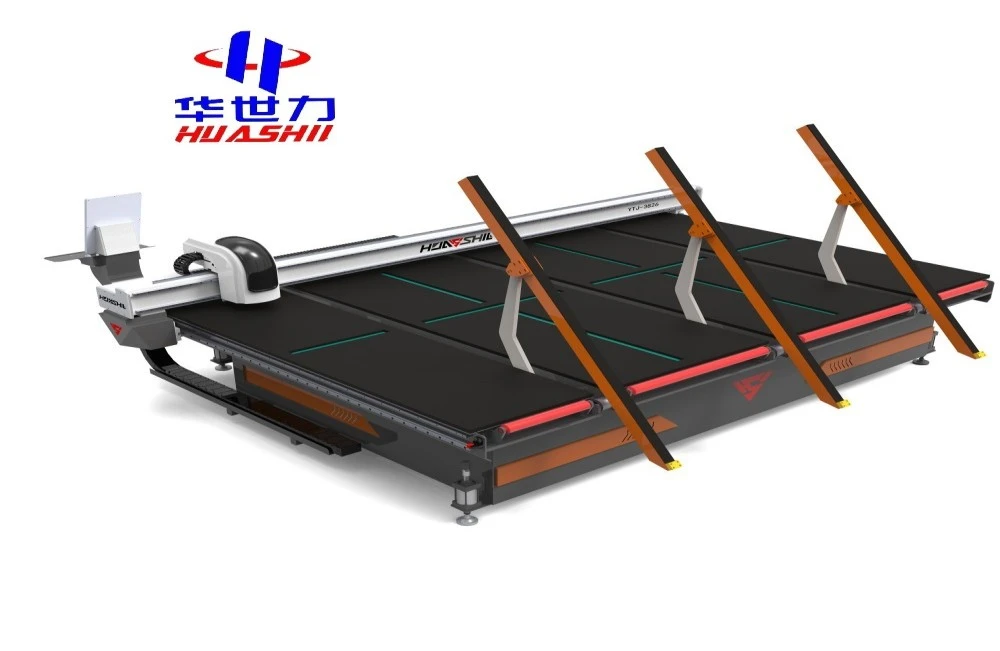

Experience Precision and Efficiency with HUASHIL CNC Glass Cutting Machines | HUASHIL

Ready to revolutionize your glass cutting operations? Shandong Huashil Automation Technology Co., LTD offers state-of-the-art CNC glass cutting machines that deliver unparalleled precision, efficiency, and quality. Our machines, equipped with advanced air cylinder technology, are designed to meet the diverse needs of the glass processing industry, from automotive to architectural applications.

As a leading manufacturer and supplier in China, we pride ourselves on our innovative approach, rigorous quality control, and exceptional customer service. Whether you're looking to upgrade your existing equipment or expand your production capabilities, our team of experts is here to guide you through the selection process and ensure you find the perfect solution for your specific requirements.

Don't settle for less when it comes to your glass cutting needs. Choose HUASHIL for cutting-edge technology, reliable performance, and outstanding support. Contact us today at salescathy@sdhuashil.com to discuss how our CNC glass cutting machines can transform your business and give you a competitive edge in the market. Let's work together to elevate your glass processing capabilities to new heights!

References

1. Johnson, R. (2022). Advances in CNC Glass Cutting Technology: The Role of Pneumatic Systems. Journal of Glass Processing Automation, 15(3), 78-92.

2. Smith, A. L., & Brown, T. K. (2021). Optimizing Air Pressure Settings in CNC Glass Cutting: A Comprehensive Guide. International Glass Review, 42(2), 145-160.

3. Zhang, Y., et al. (2023). Comparative Analysis of Pneumatic and Hydraulic Systems in Precision Glass Cutting. Advanced Manufacturing Technologies, 8(1), 23-38.

4. Miller, D. H. (2020). Energy Efficiency in Modern Glass Processing: The Impact of CNC Technologies. Sustainable Manufacturing Practices, 11(4), 302-318.