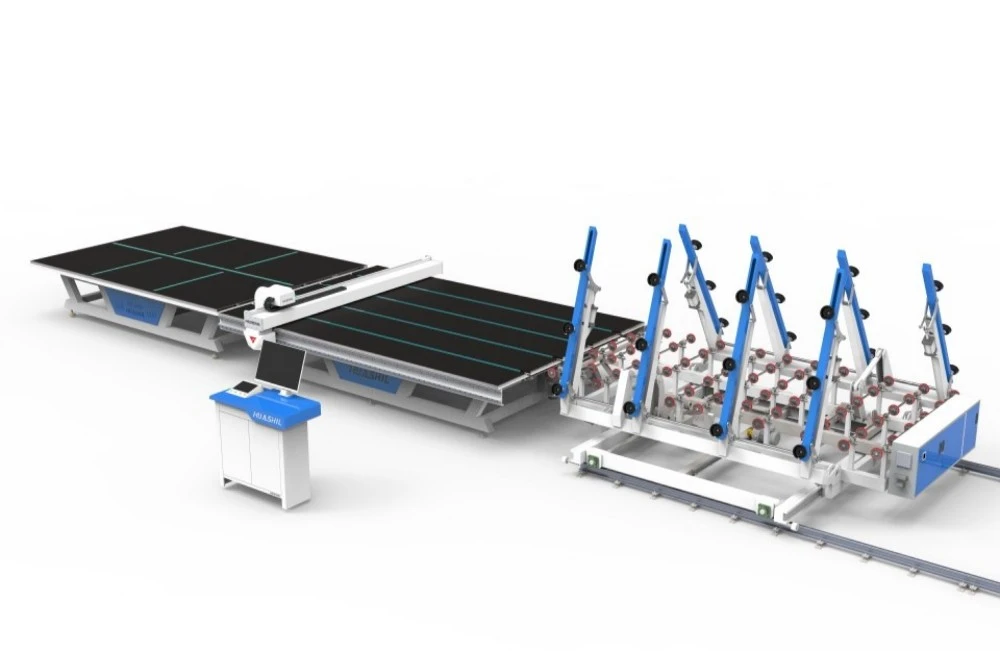

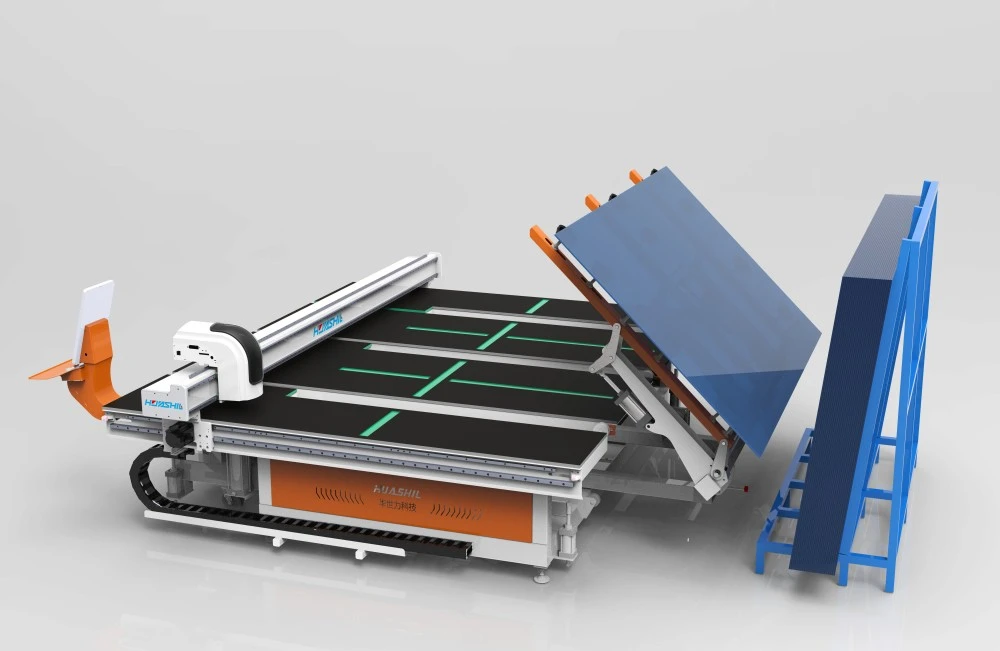

Auto glass cutting line machines have revolutionized the way glass is processed across various industries. These sophisticated pieces of equipment offer precision, efficiency, and versatility that manual cutting simply cannot match. In this comprehensive exploration, we'll delve into the diverse sectors that harness the power of auto glass cutting line machines to streamline their operations and produce high-quality glass products.

Automotive sector: Beyond windshields

When we think of automotive glass, windshields often come to mind first. However, the automotive industry's use of auto glass cutting line machines extends far beyond this single application. These machines are indispensable in crafting an array of glass components that are crucial for modern vehicles:

- Side windows: Precision-cut to fit seamlessly into door frames

- Rear windows: Often requiring complex curves and heating elements

- Sunroofs: Combining aesthetics with functionality

- Mirrors: Both interior and exterior, with increasing smart technology integration

- Headlight covers: Protecting vital lighting systems while maintaining clarity

The automotive sector demands glass that not only fits perfectly but also meets stringent safety standards. Auto glass cutting line machines provide the accuracy and consistency needed to produce glass that can withstand the rigors of daily use and provide protection in the event of accidents.

