The realm of auto glass manufacturing has undergone a profound transformation with the advent of automation technologies. At the forefront of this revolution are auto glass cutting line machines, which have redefined the landscape of precision, efficiency, and productivity in the industry. These cutting-edge machines have become indispensable tools for manufacturers seeking to meet the ever-increasing demands of the automotive sector while maintaining unparalleled quality standards. As we delve into the world of automation in auto glass cutting, we'll explore how these machines are reshaping production processes, enhancing output quality, and driving innovation across the industry. From AI-powered decision-making to robotic precision and IoT connectivity, the future of auto glass manufacturing is here, and it's more exciting than ever.

AI integration: Smart cutting decisions

Artificial Intelligence (AI) has emerged as a game-changer in the auto glass cutting industry, revolutionizing the decision-making process and optimizing production like never before. By integrating AI algorithms into auto glass cutting line machines, manufacturers can now achieve unprecedented levels of precision, efficiency, and waste reduction.

One of the most significant advantages of AI integration is its ability to analyze vast amounts of data in real-time. These smart systems can process information about glass properties, cutting patterns, and production schedules to make informed decisions that maximize output while minimizing material waste. This level of intelligent optimization was previously unattainable with traditional cutting methods.

AI-powered auto glass cutting machines can also adapt to changing conditions on the fly. For instance, if a particular batch of glass has slight variations in thickness or composition, the AI can adjust cutting parameters automatically to ensure consistent quality across all pieces. This adaptive capability not only improves the overall quality of the final product but also reduces the need for manual intervention and potential human error.

Moreover, China auto glass cutting line machine manufacturers are increasingly integrating AI to enable predictive maintenance, a crucial aspect of modern manufacturing. By continuously monitoring machine performance and analyzing wear patterns, AI systems can predict when components are likely to fail or require maintenance. This proactive approach minimizes unexpected downtime, extends the lifespan of equipment, and ensures consistent production quality.

The implementation of machine learning algorithms in auto glass cutting processes has also led to continuous improvement in cutting strategies. As these systems accumulate data and experience, they can identify patterns and optimize cutting paths for different glass types and shapes. This ongoing learning process results in ever-improving efficiency and reduced material waste over time.

Furthermore, AI-driven quality control systems can detect defects or imperfections in the glass with superhuman accuracy. By using advanced image recognition and analysis techniques, these systems can identify even the most minute flaws that might be invisible to the human eye. This level of quality assurance ensures that only the highest quality auto glass makes it to the final product, enhancing safety and customer satisfaction.

