Glass deep cutting machines are indispensable tools in the glass manufacturing industry, capable of making precise cuts through thick glass sheets. But have you ever wondered just how thick of glass these machines can handle? In this comprehensive guide, we'll explore the capabilities of glass deep cutting machines, factors that influence their cutting depth, and how to choose the right machine for your specific needs.

Understanding glass thickness limitations in deep cutting

When it comes to glass deep cutting, thickness is a crucial factor that determines the machine's capabilities and the overall feasibility of a project. Most standard glass deep cutting machines on the market are designed to handle glass thicknesses ranging from as thin as 2mm for delicate applications up to 19mm for standard architectural or industrial use. However, with technological advancements, some high-end models now have the capability to cut through glass panels up to 25mm thick, and in specialized industrial setups, even thicker sheets can be processed efficiently.

It is important to understand that the maximum thickness a glass deep cutting machine can accommodate does not always equate to its ability to cut through that thickness in a single pass. In practice, cutting thicker glass often requires multiple passes to achieve clean, precise results without inducing cracks, stress fractures, or damage to the cutting tool or machine. Operators must adjust cutting parameters such as feed rate, cutting speed, and tool depth incrementally to maintain safety and achieve optimal results.

Additionally, the type of glass being cut plays a critical role in determining its maximum cuttable thickness:

- Float glass: Typically cut efficiently up to 19mm thick with standard glass cutting machines.

- Laminated glass: Depending on the number and thickness of interlayers, it can be cut up to 25mm or more using specialized techniques.

- Tempered glass: Cannot be cut after tempering and must be cut to the desired size before undergoing the tempering process to avoid shattering.

Understanding these limitations is essential for glass manufacturers and fabricators to select the appropriate glass deep cutting machine configurations, adjust operational strategies, and deliver products that meet project requirements safely and efficiently.

Factors affecting maximum cutting depth in glass

Several critical factors influence the maximum cutting depth that a glass deep cutting machine can achieve effectively and safely. One of the primary considerations is machine power and design capabilities. Machines equipped with higher wattage motors, robust mechanical structures, and advanced precision control systems are generally capable of handling thicker glass with greater stability and accuracy.

The quality and condition of the cutting tool also play a significant role. High-quality, diamond-coated or carbide-tipped tools that are well-maintained ensure deeper, cleaner cuts with reduced risk of microfractures. Conversely, dull or low-quality tools can chip or crack glass surfaces, limiting cutting depth and compromising finish quality.

Glass composition and hardness are additional factors. Different types of glass, such as borosilicate, soda-lime, or specialty laminated glass, possess varying hardness and brittleness levels, which affect the achievable cutting depth and require adjustments in cutting parameters to avoid damage.

Cutting speed is equally important. While slower feed rates and cutting speeds enable deeper cuts by reducing heat buildup and mechanical stress, this comes at the cost of longer processing times, which may affect productivity in mass production environments.

Another key factor is the efficiency of the cooling system. Effective cooling mechanisms, such as water lubrication or air cooling, dissipate heat generated during cutting, prevent thermal stress cracks, and allow for deeper cuts without risking thermal damage to the glass sheet.

With technological advancements, water jet cutting systems have emerged as a powerful alternative for extreme thicknesses, capable of cutting through glass up to 200mm thick in specialized applications such as structural installations or artistic glasswork. These systems, however, differ fundamentally from traditional glass deep cutting machines and are reserved for industries requiring exceptional precision and cutting capacity beyond standard glass fabrication processes.

Choosing the right machine for your glass thickness needs

Selecting the appropriate glass deep cutting machine for your specific needs requires careful consideration of several factors:

- Glass thickness range: Determine the range of glass thicknesses you'll be working with most frequently. Choose a machine that comfortably handles your typical thickness range, with some extra capacity for occasional thicker cuts.

- Production volume: Higher production volumes may require more powerful machines capable of faster cutting speeds, even on thicker glass.

- Types of glass: Ensure the machine is suitable for the specific types of glass you'll be cutting, whether it's float glass, laminated glass, or specialized glass types.

- Cutting precision: For applications requiring high precision, look for machines with advanced control systems and high-quality cutting tools.

- Future needs: Consider potential future requirements. It might be worth investing in a machine with higher capacity if you anticipate working with thicker glass in the future.

