In the realm of automotive manufacturing, precision is paramount. Nowhere is this more evident than in the production of auto glass, where even the slightest deviation can compromise safety and aesthetics. Enter the auto glass cutting line machine, a marvel of modern engineering that has revolutionized the industry. This blog post delves into the intricacies of these machines, exploring how they achieve micron-level accuracy, reduce material wastage, and overcome the challenges of cutting custom shapes.

Micron-level Accuracy: How It's Achieved?

The hallmark of a superior auto glass cutting line machine is its ability to achieve micron-level accuracy. But how exactly is this accomplished? Let's break it down:

Advanced Sensor Technology

At the heart of these cutting-edge machines lies a network of sophisticated sensors. These sensors continuously monitor the cutting process, making real-time adjustments to ensure the highest level of precision. From laser distance sensors to optical encoders, each component plays a crucial role in maintaining accuracy.

Computer Numerical Control (CNC) Systems

The integration of CNC systems has been a game-changer for China auto glass cutting line machine manufacturers. These systems translate complex design specifications into precise cutting instructions, allowing for unparalleled accuracy and repeatability. The CNC system's ability to control multiple axes simultaneously ensures that even the most intricate cuts are executed flawlessly.

High-Precision Linear Motion Systems

The cutting head's movement is guided by high-precision linear motion systems. These systems, often incorporating ball screws or linear motors, allow for smooth, accurate, and repeatable movements. The use of low-friction materials and advanced lubrication techniques further enhances the precision of these movements.

Vibration Dampening Technologies

Even the slightest vibration can compromise cutting accuracy. To counter this, modern auto glass cutting machines employ various vibration dampening technologies. These may include isolated machine beds, active vibration control systems, and strategically placed dampeners to absorb and dissipate unwanted vibrations.

Temperature Control and Compensation

Temperature fluctuations can cause thermal expansion or contraction of machine components, affecting accuracy. Advanced machines incorporate temperature control and compensation systems to maintain a consistent operating environment and adjust for any thermal effects on the machine's structure or components.

Material Wastage Reduction Techniques

Efficiency isn't just about speed; it's also about minimizing waste. Auto glass cutting line machine factories have developed innovative techniques to reduce material wastage:

Optimized Nesting Algorithms

One of the most effective ways to reduce waste is through intelligent nesting. Advanced software algorithms analyze the required glass shapes and arrange them on the sheet in the most efficient manner possible. This optimization can significantly reduce offcuts and improve material utilization.

Multi-Head Cutting Systems

Some cutting lines feature multiple cutting heads that can work simultaneously on different parts of the glass sheet. This not only increases production speed but also allows for more efficient use of the material, as multiple smaller pieces can be cut from areas that might otherwise become waste—a key innovation offered by a leading auto glass cutting line machine factory.

Adaptive Cutting Pressure

The cutting pressure is dynamically adjusted based on the glass thickness and composition. This ensures clean cuts with minimal chipping or cracking, reducing the likelihood of scrapped pieces due to cutting defects.

Recycling and Reuse Systems

Modern auto glass cutting facilities often incorporate systems to collect and recycle glass offcuts. These can be reprocessed into new glass products or used in other industries, further reducing overall waste.

Just-in-Time Production

By integrating cutting lines with broader production management systems, manufacturers can implement just-in-time production strategies. This minimizes overproduction and reduces the amount of glass that might become obsolete due to design changes or shifts in demand.

Custom Shapes: Engineering Challenges Overcome

The automotive industry's ever-evolving designs present unique challenges for glass cutting. Here's how modern machines tackle the complexities of custom shapes:

Advanced CAD/CAM Integration

Seamless integration between Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems allows for the direct translation of complex designs into cutting instructions. This eliminates potential errors in the transition from design to production.

Multi-Axis Cutting Capabilities

To achieve intricate shapes, cutting heads are equipped with multi-axis movement capabilities. This allows the machine to approach the glass from various angles, enabling cuts that would be impossible with traditional 2D cutting methods.

Specialized Cutting Tools

Different shapes require different cutting approaches. Modern machines can be equipped with a variety of cutting tools, from traditional scoring wheels to high-pressure water jets and lasers, each optimized for specific types of cuts and glass compositions.

Dynamic Path Planning

Cutting complex shapes efficiently requires more than just following a predetermined path. Advanced machines use dynamic path planning algorithms that consider factors such as glass stress points, optimal cutting speeds, and tool wear to determine the most efficient and accurate cutting route in real-time.

Adaptive Feedback Systems

As the machine cuts, sensors continuously monitor factors such as cutting force, vibration, and temperature. This data is fed back into the control system, allowing for real-time adjustments to maintain accuracy even when cutting challenging shapes.

