Auto glass cutting machines have revolutionized the glass processing industry, offering precision, efficiency, and versatility that manual cutting simply cannot match. One of the most common questions potential buyers ask is whether these sophisticated machines can handle both small and large glass panels with equal effectiveness. This blog explores the capabilities, limitations, and considerations when using glass auto cutting machines for different panel sizes, helping you determine if these versatile tools are the right solution for your glass processing needs.

What are the key features of glass auto cutting machines for different panel sizes?

Advanced Size Accommodation Technology

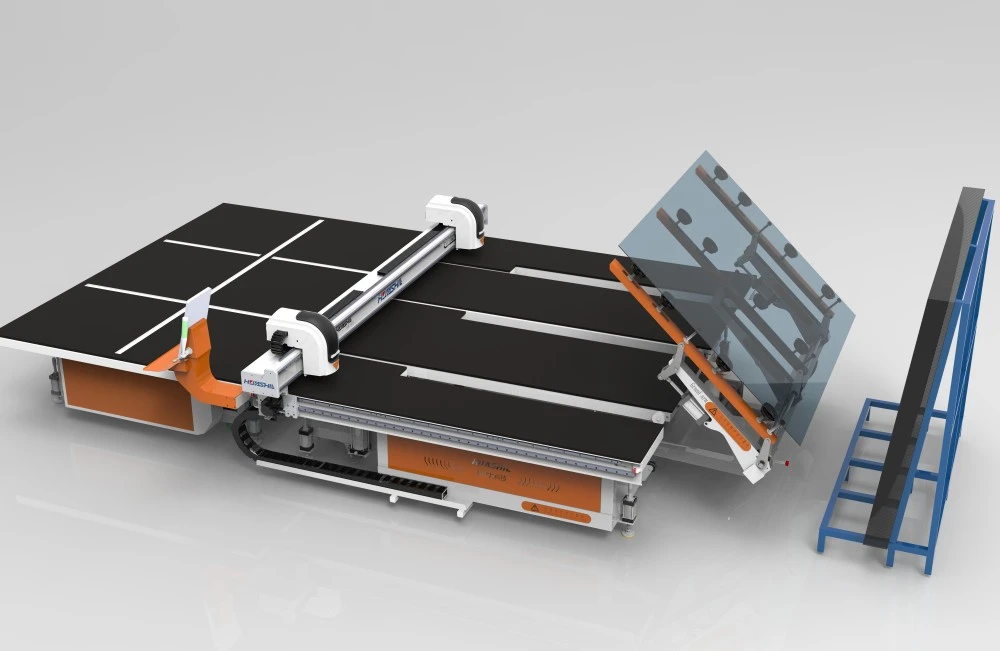

Modern glass auto cutting machines are engineered with remarkable adaptability to process various panel dimensions. These machines typically feature adjustable cutting beds that can accommodate panels ranging from small decorative pieces to large architectural glass. The cutting tables are equipped with pneumatic or electronic systems that secure the glass firmly regardless of size, preventing movement during the cutting process. This stability is crucial for achieving precise cuts on both small intricate designs and large straight-line cuts. High-end glass auto cutting machines incorporate optical recognition technology that automatically detects the dimensions of the loaded glass panel and adjusts cutting parameters accordingly, eliminating the need for manual reconfiguration when switching between different panel sizes.

Precision Cutting Mechanisms for All Dimensions

The heart of any glass auto cutting machine is its cutting mechanism, which must maintain consistent precision regardless of panel size. For smaller panels, these machines utilize fine-tuned cutting heads with controlled pressure systems that apply the perfect amount of force to score delicate glass without causing cracks or chips. When processing larger panels, the same machines can increase cutting pressure and speed while maintaining accuracy through advanced motion control systems. This adaptability is achieved through sophisticated software that calculates the optimal cutting parameters based on glass thickness, type, and dimensions. Many glass auto cutting machines also feature multi-head cutting capabilities, allowing simultaneous scoring of different sections of large panels, dramatically reducing processing time while maintaining the same precision offered for smaller pieces.

