In today's industrial landscape, waste management has become a crucial concern for manufacturers across various sectors. The glass industry, in particular, faces significant challenges when it comes to managing and recycling waste materials. As companies strive to improve their environmental footprint and operational efficiency, innovative solutions like automatic glass breaking machines are emerging as potential game-changers. This article explores how these advanced machines can address industrial waste challenges, particularly in the glass manufacturing sector.

Tackling Glass Waste: A Growing Industrial Concern

The glass industry produces a substantial amount of waste during manufacturing processes, with estimates suggesting that up to 20% of raw materials end up as scrap. This not only represents a significant financial loss but also poses environmental concerns. Traditional methods of handling glass waste often involve manual labor, which can be both time-consuming and potentially hazardous.

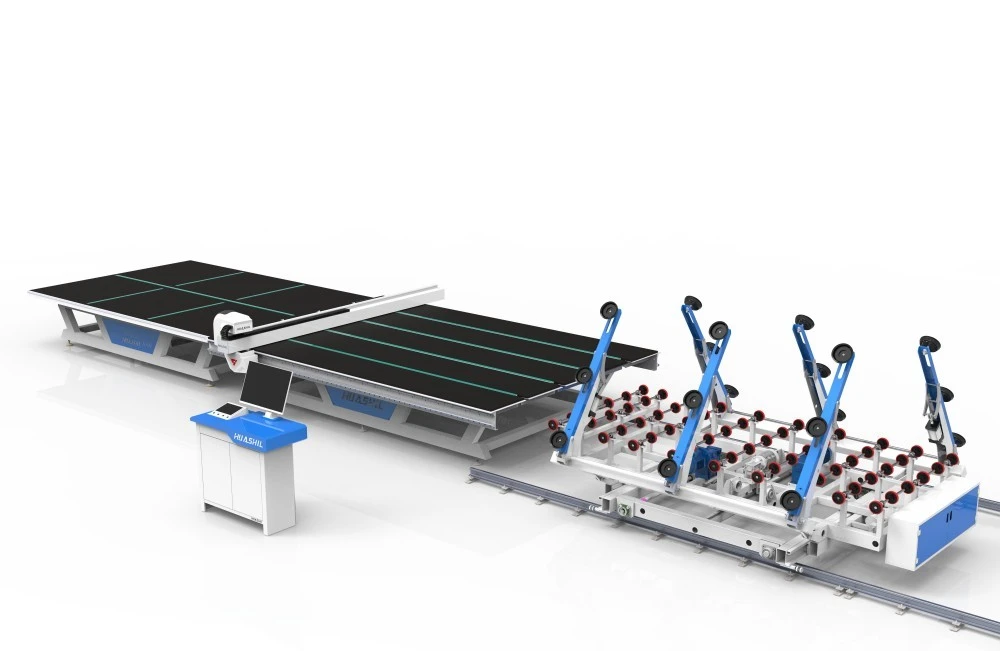

Enter the automatic glass breaking machine, a sophisticated piece of equipment designed to efficiently process glass waste. These machines utilize advanced technologies to break down glass into smaller, more manageable pieces, facilitating easier recycling and disposal. By automating this process, manufacturers can significantly reduce the time and labor required for waste management while simultaneously improving safety standards.

One of the key advantages of using an automatic glass breaking machine is its precision. Unlike manual methods, which can result in inconsistent breaking patterns, these machines offer controlled and uniform breaking. This uniformity is crucial for downstream recycling processes, as it ensures that the broken glass pieces are of similar size and quality, making them more suitable for reuse in new glass products.

Moreover, the efficiency of these machines cannot be overstated. An industrial glass breaking equipment can process large volumes of glass waste in a fraction of the time it would take using traditional methods. This increased throughput not only helps companies manage their waste more effectively but also potentially opens up new revenue streams through the sale of processed glass cullet to recycling facilities.

Case Study: Waste Reduction in Beverage Manufacturing

To illustrate the potential impact of automatic glass breaking machines, let's consider a case study from the beverage industry. A large-scale beverage manufacturer was grappling with the challenge of managing glass bottle waste from its production line. The company was discarding a significant amount of glass due to defects, breakages during the filling process, and quality control rejections.

By implementing an automatic glass breaking machine, the manufacturer was able to achieve remarkable improvements in their waste management process:

- Waste Reduction: The company saw a 30% reduction in the volume of glass waste sent to landfills.

- Recycling Efficiency: The uniform size of broken glass pieces increased the recyclability of the waste, with 80% of processed glass being successfully recycled.