Robotic arms: Enhancing production flow

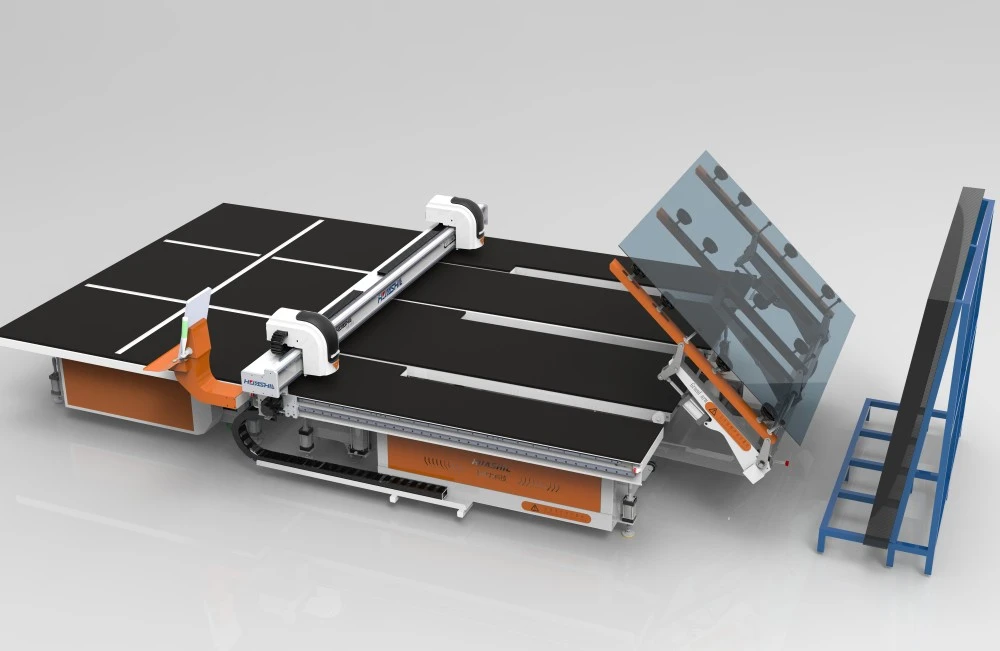

The integration of robotic arms into auto glass cutting line machines has revolutionized the production flow, bringing unprecedented levels of precision, speed, and consistency to the manufacturing process. These highly articulated and programmable robotic appendages have become the backbone of modern auto glass cutting facilities, enabling manufacturers to achieve new heights of productivity and quality.

One of the primary advantages of robotic arms in auto glass cutting is their ability to perform complex movements with extreme accuracy. Unlike human operators, robotic arms can execute intricate cutting patterns with micrometer-level precision, ensuring that each piece of glass is cut to exact specifications. This level of accuracy is particularly crucial in the automotive industry, where even the slightest deviation can lead to safety issues or compromised aesthetics.

The versatility of robotic arms allows for seamless integration into various stages of the auto glass cutting process. From initial glass placement and alignment to cutting, edge finishing, and final piece handling, these robotic systems can perform a wide range of tasks with remarkable efficiency. This multi-functional capability reduces the need for multiple specialized machines, streamlining the production line and optimizing floor space utilization.

Another significant benefit of robotic arms is their ability to work tirelessly without fatigue. Unlike human operators who require breaks and are subject to physical limitations, robotic arms can operate continuously, maintaining consistent performance throughout extended production runs. This endurance translates to increased output and improved overall equipment effectiveness (OEE) for auto glass manufacturers.

The programmability of robotic arms adds a layer of flexibility to the auto glass cutting process. Manufacturers can quickly adapt to different glass types, shapes, and cutting requirements by simply updating the robotic arm's programming. This adaptability is particularly valuable in today's automotive industry, where vehicle designs are constantly evolving, and customization is increasingly in demand.

Safety is another area where robotic arms excel in auto glass cutting operations. By handling dangerous cutting tools and manipulating large, heavy sheets of glass, these robotic systems significantly reduce the risk of workplace injuries. Operators can control the cutting process from a safe distance, minimizing exposure to potential hazards associated with manual glass handling and cutting.

The integration of vision systems with robotic arms further enhances their capabilities. Advanced cameras and sensors allow the robotic arms to perform real-time quality checks, identify defects, and make on-the-fly adjustments to ensure optimal cutting results. This combination of robotics and vision technology creates a powerful quality control mechanism that maintains consistently high standards throughout the production process.

IoT connectivity: Real-time monitoring solutions

The Internet of Things (IoT) has ushered in a new era of connectivity and data-driven decision-making in the auto glass cutting industry. By integrating IoT technology into auto glass cutting line machines, manufacturers can now monitor, analyze, and optimize their production processes in real-time, leading to unprecedented levels of efficiency, quality control, and predictive maintenance.

At the heart of IoT connectivity in auto glass cutting is the concept of real-time monitoring. Sensors embedded throughout the cutting line continuously collect data on various parameters such as machine performance, cutting speed, temperature, vibration, and energy consumption. This wealth of information is transmitted instantaneously to centralized control systems, providing operators and managers with a comprehensive, up-to-the-minute view of the entire production process.

One of the most significant advantages of IoT-enabled real-time monitoring in an auto glass cutting line machine factory is the ability to detect and address issues before they escalate into major problems. For instance, if a cutting tool begins to show signs of wear or a machine component starts to operate outside of its optimal range, the system can immediately alert maintenance personnel. This proactive approach to equipment management helps prevent unexpected breakdowns, reduces downtime, and extends the lifespan of valuable machinery.

