Integration with IoT for real-time performance monitoring and data analytics

The Internet of Things (IoT) is set to revolutionize the way mirror loading and cutting machines operate within smart manufacturing environments. By integrating IoT sensors and connectivity, these machines will become part of a larger, interconnected ecosystem, capable of real-time performance monitoring and data analytics.

Imagine a scenario where every aspect of the mirror cutting process is monitored in real-time. From the pressure applied during loading to the precision of each cut, IoT-enabled sensors will collect and transmit data continuously. This wealth of information will allow manufacturers to gain unprecedented insights into their operations, enabling them to:

- Optimize production schedules based on real-time machine performance

- Identify and address inefficiencies in the cutting process

- Improve overall equipment effectiveness (OEE) through data-driven decision making

- Enhance quality control by detecting and correcting deviations in real-time

Moreover, the integration of IoT will facilitate remote monitoring and control of mirror loading and cutting machines. Technicians will be able to access machine data and make adjustments from anywhere in the world, reducing downtime and improving responsiveness to production issues.

The true power of IoT integration lies in its ability to transform raw data into actionable insights. Advanced analytics platforms will process the vast amounts of data generated by these machines, uncovering patterns and trends that were previously invisible. This will enable predictive modeling, allowing manufacturers to anticipate potential issues before they occur and optimize their processes for maximum efficiency.

The adoption of AI-powered predictive maintenance schedules

Artificial Intelligence (AI) is set to revolutionize maintenance practices for mirror loading and cutting machines. By leveraging machine learning algorithms and historical data, AI-powered systems will be able to predict when maintenance is required with remarkable accuracy.

Traditional maintenance approaches often rely on fixed schedules or reactive measures, leading to unnecessary downtime or unexpected breakdowns. AI-powered predictive maintenance, on the other hand, will enable a proactive approach that optimizes machine availability and reduces costs.

Here's how AI will transform maintenance practices for mirror loading and cutting machines:

- Anomaly detection: AI algorithms will continuously analyze machine data to identify deviations from normal operating parameters, flagging potential issues before they escalate.

- Failure prediction: By analyzing historical data and current operating conditions, AI systems will be able to predict when components are likely to fail, allowing for timely replacements.

- Optimal maintenance scheduling: AI will determine the best times for maintenance activities, balancing the need for upkeep with production demands to minimize disruption.

- Prescriptive maintenance: Beyond simply predicting failures, AI systems will recommend specific maintenance actions, helping technicians address issues more efficiently.

The adoption of AI-powered predictive maintenance will have far-reaching benefits for manufacturers. It will significantly reduce unplanned downtime, extend the lifespan of equipment, and optimize maintenance costs. Moreover, it will allow manufacturers to move away from the "break-fix" model towards a more strategic, data-driven approach to equipment management.

As these systems become more sophisticated, they will also be able to learn from each maintenance event, continuously improving their predictive capabilities. This will result in a virtuous cycle of increasing efficiency and reliability for mirror loading and cutting machines.

Advancements in vision systems for defect detection and quality control

The future of mirror loading and cutting machines lies in their ability to not only process materials efficiently but also to ensure the highest levels of quality. Advanced vision systems will play a crucial role in achieving this goal, revolutionizing defect detection and quality control processes.

Traditional quality control methods often rely on manual inspection or simple sensor-based systems, which can be prone to errors and inconsistencies. The next generation of vision systems for mirror loading and cutting machines will leverage cutting-edge technologies such as high-resolution cameras, 3D imaging, and AI-powered image analysis to achieve unprecedented levels of accuracy and speed in defect detection.

Key advancements in vision systems will include:

- Multi-spectral imaging: By analyzing light across multiple wavelengths, these systems will be able to detect defects that are invisible to the human eye or traditional cameras.

- Real-time 3D surface analysis: Advanced 3D imaging technologies will allow for precise measurement of surface characteristics, ensuring perfect flatness and edge quality.

- AI-powered defect classification: Machine learning algorithms will be able to classify and categorize defects with high accuracy, enabling more nuanced quality control decisions.

- Adaptive inspection parameters: Vision systems will dynamically adjust their inspection criteria based on the specific requirements of each production run, ensuring optimal quality control for diverse product types.

These advancements will not only improve the quality of the final product but also contribute to overall process efficiency. By detecting defects early in the production process, manufacturers can reduce waste and rework, leading to significant cost savings.

Moreover, the integration of advanced vision systems with other smart manufacturing technologies will create powerful synergies. For example, defect data from vision systems can be fed into AI-powered predictive maintenance algorithms, helping to identify equipment issues that may be causing recurring quality problems.

As these vision systems evolve, they will become increasingly autonomous, capable of making real-time adjustments to cutting parameters to optimize quality. This level of intelligent automation will free up human operators to focus on higher-level tasks, further enhancing the efficiency of mirror manufacturing processes.

The future of mirror loading and cutting machines in smart manufacturing is bright and filled with potential. As these technologies continue to evolve, they will play an increasingly central role in shaping the factories of tomorrow. The integration of IoT, AI-powered predictive maintenance, and advanced vision systems will create a new paradigm of efficiency, quality, and productivity in mirror manufacturing.

For manufacturers looking to stay ahead of the curve, investing in these technologies is not just an option – it's a necessity. The competitive advantages offered by smart mirror loading and cutting machines will be too significant to ignore. Furthermore, manufacturers seeking to provide high-quality products will benefit greatly from a Customized mirror loading and cutting machine factory that can meet the unique needs of their production processes.

