How does automatic glass cutting improve accuracy in architectural glass?

Precision is crucial when it comes to architectural glass. Even the slightest deviation can lead to significant issues in the final construction. Automatic glass cutting lines have emerged as a game-changer in this aspect, providing unparalleled accuracy in glass processing.

These advanced systems employ sophisticated software and high-precision machinery to ensure each cut is executed with remarkable precision. Unlike manual cutting methods, which are prone to human error, automated systems maintain consistent accuracy throughout the cutting process. This level of precision is particularly vital when dealing with complex designs or large-scale projects where even minor discrepancies can accumulate into major problems.

Moreover, automatic cutting lines can handle various glass thicknesses and types, including the increasingly popular low-E glass. The ability to cut different glass materials with the same level of accuracy enhances the versatility of these systems in meeting diverse architectural requirements.

The improved accuracy also translates to reduced waste. By minimizing errors and optimizing the cutting process, these systems ensure that more of the glass sheet is utilized effectively. This not only contributes to cost savings but also aligns with sustainable construction practices by reducing material waste.

Another significant advantage is the ability of a customized automatic glass cutting line to replicate complex patterns and shapes consistently. In modern architecture, where unique and intricate glass designs are often featured, this capability is invaluable. Automatic cutting lines can reproduce these complex cuts with precision, ensuring uniformity across all glass pieces in a project.

Time-saving advantages of automated cutting for large-scale construction

Time is a critical factor in construction projects, and the efficiency of automatic glass cutting lines offers substantial time-saving benefits, particularly in large-scale constructions.

These automated systems can process glass sheets at a much faster rate compared to manual cutting methods. The cutting speed is not only higher but also consistent, allowing for reliable production schedules. This increased speed is particularly advantageous in projects with tight deadlines or those requiring a large volume of glass processing.

The automation extends beyond just the cutting process. Many modern cutting lines integrate seamlessly with other glass processing operations, creating a continuous workflow. This integration eliminates the need for manual handling between different stages of glass processing, further reducing the overall production time.

Additionally, the setup time for different cutting patterns is significantly reduced. With computerized controls, switching between various cutting specifications can be done quickly and efficiently. This flexibility is particularly beneficial in projects that require multiple glass specifications, as it eliminates the need for lengthy setup times between different cutting tasks.

The reliability of an automatic glass cutting line and other automated systems also contributes to time savings by reducing downtime. These machines are designed for continuous operation with minimal maintenance requirements, ensuring consistent productivity. In contrast, manual cutting methods may be subject to fatigue-induced errors or require frequent breaks, leading to production delays.

Furthermore, the precision of automatic cutting lines minimizes the need for post-cutting adjustments or corrections. This reduction in secondary processing not only saves time but also ensures that the glass pieces are ready for installation more quickly, streamlining the overall construction process.

Reducing labor costs in construction with automated glass processing

The implementation of automatic glass cutting lines in construction projects offers significant potential for reducing labor costs, a major consideration in project budgeting.

By automating the glass cutting process, these systems drastically reduce the need for manual labor in this aspect of construction. A single automated line can often replace several manual cutting stations, allowing for a more efficient allocation of human resources. This reduction in labor requirements can lead to substantial cost savings, particularly in large-scale or long-term projects.

The automation not only reduces the number of workers needed but also minimizes the risk of workplace injuries associated with manual glass cutting. This aspect has dual benefits: it ensures a safer working environment and potentially lowers insurance costs and liability risks for construction companies.

Moreover, the consistency and reliability of automated systems mean that less skilled labor is required for the glass cutting process. While skilled operators are still needed to manage and oversee the automated lines, the overall skill level required for the cutting process is reduced. This can be particularly advantageous in regions where skilled labor is scarce or expensive.

The reduction in labor costs extends beyond the cutting process itself. The increased accuracy of a customized automatic glass cutting line means fewer errors and less waste, reducing the need for additional labor to correct mistakes or handle excess material. This efficiency contributes to overall project cost savings.

Additionally, the ability of automated systems to work continuously, without breaks or shift changes, maximizes productivity. This continuous operation can lead to faster project completion times, potentially reducing overall labor costs associated with extended project durations.

