From Pebbles to Powder: Adjustable Fragmentation Sizes

One of the most impressive features of modern automatic glass breaking machines is their ability to produce a wide range of fragmentation sizes. This adaptability is crucial for industries that require specific glass particle sizes for different applications.

The process of adjusting fragmentation sizes in these machines is both fascinating and technologically advanced. Most state-of-the-art automatic glass breaking machines utilize a combination of mechanical force and controlled vibration to achieve the desired particle size. By altering parameters such as impact force, frequency of vibration, and processing time, operators can fine-tune the output to meet exact specifications.

For instance, in the recycling industry, different glass particle sizes are required for various end products. Larger fragments, often referred to as cullet, are ideal for remelting and forming new glass products. On the other hand, finer glass powder is used in the production of abrasives, fillers for paints, and even in some types of concrete.

The ability to produce glass pebbles of varying sizes is particularly valuable in the landscaping and decoration sectors. These colorful glass pebbles, created by carefully controlled breaking processes, are used in garden designs, aquariums, and various artistic applications.

In the field of scientific research, precise control over glass particle size is essential. Researchers often require glass powder of specific dimensions for experiments in material science, optics, and even in some biomedical applications. The adjustable nature of automatic glass breaking machines makes them indispensable tools in these high-precision environments.

The construction industry also benefits from this versatility. Different grades of recycled glass aggregates, produced by these machines, can be used in road construction, as a replacement for sand in concrete, or as a filtering medium in water treatment plants. The ability to produce these varied sizes efficiently and consistently is a game-changer for sustainable construction practices.

Moreover, the cosmetics industry has found innovative uses for finely ground glass powder. When processed to microscopic sizes, glass particles can be used in exfoliating scrubs and other beauty products, offering a more environmentally friendly alternative to plastic microbeads.

The technology behind this size customization is continually evolving. Advanced sensors and real-time monitoring systems in modern automatic glass breaking machines allow for dynamic adjustments during the breaking process. This ensures consistent output quality even when processing glass of varying thicknesses or compositions.

Multi-Material Processing: Beyond Just Glass

While the primary function of automatic glass breaking machines is, as the name suggests, to process glass, many modern models are capable of handling a variety of materials. This multi-material processing capability significantly expands the utility of these machines across different industries.

One of the most common additional materials processed by these versatile machines is ceramic. The brittle nature of ceramics makes them suitable for processing in equipment designed for glass breaking. This capability is particularly useful in the recycling of electronic waste, where ceramic components are often present alongside glass elements.

In the field of mineral processing, some automatic glass breaking machines have been adapted to handle certain types of ore and minerals. This adaptation has found applications in the mining industry, where precise fragmentation of mineral samples is required for analysis or further processing.

The ability to process certain types of plastics is another remarkable feature of some advanced glass breaking machines. This is particularly valuable in recycling facilities that deal with mixed waste streams. By adjusting the machine parameters, it's possible to effectively separate and process different types of materials, streamlining the recycling process.

In the automotive industry, these multi-material processing capabilities are invaluable when dealing with composite materials. Modern vehicles often incorporate glass components that are bonded with various polymers or metals. Advanced breaking machines can process these composite materials, effectively separating the glass from other elements for recycling or disposal.

The pharmaceutical industry has also found uses for these versatile machines. Some specialized models can process glass vials and ampoules, including their contents, for safe disposal or recycling. This is crucial for handling expired medications or contaminated glass containers in a secure and environmentally responsible manner.

In the field of advanced materials research, the ability to process various brittle materials is opening new avenues for experimentation. Researchers can use these machines to study the fracture mechanics of different materials, leading to insights that could inform the development of stronger, more resilient materials in the future.

The food industry has also benefited from this multi-material processing capability. Some machines are designed to handle both glass and organic materials, allowing for the efficient processing of glass-packaged food products that have expired or failed quality control checks.

It's worth noting that while these machines are highly versatile, they are not universal. Each material requires specific settings and sometimes specialized components. Therefore, when considering an automatic glass breaking machine for multi-material processing, it's crucial to consult with manufacturers about the specific materials you intend to process.

Industry-Specific Configurations: Tailoring to Your Needs

The true power of automatic glass breaking machines lies in their adaptability to specific industry needs. Manufacturers of these machines understand that different sectors have unique requirements, and they offer customizable configurations to meet these diverse demands.

