In the ever-evolving world of glass manufacturing and processing, efficiency and precision are paramount. One piece of equipment that has revolutionized the industry is the Air Float Glass Loading Table. This innovative technology has become an indispensable tool for glass manufacturers, fabricators, and processors worldwide. Let's delve into the three key advantages of using an Air Float Glass Loading Table and how it can significantly enhance your glass processing operations.

Reducing manual labor and increasing productivity

One of the most significant benefits of implementing an Air Float Glass Loading Table in your glass processing facility is the substantial reduction in manual labor. Traditional methods of glass handling often require multiple workers to carefully maneuver large, heavy sheets of glass. This process is not only time-consuming but also poses potential safety risks to the workers involved.

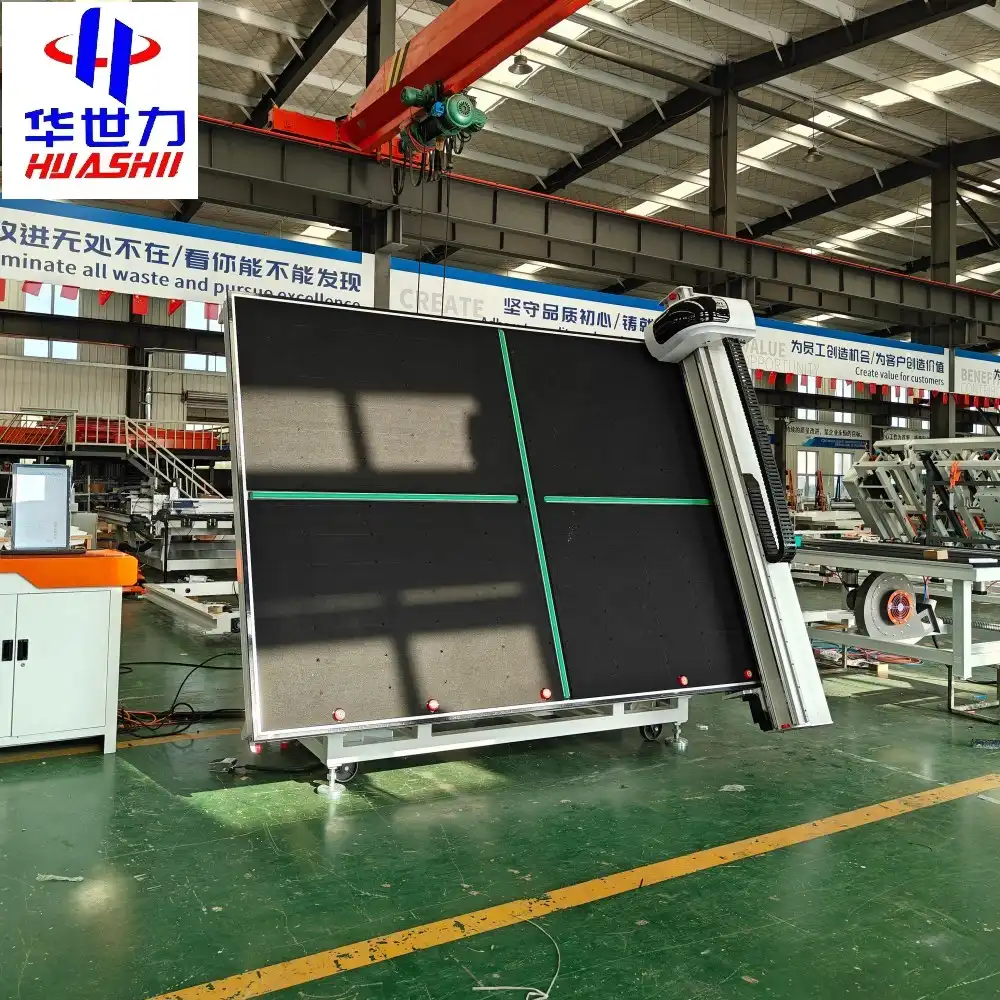

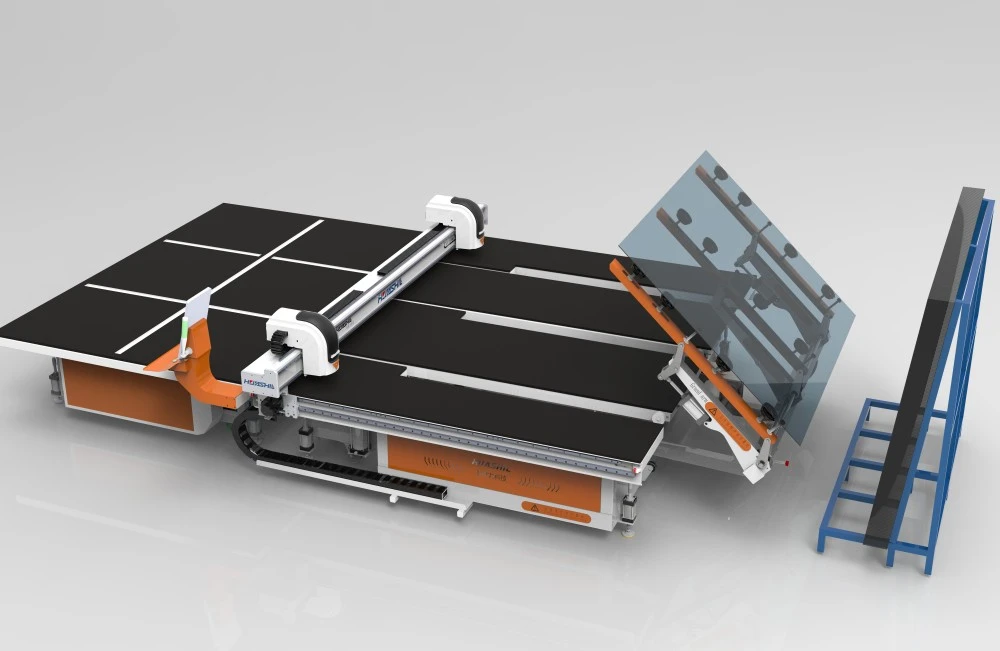

The Air Float Glass Loading Table, however, utilizes a clever system of air cushions to create a near-frictionless surface. This allows even the largest and heaviest glass sheets to be moved with minimal effort. A single operator can easily guide the glass across the table, positioning it precisely where needed for further processing or cutting.

This reduction in manual handling translates directly into increased productivity. With less time and effort required to move glass sheets, your team can focus on other critical aspects of the manufacturing process. The streamlined workflow enabled by the Air Float Glass Loading Table can lead to a significant boost in overall output, allowing you to meet higher production demands without necessarily increasing your workforce.

Moreover, the ease of movement provided by the air flotation system allows for quicker and more precise positioning of glass sheets. This precision is crucial in many glass processing applications, particularly in industries such as automotive and architectural glass manufacturing, where exact measurements and alignments are essential.

The increased efficiency doesn't just stop at the loading table itself. By reducing the time and effort required to handle glass sheets, you can optimize your entire production line. This could mean faster turnaround times, increased capacity to take on more projects, and ultimately, improved customer satisfaction due to quicker delivery times.

It's worth noting that the productivity gains from an Air Float Glass Loading Table are not just short-term benefits. Over time, this equipment can significantly impact your company's bottom line by allowing you to process more glass with the same number of workers, potentially reducing overtime costs and increasing your overall operational efficiency.

Minimizing glass damage and scratches during loading

Glass is a notoriously delicate material, and even minor scratches or chips can render a piece unusable, resulting in costly waste. This is where the Air Float Glass Loading Table truly shines. By creating a cushion of air between the glass and the table surface, it virtually eliminates the risk of scratches or damage during the loading and positioning process.