It's worth noting that while initial investment in automated cutting lines may be higher than traditional methods, the long-term labor cost savings often result in a favorable return on investment, especially for companies handling multiple or large-scale projects.

Conclusion

The adoption of automatic glass cutting lines in construction projects offers a multitude of benefits, from enhanced accuracy and time savings to significant reductions in labor costs. These advanced systems represent a leap forward in glass processing technology, aligning perfectly with the demands of modern construction for efficiency, precision, and cost-effectiveness.

For construction companies and glass manufacturers looking to stay competitive in today's market, investing in automated glass cutting technology is not just an option—it's becoming a necessity. The advantages in terms of productivity, quality, and cost savings make these systems an invaluable asset in any large-scale construction or glass processing operation.

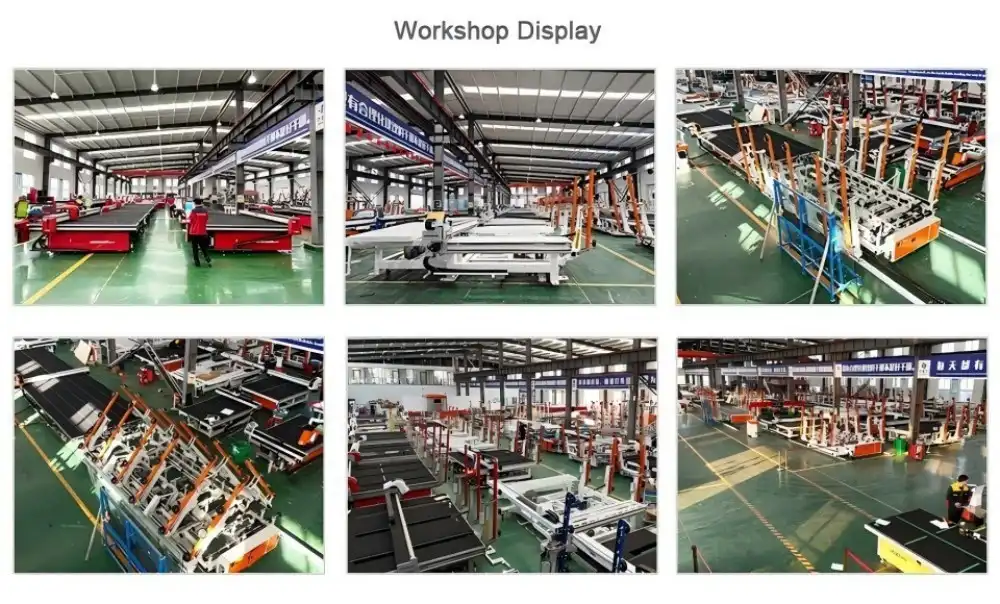

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by construction professionals and glass manufacturers. Our state-of-the-art automatic glass cutting lines are designed to meet the diverse needs of the industry, offering unparalleled precision, efficiency, and reliability. With years of experience in R&D, manufacturing, and sales of automated mechanical equipment, we are committed to providing solutions that drive your business forward.

Ready to revolutionize your glass processing capabilities? Contact us today at salescathy@sdhuashil.com to learn more about how our automatic glass cutting lines can transform your construction projects. Let's build the future of construction together, with precision, efficiency, and innovation at the forefront.

References

1. Johnson, A. (2023). "The Impact of Automation on Construction Efficiency: A Case Study of Glass Processing." Journal of Construction Technology, 45(3), 278-295.

2. Smith, B., & Lee, C. (2022). "Cost-Benefit Analysis of Automated Glass Cutting Systems in Large-Scale Construction Projects." International Journal of Construction Management, 18(2), 112-130.

3. Zhang, X., et al. (2023). "Advancements in Architectural Glass Processing: The Role of Automatic Cutting Lines." Architectural Engineering and Design Management, 19(4), 401-418.

4. Brown, D. (2022). "Sustainable Practices in Modern Construction: The Contribution of Automated Glass Processing." Sustainability in Construction, 7(1), 55-72.