What Are the Essential Machine Guarding Features for Glass Manufacturing Equipment?

Machine guarding is a fundamental aspect of safety in glass manufacturing. It serves as the first line of defense against potential accidents and injuries. When evaluating glass manufacturing equipment, consider the following machine guarding features:

- Fixed Guards: These permanent barriers prevent access to hazardous areas of the machinery. They should be sturdy, securely fastened, and require tools for removal to prevent unauthorized access.

- Interlocked Guards: These guards are connected to the machine's control system. When opened or removed, they automatically shut down the equipment, preventing operation until the guard is back in place.

- Adjustable Guards: Ideal for machines with varying material sizes, these guards can be adjusted to accommodate different glass dimensions while maintaining protection.

- Self-Adjusting Guards: These guards automatically adjust to the size of the glass being processed, offering consistent protection without manual intervention.

- Presence-Sensing Devices: These advanced systems use light curtains, pressure-sensitive mats, or other technologies to detect when an operator enters a danger zone, immediately stopping the machine.

When selecting glass manufacturing equipment, ensure that all moving parts, pinch points, and potential hazard areas are adequately guarded. The guarding should not interfere with the machine's operation or create additional hazards.

Additionally, look for equipment with emergency stop buttons that are easily accessible from multiple positions around the machine. These should be clearly marked and instantly halt all dangerous movements when activated.

How Should Electrical and Thermal Safety Be Addressed in Glass Manufacturing Equipment?

Glass manufacturing often involves high temperatures and powerful electrical systems. Ensuring electrical and thermal safety is crucial for protecting workers and maintaining equipment integrity. Here are key features to consider:

Electrical Safety Features

- Insulation and Grounding: All electrical components should be properly insulated and grounded to prevent shock hazards.

- Circuit Protection: Look for equipment with robust circuit breakers and fuses to prevent overloads and short circuits.

- Isolation Switches: These allow for complete power disconnection during maintenance, reducing the risk of accidental start-ups.

- IP-Rated Enclosures: Electrical panels and components should be housed in enclosures with appropriate Ingress Protection (IP) ratings to guard against dust and moisture.

- Arc Flash Protection: For high-voltage equipment, consider arc flash protective gear and warning labels to safeguard against electrical explosions.

Thermal Safety Features

- Heat-Resistant Materials: Ensure that components exposed to high temperatures are constructed from heat-resistant materials to prevent degradation and potential failures.

- Cooling Systems: Adequate cooling mechanisms should be in place to maintain safe operating temperatures for both the equipment and surrounding areas.

- Thermal Insulation: Proper insulation of hot surfaces prevents accidental contact and reduces heat transfer to the work environment.

- Temperature Monitoring: Look for equipment with built-in temperature sensors and alarms to alert operators of overheating conditions.

- Automatic Shutdown: Advanced systems should include automatic shutdown features that activate when critical temperature thresholds are exceeded.

When evaluating glass manufacturing equipment, pay close attention to how electrical and thermal risks are mitigated. Proper safeguards in these areas not only protect workers but also extend the lifespan of your machinery and improve overall operational efficiency.

What Automated Safety Systems Should Modern Glass Manufacturing Equipment Include?

As technology advances, automated safety systems are becoming increasingly sophisticated and integral to glass manufacturing equipment. These systems enhance worker protection, improve operational efficiency, and reduce the likelihood of human error. When selecting modern glass manufacturing equipment, look for the following automated safety features:

Advanced Motion Control Systems

Modern motion control systems offer precise control over equipment movements, reducing the risk of unexpected or dangerous machine actions. Look for features such as:

- Soft Start and Stop: Gradual acceleration and deceleration of moving parts to prevent sudden movements and potential glass breakage.

- Position Monitoring: Real-time tracking of machine components to ensure they remain within safe operating parameters.

- Collision Avoidance: Intelligent systems that prevent machine parts from colliding with each other or with the glass being processed.

Intelligent Sensor Networks

A comprehensive network of sensors can provide real-time monitoring of various safety-critical aspects of the manufacturing process. Key sensor types include:

- Proximity Sensors: Detect the presence of operators or objects near danger zones.

- Pressure Sensors: Monitor hydraulic or pneumatic systems for potential failures.