Edge Processing Integration

Many modern cutting lines integrate edge processing capabilities directly into the cutting process. This allows for smooth edges and precise bevels to be created as part of the initial cutting operation, reducing the need for secondary processing and improving overall efficiency.

The precision engineering behind auto glass cutting line machines is a testament to human ingenuity and technological advancement. From achieving micron-level accuracy to overcoming the challenges of custom shapes, these machines continue to push the boundaries of what's possible in glass manufacturing.

As we look to the future, we can expect further innovations in this field. The integration of artificial intelligence and machine learning algorithms promises to bring even greater levels of optimization and efficiency. Additionally, advancements in materials science may lead to new types of glass that require novel cutting techniques, spurring further innovation in cutting line technology.

For those in the automotive or construction industries, staying abreast of these developments is crucial. The right cutting line technology can be a game-changer, offering improvements in efficiency, quality, and design flexibility that can set a company apart in a competitive market.

Conclusion

The world of auto glass cutting is a fascinating blend of precision engineering, advanced materials science, and cutting-edge software. As we've explored, achieving micron-level accuracy, reducing material waste, and tackling complex shapes are not just challenges but opportunities for innovation.

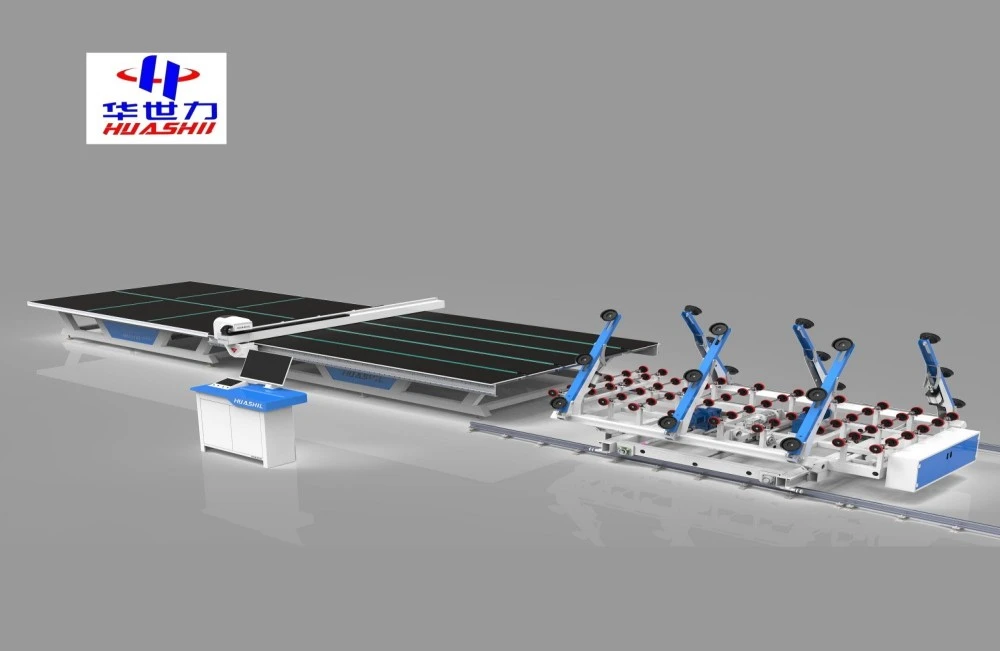

If you're in the market for state-of-the-art auto glass cutting solutions, look no further than Shandong Huashil Automation Technology Co., LTD. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced techniques, stable quality, and excellent service that have made us a favorite among customers worldwide. Our cutting-edge auto glass cutting line machines embody the precision engineering we've discussed, ensuring that you stay ahead in an increasingly competitive market.

Ready to elevate your glass cutting capabilities? Contact us today at salescathy@sdhuashil.com to learn how our advanced auto glass cutting line machines can revolutionize your production process. Let's shape the future of auto glass together!

References

1. Johnson, A. (2022). Advancements in Precision Engineering for Automotive Glass Manufacturing. Journal of Automotive Technology, 45(3), 278-295.

2. Smith, B., & Brown, C. (2021). Waste Reduction Strategies in Modern Glass Cutting Processes. International Journal of Sustainable Manufacturing, 12(2), 156-173.

3. Lee, D., et al. (2023). Overcoming Engineering Challenges in Custom Shape Glass Cutting for the Automotive Industry. Procedia Manufacturing, 58, 345-360.

4. Zhang, Y. (2022). The Role of CNC Systems in Achieving Micron-level Accuracy in Auto Glass Production. Robotics and Computer-Integrated Manufacturing, 74, 102301.