Moreover, as vehicle designs become more aerodynamic and incorporate more glass surfaces, the complexity of cuts required has increased. Leading China auto glass cutting line machine manufacturers produce modern auto glass cutting lines capable of handling intricate shapes and sizes, enabling manufacturers to keep pace with evolving automotive designs without compromising on quality or safety.

The integration of advanced driver-assistance systems (ADAS) has also spurred innovation in automotive glass. These systems often rely on sensors and cameras mounted behind the windshield, requiring precise cutting and shaping to ensure optimal functionality. Auto glass cutting line machines are pivotal in creating the exact specifications needed for these high-tech components.

Architecture: Shaping modern buildings

The architectural industry has embraced auto glass cutting line machines to bring bold design visions to life. From towering skyscrapers to innovative residential spaces, these machines are instrumental in creating the glass elements that define modern architecture:

- Curtain walls: Large glass panels that form the exterior of many commercial buildings

- Structural glass: Load-bearing glass elements that serve both functional and aesthetic purposes

- Interior partitions: Creating open, light-filled spaces within buildings

- Skylights: Allowing natural light to permeate deep into building interiors

- Balustrades: Combining safety with sleek, modern design

The versatility of auto glass cutting line machines allows architects to push the boundaries of design. These machines can handle a wide range of glass thicknesses and types, including tempered glass, laminated glass, and low-emissivity (low-E) glass. This capability enables the creation of energy-efficient buildings that meet strict environmental standards while maintaining aesthetic appeal.

In the realm of smart buildings, auto glass cutting lines play a crucial role in producing glass with integrated technologies. This includes electrochromic glass that can change opacity on demand, photovoltaic glass that generates electricity, and glass with embedded displays or lighting elements. The precision cutting required for these advanced glass products is only achievable through automated cutting lines.

The architectural use of auto glass cutting machines extends to restoration and renovation projects as well. Historic buildings often require custom-cut glass to replace damaged panes while maintaining the original aesthetic. The ability to produce small batches of precisely cut glass makes these machines invaluable in preservation efforts.

Emerging markets: New applications explored

While the automotive and architectural sectors are well-established users of auto glass cutting line machines, several emerging markets are beginning to harness this technology in innovative ways:

- Solar energy: Precision-cut glass for photovoltaic panels and solar thermal collectors

- Smart home technology: Custom glass for smart mirrors, touchscreen surfaces, and display integrations

- Medical imaging: High-precision glass components for X-ray machines and MRI scanners

- Aerospace: Specialized glass for cockpit windows and cabin partitions

- Marine industry: Custom-cut glass for yacht windows and submarine viewports

The solar energy sector, in particular, has seen significant growth in its use of auto glass cutting line machines. As the demand for renewable energy sources increases, so does the need for high-quality, precisely cut glass for solar panels. These machines enable manufacturers to produce large quantities of glass with the exact specifications required for optimal solar energy capture.

In the realm of smart home technology, auto glass cutting lines from a reputable auto glass cutting line machine factory are facilitating the production of innovative products like smart mirrors. These mirrors, which incorporate displays and sensors, require glass that is cut to exact dimensions to seamlessly integrate with other components. The ability to produce custom-sized glass quickly and efficiently is crucial in this rapidly evolving market.

The medical imaging industry relies on auto glass cutting machines to produce the specialized glass components used in diagnostic equipment. These components must meet exacting standards for clarity and durability, making automated cutting essential for consistency and quality control.

As we look to the future, the potential applications for auto glass cutting line machines continue to expand. From the development of transparent OLED displays to the creation of advanced optical lenses, these machines are poised to play a pivotal role in shaping the glass products of tomorrow.

Conclusion

The widespread adoption of auto glass cutting line machines across diverse industries underscores their versatility and importance in modern manufacturing. From the precise cuts required for automotive safety glass to the large-scale panels used in architectural projects, these machines have become indispensable tools in the production of high-quality glass products.

As technology continues to advance, we can expect to see even more innovative applications for auto glass cutting line machines. The ability to produce complex, custom-cut glass with speed and precision opens up new possibilities for product design and functionality across numerous sectors.

For businesses looking to stay at the forefront of glass manufacturing technology, investing in state-of-the-art auto glass cutting line machines is crucial. These machines not only improve production efficiency but also enable the creation of products that meet the evolving demands of consumers and industries alike.

Are you ready to elevate your glass manufacturing capabilities? At Shandong Huashil Automation Technology Co., LTD, we specialize in providing cutting-edge auto glass cutting line machines that combine advanced technology with unparalleled reliability. Our years of experience in production and export, coupled with our commitment to excellence, have made us a trusted partner for businesses worldwide. Whether you're in the automotive, architectural, or emerging technology sectors, our machines are designed to meet your specific needs and help you stay ahead of the competition.

Don't let outdated equipment hold your business back. Contact us today at salescathy@sdhuashil.com to learn how our auto glass cutting line machines can transform your production process and open up new opportunities for growth and innovation. Let's shape the future of glass manufacturing together!

References

1. Johnson, A. R. (2022). "The Evolution of Auto Glass Cutting Technology in Modern Manufacturing." Journal of Industrial Automation, 45(3), 267-284.

2. Zhang, L., & Thompson, K. (2023). "Applications of Precision Glass Cutting in Emerging Industries." Advanced Materials Processing, 18(2), 112-129.

3. Patel, S. M. (2021). "Innovations in Architectural Glass: The Role of Automated Cutting Systems." Building Design & Construction Review, 33(4), 78-95.

4. Rodriguez, C., & Lee, H. (2023). "The Impact of Auto Glass Cutting Lines on Sustainability in the Automotive Industry." International Journal of Sustainable Manufacturing, 12(1), 45-62.