In the world of precision glass manufacturing, the type of controller used in a CNC glass cutting machine plays a crucial role in determining the efficiency, accuracy, and overall performance of the equipment. As technology continues to advance, the controllers used in these machines have become increasingly sophisticated, offering a wide range of features and capabilities. In this article, we'll explore the different types of controllers used in CNC glass cutting machines and their key characteristics.

PC-Based vs. Dedicated CNC Controllers: A Comparison

When it comes to CNC glass cutting machines, there are two main types of controllers: PC-based controllers and dedicated CNC controllers. Each has its own set of advantages and drawbacks, making them suitable for different applications and production environments.

PC-based controllers, as the name suggests, utilize a standard personal computer as the core of the control system. These controllers offer several benefits:

- Flexibility: PC-based controllers can be easily updated with new software and features, allowing for greater adaptability to changing production needs.

- Familiarity: Many operators are already familiar with PC interfaces, reducing the learning curve.

- Cost-effectiveness: Generally, PC-based systems are less expensive than dedicated CNC controllers.

- Integration: They can easily integrate with other software systems used in the production process.

However, PC-based controllers also have some limitations:

- Reliability: PCs are more susceptible to crashes and viruses, which can lead to downtime.

- Processing power: They may struggle with complex, high-speed operations.

- Environmental sensitivity: Standard PCs are not always suitable for harsh industrial environments.

On the other hand, dedicated CNC controllers are purpose-built for machine control. These controllers offer:

- Robustness: They are designed to withstand harsh industrial environments.

- Reliability: With fewer components and a focused design, they are less prone to failures.

- Speed: Dedicated controllers can often process complex operations faster than PC-based systems.

- Real-time performance: They offer more consistent and predictable real-time control.

The drawbacks of dedicated CNC controllers include:

- Cost: They are typically more expensive than PC-based systems.

- Upgradability: It can be more challenging to update or add new features to dedicated controllers.

- Specialization: Operators may require specific training to use these systems effectively.

The choice between PC-based and dedicated CNC controllers for a CNC glass cutting machine often depends on the specific requirements of the glass cutting operation. For high-volume production environments where reliability and speed are paramount, dedicated CNC controllers are often the preferred choice. For smaller operations or those requiring frequent changes in production parameters, PC-based controllers might be more suitable.

Key Controller Features: Look-Ahead and Vibration Damping

Regardless of whether a CNC glass cutting machine uses a PC-based or dedicated controller, there are several key features that are essential for optimal performance in glass cutting applications. Two of the most critical features are look-ahead capabilities and vibration damping.

Look-ahead technology is a crucial feature in modern CNC controllers. This capability allows the controller to analyze and process upcoming movements in advance, enabling smoother and more accurate cutting paths. In glass cutting, where precision is paramount, look-ahead technology offers several benefits:

- Improved accuracy: By anticipating upcoming movements, the controller can adjust speeds and accelerations to maintain precision throughout the cutting process.

- Reduced wear and tear: Smoother movements result in less stress on the machine's components, potentially extending equipment life.

- Enhanced surface finish: Look-ahead capabilities contribute to cleaner cuts and better edge quality in glass products.

- Increased productivity: By optimizing cutting paths and speeds, look-ahead technology can reduce overall processing time.

The number of blocks a controller can look ahead varies, with more advanced systems capable of analyzing hundreds or even thousands of blocks in advance. This extended look-ahead capability is particularly beneficial for complex glass cutting operations involving intricate shapes or patterns.

Vibration damping is another critical feature in CNC glass cutting machine controllers. Glass, being a brittle material, is particularly susceptible to cracking or chipping due to vibrations during the cutting process. Effective vibration damping contributes to:

- Improved cut quality: By minimizing vibrations, the controller helps ensure cleaner, more precise cuts.

- Reduced waste: Less vibration means fewer instances of cracked or chipped glass, reducing material waste.

- Extended tool life: Damping vibrations can help prolong the life of cutting tools, reducing maintenance costs.

- Increased cutting speeds: With better vibration control, machines can often operate at higher speeds without compromising quality.

Advanced CNC controllers employ various techniques for vibration damping, including:

- Adaptive feed control: Adjusting feed rates based on real-time vibration measurements.

- Harmonic suppression: Identifying and counteracting specific frequencies that cause problematic vibrations.

- Intelligent acceleration/deceleration: Optimizing speed changes to minimize vibration-inducing jolts.