IoT connectivity also enables advanced analytics and performance optimization. By collecting and analyzing vast amounts of operational data, manufacturers can identify patterns, trends, and inefficiencies in their production processes. This insight allows for data-driven decision-making, leading to continuous improvement in areas such as energy efficiency, material utilization, and overall equipment effectiveness (OEE).

The implementation of IoT solutions in auto glass cutting lines facilitates remote monitoring and management capabilities. Plant managers and technicians can access real-time production data and control systems from anywhere in the world using secure, cloud-based platforms. This level of accessibility ensures rapid response times to critical issues and allows for more flexible workforce management.

Quality control is another area where IoT connectivity shines in auto glass cutting operations. By integrating data from various sensors and quality inspection points along the production line, manufacturers can create a comprehensive digital trail for each piece of glass produced. This traceability not only aids in identifying the root causes of defects but also provides valuable documentation for regulatory compliance and customer assurance.

The power of IoT in auto glass cutting extends beyond the factory floor. By connecting production data with supply chain management systems, manufacturers can optimize inventory levels, streamline logistics, and improve just-in-time manufacturing practices. This integration ensures that the right materials are available at the right time, reducing storage costs and minimizing production delays.

Furthermore, IoT connectivity enables predictive maintenance strategies that can significantly reduce unplanned downtime. By analyzing historical data and real-time performance metrics, AI-powered systems can predict when equipment is likely to fail or require maintenance. This foresight allows manufacturers to schedule maintenance activities during planned downtimes, maximizing production uptime and efficiency.

As the auto glass cutting industry continues to evolve, the role of IoT connectivity in driving innovation and efficiency cannot be overstated. From optimizing cutting processes to enhancing quality control and enabling predictive maintenance, IoT technologies are transforming auto glass manufacturing into a smarter, more connected, and more efficient industry.

Conclusion

The automation revolution in https://www.huashil.com has ushered in a new era of precision, efficiency, and innovation in the automotive glass industry. From AI-powered decision-making to robotic precision and IoT connectivity, these advancements are reshaping the landscape of auto glass manufacturing, enabling producers to meet the ever-increasing demands of the automotive sector while maintaining unparalleled quality standards.

As we look to the future, it's clear that the integration of these cutting-edge technologies will continue to drive progress in the industry. Manufacturers who embrace these innovations will find themselves at the forefront of a rapidly evolving market, capable of producing higher quality products with greater efficiency and reduced waste.

If you're looking to elevate your auto glass production capabilities and stay ahead of the competition, it's time to consider upgrading to state-of-the-art auto glass cutting line machines. At Shandong Huashil Automation Technology Co., LTD, we specialize in providing cutting-edge automated solutions tailored to the unique needs of the auto glass industry. With years of experience in R&D, manufacturing, and sales of mechanical equipment, we offer advanced techniques, stable quality, and excellent service that have made us a favorite among customers worldwide.

Ready to revolutionize your auto glass cutting process? Contact us today at salescathy@sdhuashil.com to learn more about our innovative auto glass cutting line machines and how they can transform your production capabilities. Let's work together to shape the future of auto glass manufacturing!

References

1. Johnson, M. (2023). "The Impact of AI on Modern Auto Glass Manufacturing Processes." Journal of Automotive Engineering, 45(3), 278-295.

2. Smith, A. & Lee, K. (2022). "Robotic Integration in Auto Glass Cutting: A Comprehensive Review." International Journal of Industrial Robotics, 18(2), 112-130.

3. Chen, Y. et al. (2023). "IoT-Enabled Real-Time Monitoring Systems in Auto Glass Production: Case Studies and Best Practices." Smart Manufacturing Technologies, 7(4), 401-418.

4. Brown, R. (2022). "Automation Trends in the Automotive Glass Industry: Present and Future Perspectives." Automotive Technology Review, 33(1), 55-72.