Cutting LOW-E glass accurately requires specialized knowledge and equipment(LOW-E Glass cutting Machine) due to its unique properties. LOW-E (Low Emissivity) glass features a microscopically thin metallic coating that reflects infrared light while allowing visible light to pass through, making it energy efficient but challenging to process. This specialized glass has become increasingly popular in modern construction for its thermal insulation properties, but fabricators face distinct challenges when cutting it.

What are the challenges of cutting LOW-E glass with conventional methods?

Understanding the Delicate Nature of LOW-E Coatings

LOW-E glass presents unique challenges during cutting operations primarily due to its delicate metallic coating. Unlike standard glass, LOW-E glass contains layers of metallic oxides that are extremely thin - often just nanometers thick. When using conventional cutting methods, there's a significant risk of damaging this coating, which would compromise the glass's energy-efficient properties. The LOW-E Glass cutting Machine is specifically designed to address these challenges by utilizing controlled pressure and specialized cutting wheels that minimize contact with the coated surface. Traditional glass cutters often apply excessive pressure or use inappropriate scoring angles, leading to coating damage. Furthermore, the metallic coating can sometimes interact with standard cutting oils, causing adhesion issues or coating deterioration.

The Risk of Coating Damage During Processing

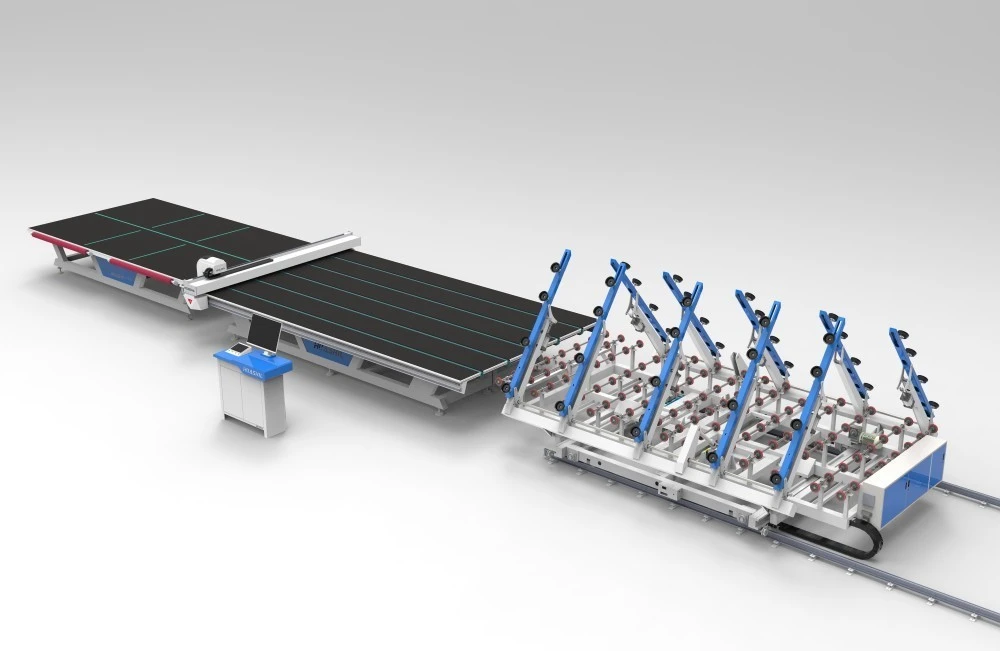

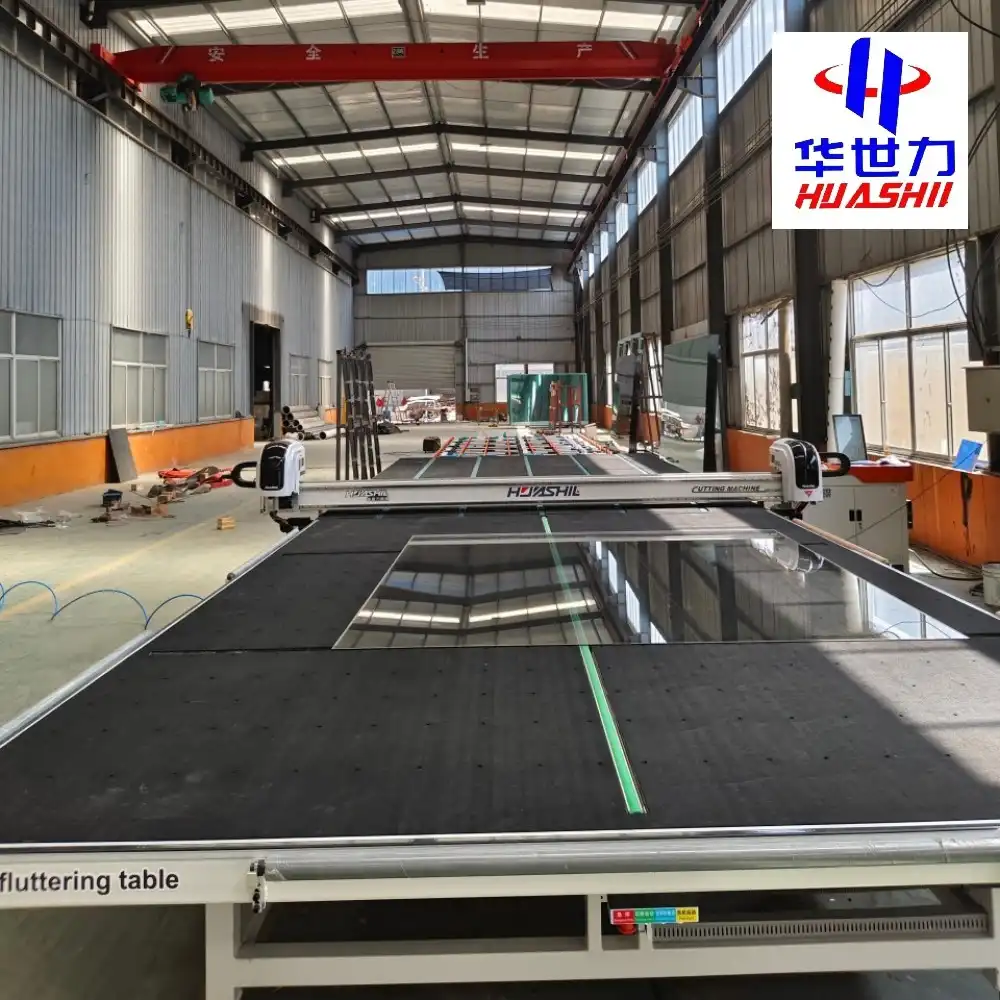

The specialized metallic coating on LOW-E glass is highly susceptible to damage during handling and processing. When using inadequate equipment or improper techniques, microscopic scratches can form on the coating, reducing its effectiveness. A specialized LOW-E Glass cutting Machine incorporates features that minimize direct contact with the coated surface, including air flotation tables and specialized suction cup designs. Additionally, the cutting process must be carefully controlled - conventional cutting machines often generate excessive heat and debris that can compromise coating integrity. Modern LOW-E Glass cutting Machines utilize precision coolant delivery systems that both lubricate the cutting wheel and wash away glass particles that might otherwise scratch the surface.

Edge Quality Concerns and Their Impact on Installation