The effectiveness of these vibration damping features can significantly impact the overall performance and output quality of a CNC glass cutting machine from China CNC glass cutting machine manufacturers. When selecting a machine or upgrading an existing system, it's crucial to consider the sophistication of the controller's vibration damping capabilities, especially for high-precision or high-speed glass cutting applications.

The Role of the Controller in User Interface and Connectivity

The controller in a CNC glass cutting machine plays a vital role beyond just managing the cutting process. It serves as the primary interface between the operator and the machine, and increasingly, between the machine and the broader production ecosystem. As such, the user interface (UI) and connectivity features of the controller are becoming increasingly important considerations.

Modern CNC controllers for glass cutting machines typically feature advanced user interfaces designed to enhance operator efficiency and reduce the likelihood of errors. These interfaces often include:

- Touchscreen displays: Large, high-resolution touchscreens allow for intuitive interaction and clear visualization of cutting patterns and machine status.

- Graphical programming: Many controllers now offer the ability to create cutting programs through graphical interfaces, reducing the need for complex G-code programming.

- Simulation capabilities: Before executing a cut, operators can simulate the process to identify potential issues or optimize cutting paths.

- Multi-language support: To accommodate global workforces, controllers often support multiple languages.

- Customizable dashboards: Operators can often configure the interface to display the most relevant information for their specific tasks.

These user-friendly interfaces contribute to reduced training times, fewer operator errors, and increased overall productivity. They also allow for more complex cutting operations to be performed by less specialized personnel, providing flexibility in workforce management.

Connectivity is another area where modern CNC controllers excel. As Industry 4.0 concepts continue to gain traction, the ability of CNC glass cutting machines to communicate with other systems and devices becomes increasingly important. Advanced controllers often offer:

- Network connectivity: Ethernet or Wi-Fi capabilities allow for seamless integration with factory networks.

- Remote monitoring and control: Operators and managers can monitor machine status and even control operations from remote locations.

- Data logging and analytics: Controllers can collect and analyze operational data, providing insights for process optimization and predictive maintenance.

- Integration with MES and ERP systems: This allows for better production planning and resource management.

- Cloud connectivity: Some controllers offer cloud-based services for data storage, software updates, and remote support.

These connectivity features enable CNC glass cutting machines to become part of a larger, interconnected manufacturing ecosystem. This integration can lead to significant improvements in overall production efficiency, quality control, and responsiveness to changing market demands.

For example, a networked CNC glass cutting machine from China CNC glass cutting machine manufacturers could receive cutting patterns directly from a design department, report its operational status to a central production management system, and automatically order replacement parts based on its maintenance schedule. This level of integration can dramatically streamline operations and reduce downtime.

Moreover, the data collected by these connected controllers can be invaluable for continuous improvement efforts. By analyzing patterns in production data, manufacturers can identify bottlenecks, optimize cutting paths, and even predict potential equipment failures before they occur.

As the glass industry continues to evolve, the role of the controller in CNC glass cutting machines is likely to become even more central. Future developments may include enhanced artificial intelligence capabilities for autonomous optimization, augmented reality interfaces for easier operation and maintenance, and even more sophisticated connectivity options to support fully automated smart factories.

Conclusion

The type of controller used in a CNC glass cutting machine is a critical factor in determining the machine's performance, ease of use, and ability to integrate with modern manufacturing systems. Whether opting for a PC-based or dedicated CNC controller, manufacturers should carefully consider factors such as look-ahead capabilities, vibration damping, user interface design, and connectivity options to ensure they select a system that best meets their current needs and future aspirations.

Ready to Upgrade Your Glass Cutting Capabilities?