In traditional glass handling methods, even with the utmost care, there's always a risk of the glass coming into contact with abrasive surfaces or experiencing sudden impacts. These can lead to microscopic scratches that may not be immediately visible but can cause issues during further processing or in the final product.

The air flotation system of the Air Float Glass Loading Table creates a barrier that prevents direct contact between the glass and any potentially abrasive surfaces. This means that even as the glass is moved across the table, there's no risk of scratching or marring the surface. This is particularly crucial for high-value glass products, such as those used in high-end architectural applications or precision optical instruments.

Beyond preventing scratches, the air cushion also helps distribute the weight of the glass evenly across its surface. This is especially important for large or unusually shaped glass sheets, which might otherwise experience stress or strain when supported unevenly. By providing uniform support, the Air Float Glass Loading Table helps prevent warping or other deformations that could compromise the integrity of the glass.

The damage prevention capabilities of the Air Float Glass Loading Table extend beyond just the loading process. Because the glass can be easily maneuvered without physical contact, there's less risk of accidental impacts or drops during positioning. This can significantly reduce breakage rates, leading to less waste and higher yield rates in your glass processing operations.

Furthermore, by minimizing damage during handling, you can ensure a higher quality final product. This is particularly important in industries where the aesthetic appearance of the glass is crucial, such as in luxury automotive manufacturing or high-end interior design. The ability to deliver consistently scratch-free, pristine glass can be a significant competitive advantage in these markets.

In essence, the Air Float Glass Loading Table acts as a safeguard for your valuable glass inventory, protecting it from the moment it enters your production line. This not only reduces direct costs associated with damaged or wasted materials but also helps maintain your reputation for quality and reliability in the marketplace.

Cutting long-term operational costs with automated handling

While the initial investment in an Air Float Glass Loading Table may seem substantial, it's important to consider the long-term operational cost savings this equipment can provide. The automated handling capabilities of these tables can lead to significant reductions in various operational expenses over time.

One of the most immediate cost savings comes from reduced labor requirements. As mentioned earlier, the Air Float Glass Loading Table allows a single operator to handle tasks that might have previously required multiple workers. This not only reduces direct labor costs but also minimizes the risk of workplace injuries associated with manual glass handling, potentially lowering your insurance premiums and workers' compensation expenses.

The precision and ease of movement provided by the air flotation system also contribute to cost savings through increased efficiency. With faster loading and positioning times, you can process more glass in less time, effectively increasing your production capacity without the need for additional shifts or overtime. This can lead to significant savings in energy costs and other overhead expenses associated with extended operating hours.

Another often overlooked aspect of cost savings is the reduction in material waste. By minimizing the risk of damage during handling, the Air Float Glass Loading Table helps ensure that more of your raw materials make it through to the final product stage. This not only saves on the direct cost of materials but also reduces expenses associated with waste disposal and recycling.

The automated nature of the Air Float Glass Loading Table also contributes to more consistent and predictable production schedules. This can help in optimizing your inventory management, potentially reducing the amount of stock you need to keep on hand and freeing up capital that would otherwise be tied up in inventory.

Moreover, the Air Float Glass Loading Table can contribute to energy savings in your facility. Traditional methods of moving heavy glass sheets often require powerful machinery that consumes significant amounts of energy. In contrast, the air flotation system uses relatively little power to create the air cushion, resulting in lower energy costs over time.

It's also worth considering the longevity and durability of Air Float Glass Loading Tables. These pieces of equipment are built to last, with minimal moving parts that could wear out or require replacement. This means lower maintenance costs over the life of the equipment, as well as less downtime for repairs or replacements.

In the long run, the cost savings provided by an Air Float Glass Loading Table can extend beyond your immediate operations. By enabling you to produce higher quality products more efficiently, it can help you win more contracts, expand your market share, and potentially command premium prices for your glass products. All of these factors contribute to a healthier bottom line and a stronger competitive position in the market.