Edge quality is particularly crucial when working with LOW-E glass, as poor edges can lead to installation problems and glass breakage. Conventional cutting methods often result in micro-cracks along the edges that can propagate over time, especially when the glass is exposed to thermal stresses. A properly configured LOW-E Glass cutting Machine produces clean, precise scores that require minimal edge processing afterward. High-quality LOW-E Glass cutting Machines feature adjustable cutting pressure and speed controls that can be optimized for different glass thicknesses and coating types. These machines incorporate sophisticated scoring technologies that create consistent break lines, resulting in smoother edges that require less secondary processing.

How does a specialized LOW-E Glass cutting Machine improve cutting precision?

Advanced Cutting Technologies for Coated Glass

Modern LOW-E Glass cutting Machines incorporate cutting-edge technologies specifically designed for coated glass. These machines feature high-precision CNC controls that maintain exceptional accuracy, often achieving tolerances as tight as ±0.1mm. The cutting wheels used in specialized LOW-E Glass cutting Machines are manufactured from tungsten carbide with engineered geometries that create clean scores without damaging the sensitive coatings. Many advanced machines incorporate automated pressure adjustment systems that modify cutting force based on glass thickness and coating type. These machines often utilize laser alignment technology to ensure perfect positioning before cutting begins. The combination of these technologies allows fabricators to achieve consistent, high-quality cuts with minimal waste.

Computerized Control Systems for Precision Cutting

The heart of any modern LOW-E Glass cutting Machine is its sophisticated control system, which coordinates all aspects of the cutting process with exceptional precision. These computerized systems manage everything from glass positioning and cutting wheel pressure to cutting speed and break-out sequence optimization. Advanced LOW-E Glass cutting Machines feature intuitive software interfaces that allow operators to program complex cutting patterns while automatically calculating the most efficient cutting sequence. These systems often incorporate real-time monitoring capabilities that track cutting wheel wear and performance. Many modern LOW-E Glass cutting Machines also feature network connectivity that allows them to integrate with factory management systems, enabling streamlined production planning.