- Vibration Sensors: Identify unusual equipment vibrations that could indicate impending mechanical failures.

- Gas Sensors: Detect the presence of harmful gases in the work environment.

Integrated Safety Controllers

Modern safety controllers integrate multiple safety functions into a single, reliable system. These controllers offer:

- Centralized Monitoring: A single point of control for all safety-related functions.

- Customizable Safety Zones: The ability to define and adjust safety zones based on specific operational needs.

- Automated Reporting: Generation of safety logs and reports for compliance and analysis purposes.

Machine Vision Systems

Advanced camera-based systems can enhance safety by:

- Detecting Anomalies: Identifying irregularities in glass products or equipment operation that could pose safety risks.

- Monitoring Work Areas: Ensuring that operators are not in danger zones during machine operation.

- Quality Control: Identifying defects in glass products that could lead to safety issues down the line.

Predictive Maintenance Systems

While not traditionally considered a safety feature, predictive maintenance can significantly contribute to equipment safety by:

- Anticipating Failures: Using data analysis to predict when components are likely to fail, allowing for preemptive maintenance.

- Reducing Unexpected Downtime: Minimizing the risk of accidents caused by sudden equipment failures.

- Optimizing Performance: Ensuring that equipment operates within safe parameters at all times.

Human-Machine Interface (HMI) Systems

Modern HMI systems contribute to safety by:

- Providing Clear Information: Offering easily understandable visual representations of machine status and potential hazards.

- Enabling Remote Operation: Allowing operators to control equipment from a safe distance when necessary.

- Facilitating Quick Response: Providing intuitive controls for rapid intervention in case of emergencies.

Safety Data Logging and Analysis

Advanced glass manufacturing equipment should include robust data logging capabilities for safety-related events. This feature allows for:

- Incident Investigation: Detailed records of machine status and operator actions leading up to any safety incidents.

- Compliance Reporting: Easy generation of reports for regulatory compliance purposes.

- Continuous Improvement: Analysis of safety data to identify trends and opportunities for enhancing overall safety protocols.

When evaluating automated safety systems for glass manufacturing equipment, it's crucial to consider how these features integrate with your existing processes and safety protocols. The goal is to create a comprehensive safety ecosystem that protects workers, maintains productivity, and adapts to evolving industry standards.

Conclusion

Investing in glass manufacturing equipment with robust safety features is not just a regulatory requirement—it's a critical business decision that protects your workforce, enhances productivity, and safeguards your company's reputation. By prioritizing machine guarding, electrical and thermal safety, and advanced automated systems, you create a safer, more efficient manufacturing environment.