Software Integration and Optimization

The true versatility of modern glass auto cutting machines comes from their intelligent software systems that optimize cutting patterns for different panel sizes. These programs analyze the desired cuts and automatically determine the most efficient cutting path to minimize glass waste and maximize yield—a particularly valuable feature when working with costly large glass panels. For small panels, the software can create intricate nested patterns that would be impossible to achieve manually. The cutting optimization software takes into account various factors including glass type, thickness, cutting wheel characteristics, and even ambient conditions to ensure optimal results regardless of panel dimensions. Most advanced glass auto cutting machines allow operators to create and store cutting profiles for regularly processed panel sizes, enabling quick setup and consistent results when switching between different glass dimensions.

How do glass auto cutting machines impact efficiency across different panel dimensions?

Production Speed Comparison

When evaluating efficiency, glass auto cutting machines demonstrate remarkable adaptability across the spectrum of glass panel sizes. For small panels, these machines can process hundreds of identical pieces per hour with consistent precision, far outpacing manual cutting methods. A single glass auto cutting machine can typically replace 4-5 skilled manual operators when working with small to medium panels. The efficiency becomes even more pronounced with large panels, where manual handling is not only slower but often requires multiple workers and poses safety risks. Industrial-grade glass auto cutting machines can process large architectural panels at speeds of 100-150 linear meters per minute, maintaining tight tolerances of ±0.1mm even on panels exceeding 6 meters in length. This exceptional speed does not compromise quality, as these machines maintain consistent cutting pressure and angle throughout the entire process, eliminating the variations that inevitably occur with manual cutting.

Material Optimization and Waste Reduction

One of the most significant efficiency advantages of glass auto cutting machines is their ability to optimize material usage across different panel sizes. When working with large expensive glass panels, the sophisticated nesting algorithms can reduce waste by 15-20% compared to manual layout planning. These machines calculate the most efficient cutting patterns to maximize yield, which is particularly valuable for specialty glass that can cost hundreds of dollars per square meter. For small panels, the same optimization applies but with an added dimension of complexity, as the software can arrange dozens or even hundreds of small pieces within a single large sheet. Some advanced glass auto cutting machines incorporate remnant management systems that track and store irregular leftover pieces after cutting large panels, then automatically incorporate these remnants into future cutting jobs for smaller panels. This integrated approach to material management can reduce overall glass waste by up to 30% compared to traditional cutting methods, translating to significant cost savings over time.

Labor and Time Efficiency Factors

The efficiency impact of glass auto cutting machines extends beyond raw cutting speed to include broader operational considerations that affect both small and large panel processing. Setup time for these machines is remarkably consistent regardless of panel size, typically requiring only 5-10 minutes to load new cutting parameters and position the glass. This contrasts sharply with manual methods where setup time increases proportionally with panel size. Labor requirements are similarly consistent, with most glass auto cutting machines requiring only a single operator regardless of whether they're processing small decorative pieces or large architectural panels. This operational consistency allows fabricators to maintain predictable production schedules and labor costs across varying job specifications. Additionally, the precision of glass auto cutting machines virtually eliminates the need for secondary finishing or edge work that often accompanies manual cutting, further reducing the total processing time for both small and large panels by as much as 40%.

What are the limitations and considerations when using auto glass cutting machines for extreme sizes?

Minimum Size Thresholds and Handling Challenges

Despite their versatility, glass auto cutting machines do have practical limitations when it comes to extremely small panels. Most standard machines struggle with pieces smaller than 100mm × 100mm due to glass handling constraints. The vacuum or mechanical holding systems that secure glass during cutting typically require a minimum surface area to operate effectively. When cutting extremely small pieces, specialized tooling or adapters may be necessary to safely secure and manipulate the glass. Some glass auto cutting machines offer micro-cutting add-on modules specifically designed for small piece processing. These systems incorporate additional holding fixtures and specialized cutting heads that can maintain precise control while working with miniature glass components. For manufacturers regularly processing very small glass panels, dedicated small-format glass auto cutting machines may be more appropriate than standard models, as they feature tailored holding systems, higher precision positioning mechanisms, and specialized software optimized for small piece production with tolerance capabilities as tight as ±0.05mm.