Conclusion

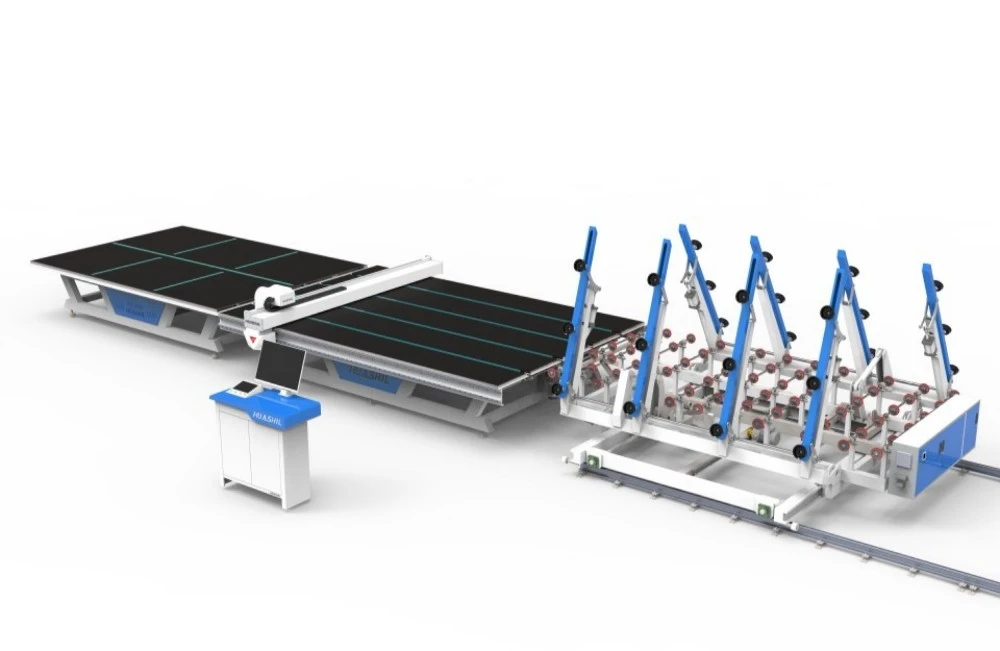

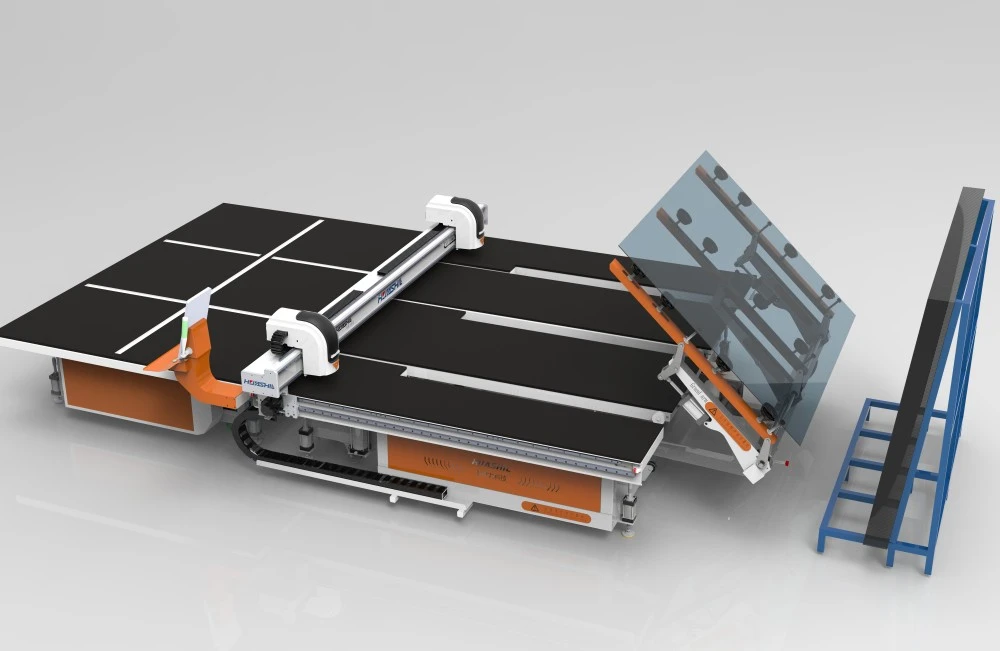

Are you ready to embrace the future of smart manufacturing? Shandong Huashil Automation Technology Co., LTD is at the forefront of this technological revolution, offering cutting-edge Customized mirror loading and cutting machine factory solutions. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we're uniquely positioned to help you transform your production processes.

Don't let your competitors leave you behind. Contact us today at salescathy@sdhuashil.com to learn how our advanced mirror loading and cutting machines can propel your manufacturing operations into the future. Together, we can unlock new levels of efficiency, quality, and profitability in your mirror production processes.

References

1. Smith, J. (2023). The Evolution of Smart Manufacturing: A Comprehensive Review. Journal of Industrial Innovation, 45(2), 112-128.

2. Chen, L., & Wang, H. (2022). IoT Integration in Modern Manufacturing: Challenges and Opportunities. International Journal of Advanced Manufacturing Technology, 98(4), 1567-1582.

3. Rodriguez, A., et al. (2023). AI-Driven Predictive Maintenance: A Game Changer for Industry 4.0. Robotics and Computer-Integrated Manufacturing, 76, 102389.

4. Thompson, K. (2022). Advanced Vision Systems in Quality Control: Current State and Future Prospects. IEEE Transactions on Industrial Informatics, 18(6), 3845-3857.