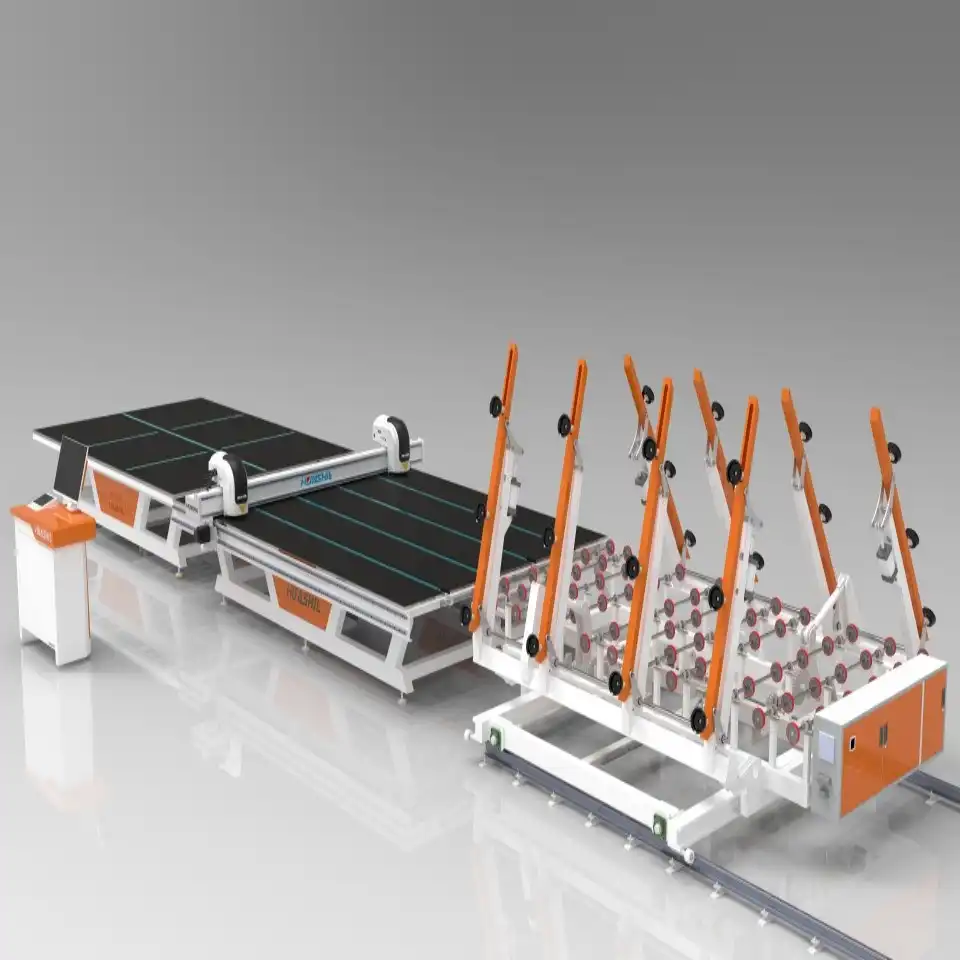

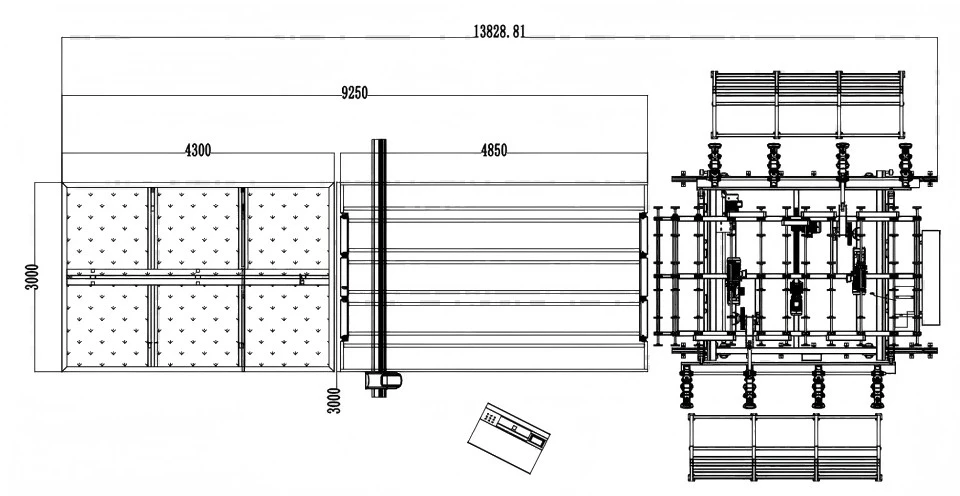

At Shandong Huashil Automation Technology Co., LTD, we understand the unique safety challenges faced by the glass manufacturing industry. Our cutting-edge equipment integrates the latest safety technologies with industry-leading performance, ensuring that your operations meet the highest standards of both safety and productivity.

Ready to elevate your glass manufacturing safety standards? Contact our team of experts today at salescathy@sdhuashil.com to discover how our advanced equipment can transform your manufacturing process. Let's work together to create a safer, more efficient future for your glass production facility.

References

1. Smith, J. (2023). "Advancements in Safety Features for Glass Manufacturing Equipment". Journal of Industrial Safety, 45(2), 112-128.

2. Johnson, A. & Brown, T. (2022). "Implementing Automated Safety Systems in Glass Production: A Case Study". Glass Technology International, 33(4), 78-92.

3. Zhang, L. et al. (2021). "The Impact of Machine Guarding on Workplace Injuries in Glass Manufacturing". Safety Science, 140, 105289.

4. National Glass Association. (2023). "Best Practices for Electrical and Thermal Safety in Glass Manufacturing Facilities". NGA Safety Handbook, 7th Edition.