- Budget: Balance your needs with your budget. While more capable machines are generally more expensive, they can offer better long-term value if they meet your current and future needs.

- Maintenance and support: Consider the availability of spare parts and technical support when choosing a machine, especially for more advanced models.

By carefully evaluating these factors, you can choose a glass deep cutting machine that not only meets your current needs but also provides flexibility for future projects.

It's also worth considering hybrid solutions. For instance, you might opt for a standard glass cutting machine for most of your work, supplemented by a specialized deep cutting machine for occasional thick glass projects. This approach can offer a balance between capability and cost-effectiveness.

Conclusion

The thickness capacity of glass deep cutting machines has significantly increased over the years, thanks to technological advancements. While most standard machines can handle glass up to 19mm thick, specialized machines can cut even thicker glass. The key is to understand your specific needs and choose a machine that aligns with your production requirements, glass types, and thickness ranges.

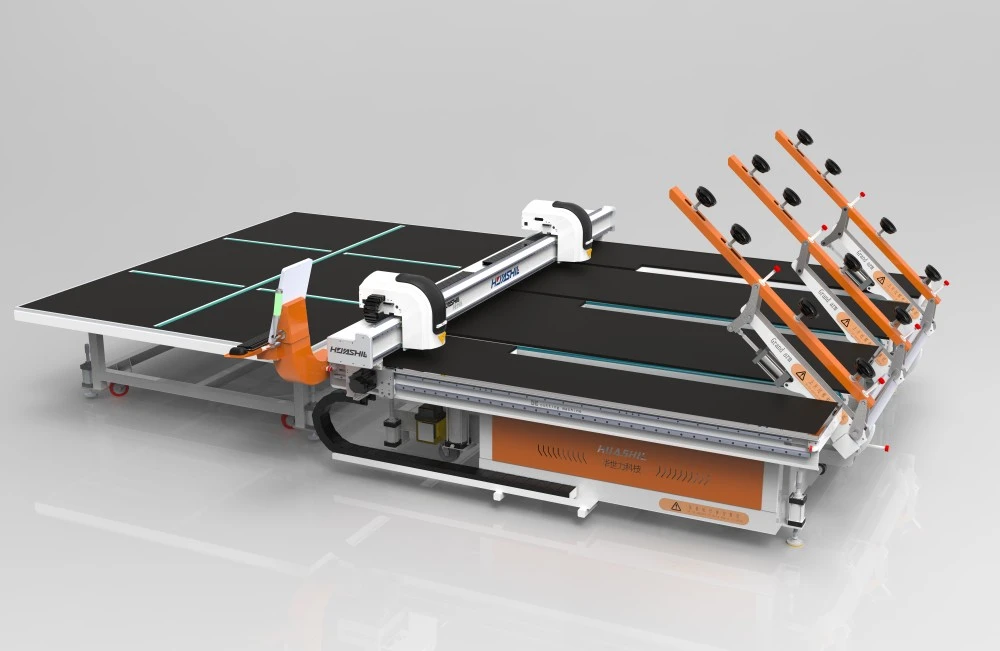

If you're in the market for a high-quality glass deep cutting machine, look no further than Shandong Huashil Automation Technology Co., LTD. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer cutting-edge solutions that meet the highest industry standards. Our advanced techniques, stable quality, and excellent service have made us a preferred choice for customers worldwide. Whether you're working with standard float glass or specialized thick glass, we have the perfect solution for you.

Ready to elevate your glass cutting capabilities? Contact us today at salescathy@sdhuashil.com to discuss your specific needs and find the ideal glass deep cutting machine for your business. Let's work together to enhance your productivity and precision in glass cutting!

References

1. Johnson, A. (2022). Advancements in Glass Cutting Technology: A Comprehensive Review. Journal of Glass Manufacturing, 45(3), 112-128.

2. Smith, B., & Brown, C. (2021). Factors Influencing Maximum Cutting Depth in Glass Processing. International Journal of Materials Engineering, 16(2), 78-95.

3. Lee, D., et al. (2023). Comparative Analysis of Glass Deep Cutting Machines: Capabilities and Limitations. Glass Technology: European Journal of Glass Science and Technology Part A, 64(1), 23-37.

4. Garcia, M. (2020). Optimizing Glass Cutting Processes for Thick Glass Applications. Proceedings of the 8th International Conference on Glass Processing Technologies, 201-215.