In today's fast-paced glass manufacturing industry, efficiency and speed are paramount to meeting production demands. One of the most critical factors in the glass processing workflow is the loading speed of glass cutting loading machines. These sophisticated pieces of equipment are designed to precisely handle, position, and prepare glass sheets for cutting operations. The loading speed directly impacts overall production throughput, making it a crucial consideration for manufacturers seeking to optimize their operations.

What Factors Affect the Speed of Glass Cutting Loading Machines?

Machine Technology and Design

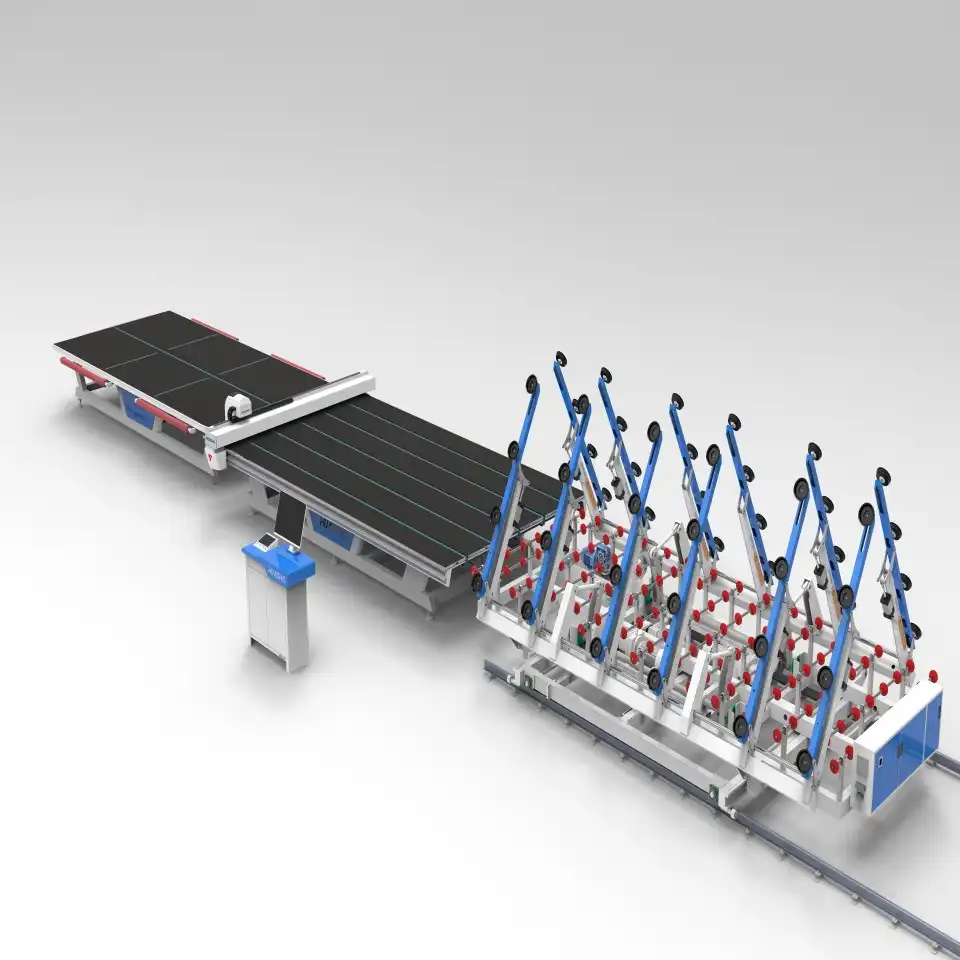

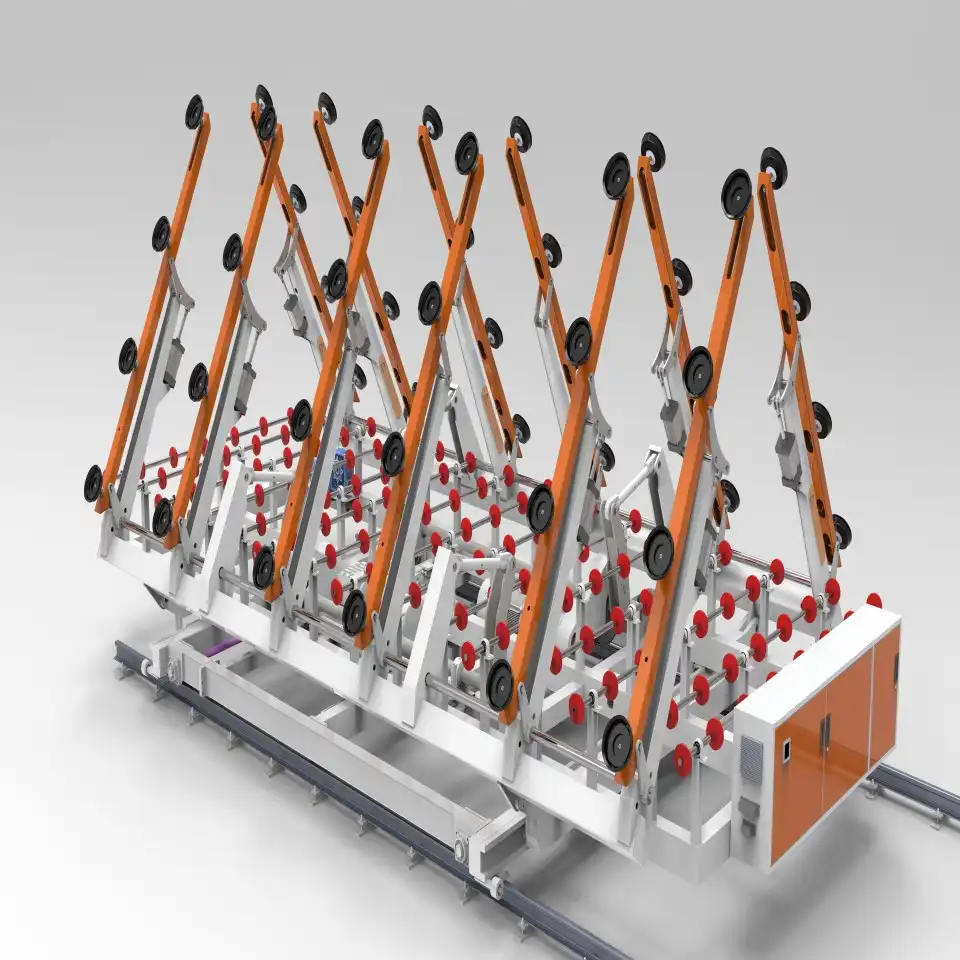

The technology incorporated into glass cutting loading machines significantly influences their operational speed. Modern glass cutting loading machines utilize advanced servo motors, precision linear guides, and intelligent control systems that work in harmony to achieve optimal loading speeds. High-performance models can complete a loading cycle in as little as 8-15 seconds, depending on the glass size and thickness. Manufacturers like Huashil have developed glass cutting loading machines with innovative vacuum lifting systems that can securely grasp glass sheets and position them on the cutting table with minimal time loss. The structural design of the machine, including its frame rigidity and component layout, also plays a crucial role in determining how quickly it can execute loading movements without compromising precision or safety.

Glass Specifications and Dimensions

The physical characteristics of the glass being processed have a direct impact on loading speed. A glass cutting loading machine typically handles glass sheets ranging from 2mm to 19mm in thickness with varying degrees of efficiency. Thinner glass requires more delicate handling, which may slightly reduce loading speeds to prevent breakage. Similarly, larger glass dimensions necessitate more careful positioning and may extend the loading cycle time. Most industrial glass cutting loading machines are optimized to handle standard glass sizes (3300mm × 2440mm or 3660mm × 2440mm) with maximum efficiency. Custom-sized or irregularly shaped glass may require additional positioning time. The weight of the glass sheet is another critical factor - heavier sheets require more robust lifting mechanisms and potentially slower movement to maintain safety and precision.

