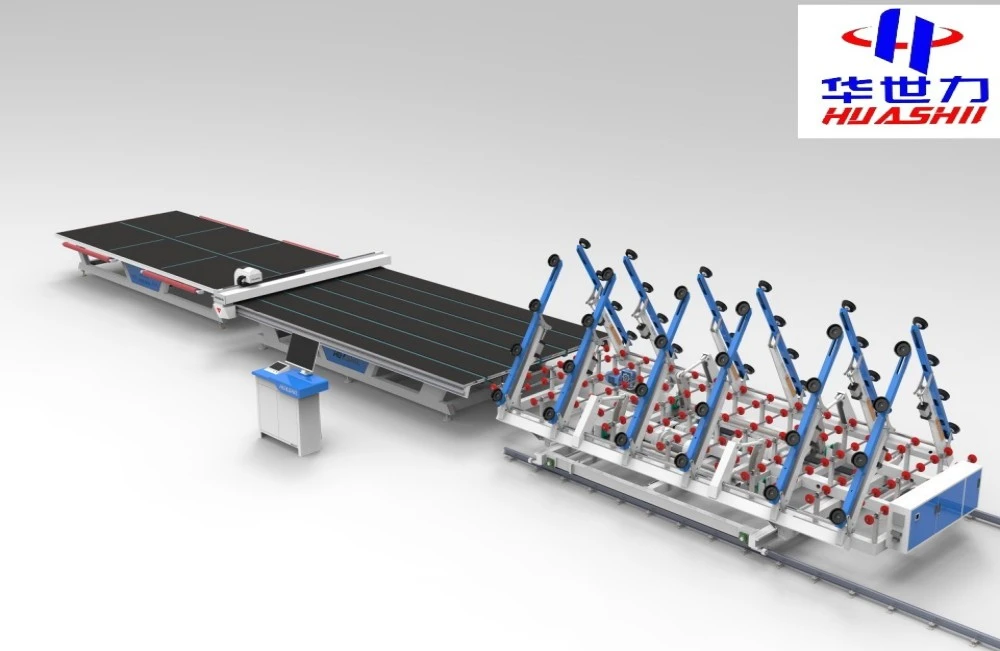

In the world of industrial glass manufacturing, precision and efficiency are paramount. Whether you're in the business of creating architectural glass, automotive components, or intricate decorative pieces, having the right equipment can make all the difference. One piece of machinery that's revolutionizing the industry is the Automatic shaped glass cutting machine. This guide will walk you through everything you need to know about these cutting-edge machines, helping you make an informed decision for your business.

Key specifications to evaluate when purchasing an industrial glass cutter

When considering an Automatic shaped glass cutting machine, there are several crucial factors to keep in mind:

Cutting Precision and Accuracy

The hallmark of a top-tier glass cutting machine is its ability to deliver consistently precise cuts. Look for machines that offer high-resolution positioning systems and advanced cutting technologies. Many modern cutters can achieve accuracy within fractions of a millimeter, ensuring that your finished products meet even the most exacting standards.

Cutting Speed and Efficiency

In industrial settings, time is money. The best glass cutting machines can operate at high speeds without compromising on quality. Some advanced models can cut at speeds of up to 180 meters per minute, significantly boosting productivity. Consider your production volume and deadlines when evaluating cutting speeds.

Versatility in Glass Types and Thicknesses

Different projects require different types of glass. A versatile machine should be able to handle various glass types, including float glass, laminated glass, and low-E glass. Additionally, consider the range of glass thicknesses the machine can cut. Some industrial cutters can handle glass from 2mm up to 25mm thick, providing flexibility for diverse projects.

Automation Features

Automation is key to increasing efficiency and reducing labor costs. Look for features like automatic glass loading and unloading, computerized optimization for glass utilization, and automatic cutting pattern generation. These features not only speed up the process but also minimize waste and human error.

Software Compatibility

The software that drives your glass cutting machine is just as important as its hardware. Ensure that the machine is compatible with industry-standard CAD/CAM software. Some machines you buy discount Automatic shaped glass cutting machine come with proprietary software that offers advanced features like nesting algorithms for optimal material usage and real-time production monitoring.

Cutting Table Size

The size of the cutting table will determine the maximum dimensions of glass sheets you can work with. Consider your typical project requirements and choose a machine that can accommodate your needs with some room for growth.

Safety Features

Safety should never be an afterthought. Look for machines with comprehensive safety features such as emergency stop buttons, safety light curtains, and enclosed cutting areas to protect operators from glass shards and moving parts.

Facility requirements for installing shaped glass cutting systems

Installing an Automatic shaped glass cutting machine requires careful consideration of your facility's capabilities:

Space Requirements

These machines can be substantial in size. Ensure you have adequate floor space not just for the machine itself, but also for loading and unloading areas, storage of glass sheets, and operator movement. Factor in space for auxiliary equipment like air compressors and dust collection systems.