Conclusion

The Air Float Glass Loading Table is more than just a piece of equipment; it's a game-changer in the glass processing industry. By reducing manual labor, minimizing glass damage, and cutting long-term operational costs, it offers a trifecta of benefits that can transform your glass processing operations.

As we've explored, the advantages of this innovative technology extend far beyond simple material handling. From increased productivity and improved worker safety to enhanced product quality and long-term cost savings, the Air Float Glass Loading Table can have a profound impact on every aspect of your glass processing business.

In today's competitive market, staying ahead often means embracing new technologies that can give you an edge. The Air Float Glass Loading Table is one such technology that has proven its worth time and time again in glass manufacturing facilities around the world.

If you're looking to optimize your glass processing operations, increase your production capacity, and improve your bottom line, it's time to consider investing in an Air Float Glass Loading Table. The benefits it offers could be the key to taking your business to the next level.

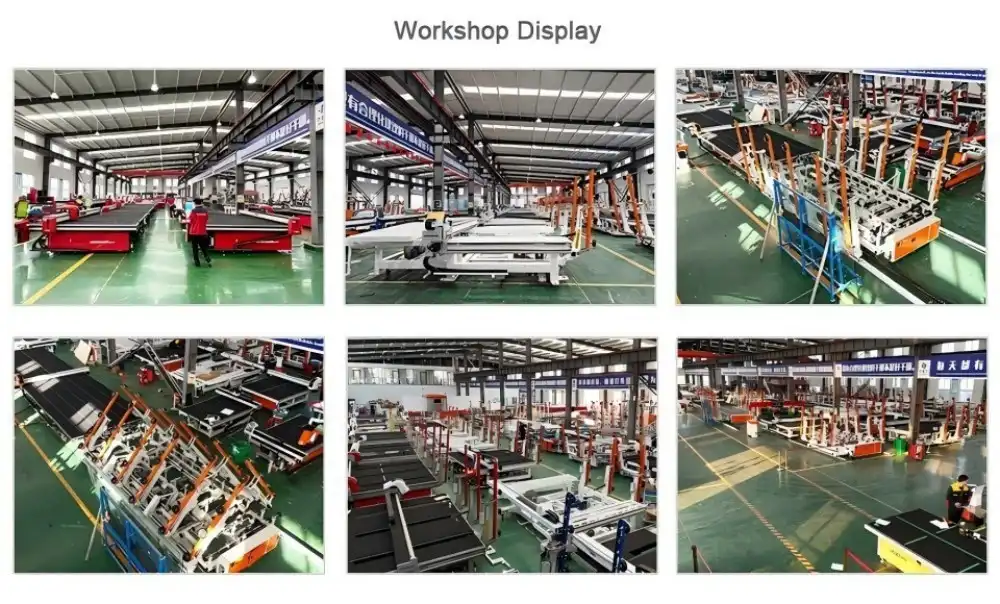

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by glass processors and manufacturers. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment have given us deep insights into the needs of the industry. We're committed to providing high-quality, innovative solutions like the Air Float Glass Loading Table to help our customers stay competitive in an ever-evolving market.

Ready to revolutionize your glass processing operations? Don't hesitate to reach out to us. Our team of experts is ready to help you find the perfect Air Float Glass Loading Table solution for your specific needs. Contact us today at salescathy@sdhuashil.com to learn more about how we can help you achieve new levels of efficiency and productivity in your glass processing operations.

References

1. Johnson, M. (2022). "Advanced Glass Processing Techniques in Modern Manufacturing". Industrial Technology Review.

2. Smith, A. & Brown, L. (2023). "Cost-Benefit Analysis of Automated Glass Handling Systems". Journal of Industrial Engineering.

3. Zhang, Y. et al. (2021). "Innovations in Glass Manufacturing: A Comprehensive Review". Materials Science and Engineering Reports.

4. Thompson, R. (2023). "Workplace Safety in Glass Processing: Current Trends and Future Directions". International Journal of Occupational Safety and Ergonomics.