Automation Level and Integration

The degree of automation incorporated into a glass cutting loading machine dramatically affects its loading speed. Fully automated glass cutting loading machines with integrated robotic systems can achieve consistent loading times of 12-18 seconds per cycle for standard glass sizes. These systems utilize advanced vision systems for glass detection, automated edge alignment, and synchronized movements to eliminate manual intervention and reduce loading times. Semi-automated machines that require some operator input typically have loading times of 20-30 seconds per cycle, with the variation depending on operator skill and experience. The integration of the glass cutting loading machine with upstream and downstream processes also impacts overall throughput, as seamless communication between different processing stations minimizes waiting times and buffer requirements.

How Does Glass Cutting Loading Machine Speed Compare to Manual Loading?

Time Efficiency Analysis

When comparing the operational efficiency of automated glass cutting loading machines to manual loading methods, the difference is substantial. Manual loading of glass sheets typically requires 2-4 workers and takes approximately 45-90 seconds per sheet, depending on the size and weight of the glass. This process is not only time-consuming but also inconsistent, with loading times varying based on worker fatigue and skill levels. In contrast, modern glass cutting loading machines can consistently achieve loading cycles of 10-20 seconds for similar glass sheets. Over the course of a standard 8-hour production shift, a glass cutting loading machine can handle between 1,440 and 2,880 loading cycles (assuming continuous operation), compared to just 320-640 cycles for a manual team. This represents a productivity increase of 350-450%, significantly enhancing production capacity without expanding facility space or shifting hours.

Precision and Consistency Factors

Beyond pure speed, glass cutting loading machines offer superior precision and consistency that manual loading cannot match. Automated systems position glass sheets with accuracy up to ±0.5mm, ensuring optimal alignment for cutting operations. This precision is maintained throughout the production run, regardless of how many hours the machine has been operating. Manual loading, even by experienced workers, typically achieves positioning accuracy of only ±2-5mm, with accuracy deteriorating over time due to fatigue. The consistent positioning provided by glass cutting loading machines leads to higher quality cuts, reduced waste, and fewer rejections. Additionally, modern glass cutting loading machines incorporate real-time position verification systems that can detect and correct misalignments before the cutting process begins, further reducing the potential for errors and the need for rework.

Labor Requirements and Safety Considerations

The labor requirements for operating glass cutting loading machines are significantly lower than for manual loading processes. While manual loading typically requires 2-4 workers per cutting station, a glass cutting loading machine can be operated by a single technician who primarily monitors the system and manages material flow. This reduction in labor not only lowers operational costs but also addresses the growing skilled labor shortage in manufacturing industries. From a safety perspective, glass cutting loading machines substantially reduce the risk of workplace injuries. Manual handling of large, heavy glass sheets poses significant risks including cuts, strains, and crushing injuries. Glass cutting loading machines eliminate these risks by automating the heavy lifting and precise positioning tasks. Modern systems incorporate multiple safety features including pressure-sensitive stopping mechanisms, light curtains, and emergency stop functions that protect both operators and the glass material from damage during the loading process.

What Innovations Are Improving Glass Cutting Loading Machine Speed?

Advanced Vacuum and Lifting Technologies

Recent innovations in vacuum and lifting technologies have significantly enhanced the speed and efficiency of glass cutting loading machines. The latest generation of machines incorporates multi-zone vacuum systems that can be dynamically adjusted based on the glass size and weight. This technology enables faster secure gripping and release of glass sheets, reducing cycle times by 15-20% compared to conventional systems. Advanced glass cutting loading machines now feature intelligent vacuum control systems that continuously monitor and adjust suction levels, preventing glass slippage while minimizing energy consumption. Some cutting-edge models employ dual-circuit vacuum systems with redundancy, which allows for continuous operation even if one circuit experiences reduced pressure, eliminating downtime and maintaining consistent loading speeds. Additionally, lightweight composite materials are being used in vacuum frames and lifting components, reducing inertia and enabling faster acceleration and deceleration without compromising structural integrity.