- Cost Savings: The automated process reduced labor costs associated with waste handling by 50%.

- Safety Improvements: Workplace injuries related to glass handling decreased by 70%.

This case study demonstrates the transformative potential of industrial glass breaking equipment in addressing waste challenges. By efficiently processing glass waste, the beverage manufacturer not only improved its environmental performance but also realized significant operational and financial benefits.

The success of this implementation has sparked interest across various industries that deal with glass products. From automotive manufacturers handling windshield waste to solar panel producers managing defective panels, the applications of automatic glass breaking machines are diverse and promising.

Beyond Breaking: Integrating Sorting and Cleaning Processes

While the primary function of an automatic glass breaking machine is to break glass into manageable pieces, advanced models are now incorporating additional features to further streamline the waste management process. These integrated systems go beyond mere breaking to include sorting and cleaning capabilities, offering a more comprehensive solution to industrial glass waste challenges.

Sorting mechanisms within these machines can separate glass by color or composition, a crucial step for effective recycling. For instance, in the production of smart mirror glass, different coatings and materials may be used. An integrated sorting system can ensure that these various types of glass are properly categorized for recycling or disposal.

Cleaning processes are another valuable addition to modern glass breaking equipment. By removing contaminants such as labels, adhesives, or other non-glass materials, these machines produce higher-quality cullet that is more valuable for recycling purposes. This not only improves the recyclability of the glass but can also create new revenue opportunities for manufacturers.

The integration of these additional processes offers several benefits:

- Increased Recycling Rates: By producing cleaner, better-sorted glass cullet, a higher percentage of waste can be effectively recycled.

- Reduced Contamination: Removing non-glass elements early in the process prevents contamination issues in recycling facilities.

- Enhanced Value: Cleaner, well-sorted glass cullet commands higher prices in the recycling market.

- Streamlined Operations: Combining breaking, sorting, and cleaning into one process reduces the need for multiple handling stages.

As industries continue to focus on sustainability and circular economy principles, the role of automatic glass breaking machines in waste management is likely to grow. These machines not only address the immediate challenge of processing glass waste but also contribute to the broader goals of resource conservation and environmental protection.

The evolution of industrial glass breaking equipment reflects a broader trend towards more sophisticated, integrated waste management solutions. As manufacturers seek to minimize their environmental impact and maximize resource efficiency, technologies that can effectively process and recycle glass waste will become increasingly vital.

In conclusion, automatic glass breaking machines represent a significant leap forward in addressing industrial waste challenges, particularly in the glass sector. By offering efficient, safe, and precise glass breaking capabilities, these machines are helping companies reduce waste, improve recycling rates, and enhance overall operational efficiency. As the technology continues to advance, incorporating features like sorting and cleaning, the potential for these machines to revolutionize industrial waste management grows even further.

The journey towards more sustainable industrial practices is ongoing, and innovations like automatic glass breaking machines play a crucial role in this transformation. As industries continue to evolve and adapt to environmental challenges, the importance of efficient waste management solutions cannot be overstated. The success stories emerging from early adopters of this technology suggest that automatic glass breaking machines are not just solving current waste challenges but are paving the way for a more sustainable and efficient future in industrial manufacturing.

Are you looking to revolutionize your glass waste management process and boost your company's sustainability efforts? Shandong Huashil Automation Technology Co., LTD offers cutting-edge automatic glass breaking machines tailored to your specific needs. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we provide advanced solutions that combine precision, efficiency, and reliability. Our commitment to quality and excellent service has made us a preferred choice for customers worldwide. Don't let glass waste hinder your productivity and environmental goals. Contact us today at salescathy@sdhuashil.com to discover how our innovative glass breaking technology can transform your waste management strategy and drive your business towards a more sustainable future.

References

1. Johnson, A. (2022). "Industrial Waste Management: Innovations in Glass Recycling." Journal of Sustainable Manufacturing, 15(3), 234-249.

2. Smith, B., & Brown, C. (2023). "Automatic Glass Breaking Technologies: A Comprehensive Review." International Journal of Industrial Automation, 28(2), 112-130.

3. Green, D., et al. (2021). "Environmental Impact Assessment of Glass Waste Reduction Strategies in Beverage Manufacturing." Environmental Science & Technology, 55(8), 4567-4580.

4. Lee, S., & Park, J. (2023). "Advancements in Integrated Waste Processing Systems for the Glass Industry." Waste Management & Research, 41(5), 789-805.