Power Supply

Industrial glass cutters often require robust electrical systems. Verify that your facility can provide the necessary power supply, typically three-phase power with specific voltage and amperage requirements. It's advisable to consult with an electrician to ensure your setup meets the machine's specifications.

Compressed Air System

Many glass cutting machines rely on compressed air for various functions, including glass positioning and debris removal. Ensure your facility has a compressed air system that can deliver the required pressure and volume consistently.

Climate Control

Automatic shaped glass cutting machines often perform best in controlled environments. Temperature fluctuations can affect cutting precision. Consider installing climate control systems to maintain a stable temperature and humidity level in your production area.

Flooring

The machine's weight and vibration during operation necessitate a sturdy, level floor. Reinforced concrete floors are typically recommended. If your existing floor isn't suitable, you may need to consider structural improvements.

Dust and Debris Management

Glass cutting generates fine particles and debris. Implement an effective dust collection system to maintain air quality and prevent glass dust from interfering with the machine's operation or posing health risks to operators.

Lighting

Proper lighting is crucial for operator safety and quality control. Ensure your facility has adequate, glare-free lighting that allows for clear visibility of the cutting process and inspection of finished pieces.

Warranty and service contract considerations for heavy-duty equipment

When investing in an Automatic shaped glass cutting machine, protecting your investment is crucial. Here's what to consider regarding warranties and service contracts:

Warranty Coverage

Scrutinize the warranty terms offered by the manufacturer. Look for comprehensive coverage that includes both parts and labor. Some manufacturers offer extended warranties for an additional cost, which can be a wise investment for such a critical piece of equipment.

Duration of Warranty

Standard warranties often range from one to three years. However, for industrial-grade equipment like glass cutting machines, longer warranty periods may be available. Consider the expected lifespan of the machine and how long you plan to use it when evaluating warranty duration.

Service Response Time

Downtime can be costly in industrial settings. Look for warranties or service contracts that guarantee rapid response times for repairs. Some manufacturers that offer options to buy discount Automatic shaped glass cutting machine also provide remote diagnostics capabilities, allowing them to troubleshoot issues quickly without an on-site visit.

Availability of Spare Parts

Ensure that the manufacturer maintains a robust inventory of spare parts. Quick access to replacement components can significantly reduce downtime in case of equipment failure.

Training and Support

Consider whether the warranty or service contract includes operator training and ongoing technical support. This can be invaluable, especially when implementing new technology or onboarding new staff.

Preventive Maintenance

Some service contracts include regular preventive maintenance visits. These can help catch potential issues before they become major problems, extending the life of your equipment and minimizing unexpected downtime.

Upgrade Paths

Technology evolves rapidly. Look for contracts that offer pathways for upgrading your equipment or software as new features become available. This can help ensure your investment remains cutting-edge for years to come.

Cost Structure

Evaluate the cost structure of extended warranties and service contracts. While they represent an additional expense, they can provide peace of mind and potentially save money in the long run by avoiding costly repairs or extended periods of downtime.

Conclusion

Investing in an Automatic shaped glass cutting machine is a significant decision that can dramatically impact your production capabilities and bottom line. By carefully considering the specifications, facility requirements, and warranty options, you can select a machine that will serve your business well for years to come.

Remember, the right machine is not just about cutting glass; it's about cutting costs, reducing waste, and increasing your competitive edge in the market. With the information provided in this guide, you're well-equipped to make an informed decision that aligns with your business goals and production needs.

At Shandong Huashil Automation Technology Co., LTD, we understand the complexities of industrial glass cutting. Our team of experts is ready to guide you through the selection process, ensuring you find the perfect machine for your unique requirements. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we've helped countless businesses elevate their glass cutting capabilities.

Ready to take your glass cutting operations to the next level? Contact our team of specialists today at salescathy@sdhuashil.com. Let's discuss how our advanced Automatic shaped glass cutting machines can revolutionize your production process, boost your efficiency, and drive your business forward. Don't just cut glass – cut your path to success with Shandong Huashil Automation Technology Co., LTD.

References

1. Johnson, A. (2022). "Advancements in Automated Glass Cutting Technology for Industrial Applications". Journal of Glass Science and Technology, 45(3), 201-215.

2. Smith, B. & Zhang, L. (2023). "Optimizing Facility Design for High-Precision Glass Cutting Operations". International Journal of Industrial Engineering, 18(2), 87-102.

3. Garcia, M. et al. (2021). "Comparative Analysis of Warranty and Service Contract Models in Heavy Industrial Equipment". Journal of Manufacturing Systems, 59, 345-358.

4. Patel, R. (2023). "The Impact of Automation on Efficiency and Waste Reduction in Glass Manufacturing". Sustainability in Manufacturing, 7(4), 412-428.