Artificial Intelligence and Machine Learning Applications

The integration of artificial intelligence and machine learning algorithms is revolutionizing glass cutting loading machine operations. Smart glass cutting loading machines now utilize predictive algorithms that optimize loading paths and speeds based on glass characteristics and production requirements. Machine learning systems continuously analyze operational data to identify patterns and optimize movement sequences, gradually improving loading speeds over time without manual reprogramming. Computer vision systems with deep learning capabilities can instantly recognize glass types, dimensions, and potential defects, automatically adjusting handling parameters for optimal speed and safety. These AI-enhanced glass cutting loading machines can reduce setup times between different glass types by up to 80%, significantly improving overall production efficiency. The implementation of digital twins and simulation models allows for virtual testing and optimization of loading sequences before physical implementation, reducing the risk of downtime and accelerating the deployment of speed improvements.

Integration with Industry 4.0 and IoT Systems

The convergence of glass cutting loading machines with Industry 4.0 technologies and Internet of Things (IoT) systems is driving substantial improvements in operational speed. Modern glass cutting loading machines feature comprehensive sensor networks that continuously monitor all aspects of machine performance, enabling real-time optimization of loading speeds while preventing conditions that could lead to downtime. IoT-enabled glass cutting loading machines can communicate with upstream and downstream equipment, automatically adjusting loading speeds to match the pace of connected processes and eliminating bottlenecks. Cloud-based analytics platforms process operational data from glass cutting loading machines across multiple facilities, identifying best practices and optimal settings that can be remotely deployed to all connected machines. Remote monitoring and predictive maintenance capabilities ensure that glass cutting loading machines consistently operate at peak performance levels, minimizing speed reductions that typically occur as components wear over time. Additionally, digital workflow management systems optimize material flow and production scheduling, ensuring that glass cutting loading machines are consistently supplied with materials at the optimal rate.

Conclusion

The speed of glass cutting loading machines has evolved dramatically, with modern systems capable of completing loading cycles in 8-20 seconds depending on glass specifications and machine configuration. These advancements in loading technology, driven by automation, AI integration, and innovative lifting systems, have revolutionized glass processing efficiency. As the industry continues to evolve, we can expect further improvements in loading speeds while maintaining the precision and safety that are essential in glass manufacturing operations.

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include Mirror Cutting Machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Chen, L., & Zhang, P. (2023). Advancements in Automation Technologies for Glass Processing Industries. Journal of Manufacturing Technology, 45(3), 218-232.

2. Williams, R., & Johnson, K. (2022). Comparative Analysis of Manual versus Automated Glass Handling Systems in Modern Manufacturing. International Journal of Industrial Engineering, 18(2), 145-159.

3. Kowalski, M., & Schmidt, T. (2023). Integration of Machine Learning Algorithms in Glass Processing Equipment. Automation Research Quarterly, 36(4), 312-325.

4. Liu, H., Wang, Y., & Thompson, S. (2022). Speed Optimization in Glass Cutting Equipment: Technical Parameters and Operational Considerations. Journal of Glass Processing Technology, 29(1), 75-91.

5. Anderson, J., & García, L. (2023). Industry 4.0 Implementation in Glass Manufacturing: Case Studies and Best Practices. Smart Manufacturing Systems, 14(2), 167-181.

6. Patel, V., & Nakamura, T. (2022). Vacuum Technology Innovations for Material Handling in Glass Processing. Journal of Industrial Automation, 52(3), 245-259.