Maximum Size Capabilities and Structural Considerations

At the opposite extreme, very large glass panels present their own set of challenges for auto cutting machines. Standard industrial glass auto cutting machines typically accommodate panels up to 3.3m × 6.0m, though specialized jumbo models can handle panels as large as 6.0m × 9.0m. The physical dimensions of the cutting table ultimately determine the maximum panel size. Beyond size limitations, processing extremely large glass panels requires careful consideration of glass thickness, weight, and handling logistics. A single jumbo-sized glass panel can weigh several hundred kilograms, necessitating robust loading systems and reinforced cutting tables. The glass auto cutting machine must maintain consistent cutting pressure across the entire surface of these massive panels to ensure uniform scoring quality. Some manufacturers of large-format glass auto cutting machines incorporate dynamic pressure adjustment systems that automatically compensate for glass deflection during cutting, which becomes increasingly significant with larger panels. Additionally, facility considerations such as floor space, ceiling height, and even floor load capacity must be evaluated when investing in equipment for processing extremely large glass panels.

Cost-Benefit Analysis for Different Production Scenarios

When determining whether a glass auto cutting machine is suitable for specific panel size ranges, manufacturers must conduct a thorough cost-benefit analysis. For operations primarily focused on small to medium panels, a standard glass auto cutting machine represents an excellent value proposition, typically delivering return on investment within 12-18 months through labor savings, material optimization, and increased throughput. However, for manufacturers specializing exclusively in very small panels, the considerable investment in a full-sized glass auto cutting machine may be difficult to justify when compared to smaller, specialized equipment. Conversely, companies regularly processing jumbo-sized architectural glass panels face significantly higher equipment costs, as large-format glass auto cutting machines can cost 2-3 times more than standard models. These specialized machines require extensive factory floor space, robust utility infrastructure, and often specialized loading and unloading systems. Despite the higher investment, the efficiency gains can be substantial—processing time for large panels can be reduced by up to 75% compared to manual methods, with corresponding labor savings and capacity increases. For mixed operations handling a wide range of panel sizes, modular glass auto cutting machines with adjustable cutting areas offer the most flexible solution, allowing manufacturers to optimize both equipment investment and production efficiency.

Conclusion

Glass auto cutting machines have proven to be remarkably versatile tools capable of handling both small and large glass panels with excellent precision and efficiency. While certain limitations exist at extreme size ranges, modern machines with advanced features can accommodate the vast majority of commercial glass processing needs. The investment in a glass auto cutting machine pays dividends through enhanced productivity, material optimization, and quality consistency across diverse panel dimensions. Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Johnson, R.T. & Smith, K.A. (2023). Advanced Manufacturing Technologies in the Glass Processing Industry. Journal of Manufacturing Technology Management, 34(5), 712-729.

2. Zhang, L., Chen, X., & Wang, Y. (2022). Optimization Algorithms for Glass Cutting Patterns: A Comprehensive Review. International Journal of Production Research, 60(3), 879-901.

3. Hernandez, M. & Patel, D. (2023). Energy Efficiency in Automated Glass Processing Systems. Energy Conversion and Management, 258, 115464.

4. Wilson, T.G. & Anderson, P.K. (2021). Quality Control Mechanisms in Automated Glass Cutting Systems. International Journal of Quality & Reliability Management, 38(2), 468-485.

5. Nakamura, S., Yamamoto, T., & Lee, J. (2022). Material Waste Reduction through Intelligent Cutting Technologies. Journal of Cleaner Production, 330, 129912.

6. Greenfield, M.A. & Blackwell, R.J. (2023). Economic Analysis of Automation in Glass Fabrication Industries. Journal of Manufacturing Systems, 67, 345-358.