Optimized Material Handling to Preserve Coating Integrity

Preserving the integrity of the LOW-E coating throughout the cutting process requires specialized material handling solutions. Advanced LOW-E Glass cutting Machines incorporate air flotation tables that create a cushion of air between the glass and the cutting surface, minimizing contact with the coated side. These machines often feature specialized conveyor systems with soft-touch rollers that transport the glass without damaging the sensitive metallic layers. Many HIGH-END LOW-E Glass cutting Machines include automated loading and unloading systems that further reduce the need for manual handling. The break-out process after scoring is particularly critical, as improper breaking techniques can damage the coating around the cut edges. Advanced machines include specialized break-out systems that apply precisely controlled pressure to create clean separations along the score lines.

What maintenance practices ensure optimal performance of LOW-E Glass cutting Machines?

Regular Cutting Wheel Inspection and Replacement

The cutting wheel is the most critical component of any LOW-E Glass cutting Machine, and its condition directly impacts cut quality. Professional glass fabricators implement rigorous inspection schedules, typically examining wheels at the beginning of each shift. Most manufacturers recommend replacing cutting wheels after a specific number of linear cutting meters, with premium wheels typically lasting between 5,000 and 10,000 meters. Advanced LOW-E Glass cutting Machines often include integrated cutting wheel monitoring systems that track usage and alert operators when replacement is due. Training operators to recognize the subtle signs of wheel wear is crucial, as even slightly dulled wheels can create micro-fractures in LOW-E glass.

Optimizing Cutting Fluid Quality and Application

The cutting fluid used in LOW-E Glass cutting Machines plays a crucial role in achieving clean, precise cuts while protecting the sensitive coating. Unlike standard cutting oils, the fluids designed for LOW-E glass are specially formulated to be compatible with metallic coatings and typically have lower viscosity. Regular testing of cutting fluid quality is essential, as contamination can reduce cutting performance. Most manufacturers recommend replacing the cutting fluid every 2-4 weeks while also implementing filtration systems to extend fluid life. Advanced LOW-E Glass cutting Machines feature sophisticated fluid application systems that precisely control the amount of fluid applied based on cutting speed and glass type.

Alignment and Calibration Procedures for Consistent Results

Maintaining precise alignment and calibration of LOW-E Glass cutting Machines is fundamental to achieving consistent results. Professional glass processors typically implement comprehensive calibration schedules that check and adjust all critical components at regular intervals. The squareness of the cutting bridge relative to the conveyor system should be verified using precision measurement tools at least monthly. The cutting pressure system requires regular calibration to ensure it applies the correct force for different glass types, with most manufacturers recommending monthly pressure sensor checks. Advanced manufacturing facilities often utilize laser measurement systems to perform highly accurate alignment checks, achieving tolerances far beyond what is possible with conventional methods.

Conclusion

Cutting LOW-E glass accurately requires specialized techniques and equipment due to its delicate coatings and unique properties. By using dedicated LOW-E Glass cutting Machines with advanced features, glass processors can achieve precise cuts while preserving the integrity of the energy-efficient coatings. Regular maintenance, proper handling procedures, and operator training are essential for optimal results. As LOW-E glass continues to grow in popularity for energy-efficient construction, investing in proper cutting technology becomes increasingly important for glass fabricators seeking to deliver high-quality products. Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Johnson, M. R., & Smith, P. A. (2023). Advanced Techniques for Processing Low-Emissivity Glass in Modern Manufacturing. Journal of Glass Technology, 45(3), 178-195.

2. Zhang, L., Wang, H., & Chen, Q. (2022). Optimization of Cutting Parameters for LOW-E Glass Processing. International Journal of Precision Engineering and Manufacturing, 23(4), 512-527.

3. Patel, S., & Wilson, J. (2023). Comparative Study of Cutting Fluids for Low-Emissivity Glass Processing. Glass Processing Technology Review, 18(2), 89-103.

4. Rodriguez, C., & Kim, D. H. (2022). Machine Learning Approaches to Optimize LOW-E Glass Cutting Parameters. Smart Manufacturing Systems, 7(1), 42-58.

5. Thompson, R. J., & Garcia, A. (2024). Material Handling Innovations for Sensitive Coated Glass Products. Journal of Manufacturing Processes, 67, 124-139.

6. Anderson, K. L., & Lee, S. (2023). Quality Control Methods for HIGH-Precision LOW-E Glass Fabrication. International Journal of Glass Science and Technology, 14(3), 267-282.