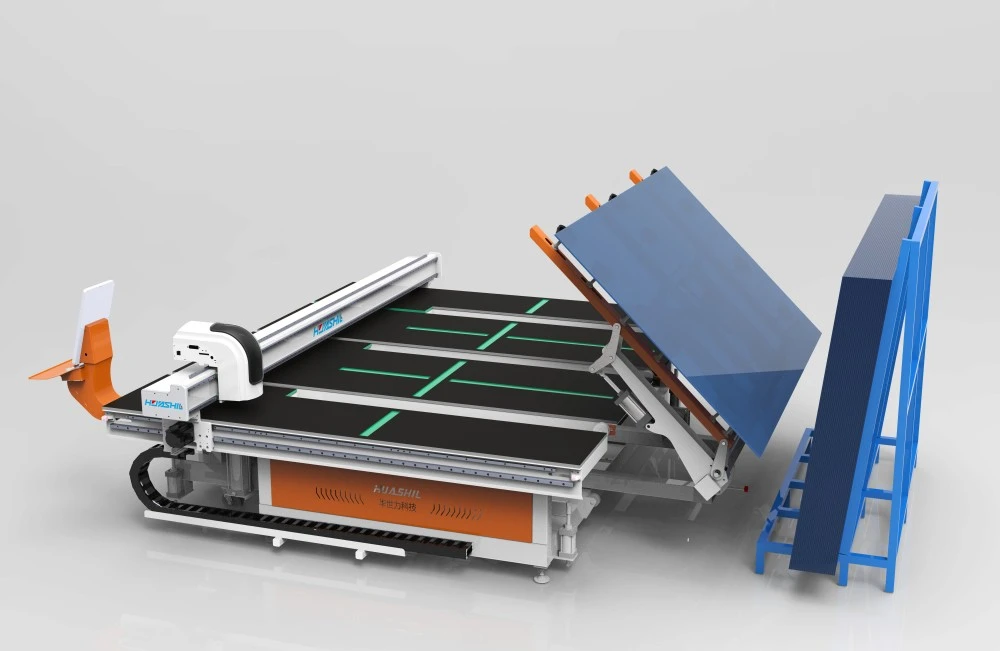

At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that advanced CNC controllers play in modern glass cutting operations. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment have positioned us as leaders in providing cutting-edge CNC glass cutting solutions. Whether you're looking to upgrade your existing equipment or invest in new, state-of-the-art glass cutting machinery, our team of experts is here to help. We offer a range of CNC glass cutting machines featuring advanced controllers that combine precision, efficiency, and user-friendly interfaces. Our solutions are designed to meet the diverse needs of industries ranging from automotive and architecture to smart mirrors and decorative glass. Experience the Huashil difference – where advanced technology meets unparalleled service and support. Contact us today to discuss how we can elevate your glass cutting operations to new heights of productivity and quality.

FAQ

1. What are the main types of controllers used in CNC glass cutting machines?

The two main types of controllers used in CNC glass cutting machines are PC-based controllers and dedicated CNC controllers. Each type has its own advantages and is suitable for different production environments and requirements.

2. How does look-ahead technology benefit glass cutting operations?

Look-ahead technology in CNC controllers improves cutting accuracy, reduces wear and tear on machine components, enhances surface finish quality, and increases overall productivity by optimizing cutting paths and speeds.

3. Why is vibration damping important in CNC glass cutting machines?

Vibration damping is crucial in glass cutting as it improves cut quality, reduces waste from cracked or chipped glass, extends tool life, and allows for higher cutting speeds without compromising precision.

4. How do modern CNC controllers contribute to Industry 4.0 integration?

Modern CNC controllers offer advanced connectivity features such as network integration, remote monitoring and control, data logging and analytics, and integration with MES and ERP systems, enabling glass cutting machines to become part of a larger, interconnected manufacturing ecosystem.

Choose the Right CNC Glass Cutting Machine for Your Needs | HUASHIL

Are you looking to enhance your glass cutting capabilities with a state-of-the-art CNC machine? Look no further than Shandong Huashil Automation Technology Co., LTD. Our range of CNC glass cutting machines combines advanced controller technology with robust engineering to deliver unparalleled precision and efficiency. Whether you need a machine for architectural glass, automotive applications, or decorative glass production, we have the perfect solution for you. Our team of experts is ready to guide you through the selection process, ensuring you get a machine that perfectly fits your production needs and budget. Don't settle for less when it comes to your glass cutting equipment. Contact us today at salescathy@sdhuashil.com to discuss your requirements and take the first step towards optimizing your glass cutting operations with Huashil's cutting-edge technology.

References

1. Smith, J. (2022). "Advanced Control Systems in CNC Glass Cutting: A Comprehensive Review." Journal of Glass Technology, 45(3), 112-128.

2. Johnson, A., & Lee, S. (2021). "Comparative Analysis of PC-Based and Dedicated CNC Controllers in Glass Manufacturing." International Conference on Industrial Automation, 789-801.

3. Chen, X., et al. (2023). "Impact of Look-Ahead Technology on Precision Glass Cutting: A Case Study." Applied Glass Science, 18(2), 245-260.

4. Wilson, R. (2022). "The Role of Vibration Damping in High-Speed Glass Cutting Processes." Journal of Manufacturing Technology, 37(4), 501-515.