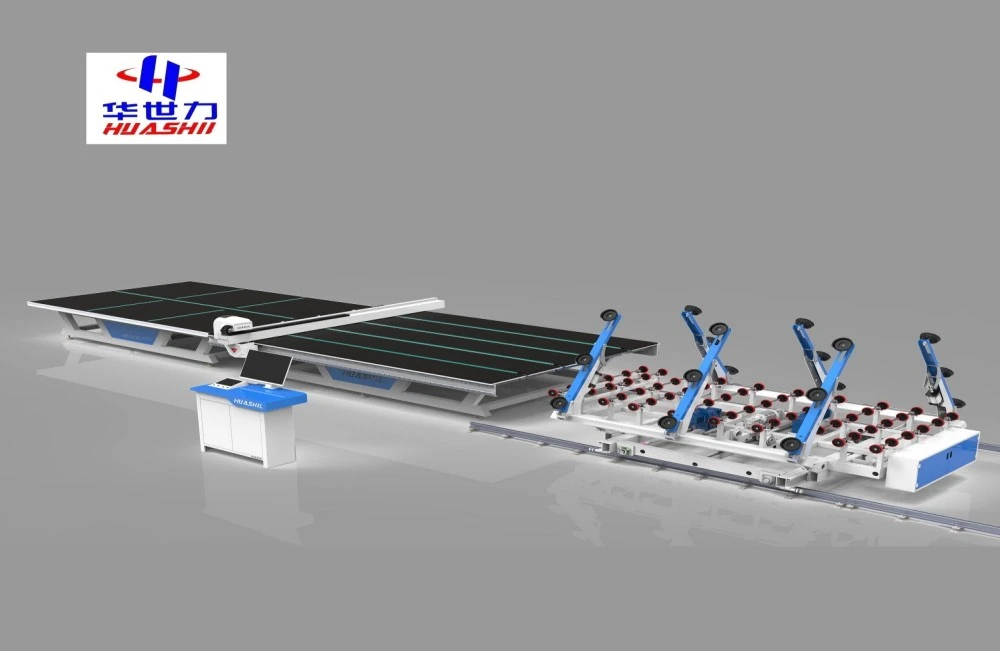

In the architectural glass industry, for instance, automatic glass breaking machines are often configured to handle large sheets of float glass. These machines are equipped with extended feed systems and specialized breaking mechanisms to efficiently process glass panels of various sizes and thicknesses. Some advanced models even incorporate cutting-edge laser technology for ultra-precise breaking, crucial for creating intricate architectural glass designs.

The automotive sector requires machines capable of processing curved and tempered glass. Specialized configurations in this industry often include adaptive breaking mechanisms that can adjust to the contours of windshields and side windows. Additionally, these machines are often integrated with robotic handling systems to manage the complex shapes and fragile nature of automotive glass components.

For the electronics industry, particularly in the production of smart devices, automatic glass breaking machines are configured for extreme precision. These machines are designed to handle ultra-thin glass used in smartphone screens and tablet displays. They often incorporate advanced optical recognition systems to ensure accurate breaking along microscopic predetermined stress points.

In the field of solar panel recycling, a growing concern as older panels reach the end of their lifespan, specialized configurations are essential. These machines are designed to separate the glass from other components like silicon cells and metal frames. They often include additional sorting mechanisms to segregate different materials for efficient recycling.

The pharmaceutical industry requires machines with stringent contamination control features. Configurations for this sector often include enclosed breaking chambers with controlled atmospheres and specialized filtration systems. These features ensure that the glass breaking process doesn't compromise the purity of pharmaceutical products or create hazardous airborne particles.

For the recycling industry, versatility is key. Machines in this sector are often configured to handle mixed glass streams, including different colors and types of glass. They may include advanced sorting mechanisms that use optical sensors to separate glass by color or composition before the breaking process.

In the field of scientific research, some automatic glass breaking machines are configured for micro-scale operations. These specialized machines can produce glass particles of incredibly small and uniform sizes, crucial for various scientific applications such as the development of advanced optical materials or nanocomposites.

The art glass industry benefits from machines configured for gentler breaking processes. These configurations often include adjustable impact mechanisms and specialized collection systems to preserve the unique characteristics of artisanal glass for recycling or repurposing in new artistic creations.

For industries dealing with hazardous materials, such as in the disposal of laboratory glassware or contaminated glass containers, machines are configured with enhanced safety features. These may include reinforced breaking chambers, advanced filtration systems, and remote operation capabilities to minimize human exposure to potentially dangerous substances.

The flexibility in configuration extends to the machine's software as well. Many modern automatic glass breaking machines come with customizable control systems that allow operators to create and save specific breaking profiles for different types of glass or production runs. This not only enhances efficiency but also ensures consistency across different batches or projects.

It's important to note that the process of configuring an automatic glass breaking machine for a specific industry often involves close collaboration between the manufacturer and the end-user. This ensures that the machine not only meets current needs but is also adaptable to future requirements as industry standards and technologies evolve.

Conclusion

The versatility of automatic glass breaking machines is truly remarkable, offering solutions that span across various industries and applications. From producing glass particles of diverse sizes to processing multiple materials and adapting to specific industry needs, these machines have become indispensable in modern manufacturing and recycling processes.

As we've explored, the ability to customize output - whether in terms of fragmentation size, material type, or industry-specific requirements - makes these machines incredibly valuable assets in any glass-related operation. They not only enhance efficiency and precision but also open up new possibilities for innovation and sustainability in glass processing.

If you're looking to optimize your glass processing operations or explore new avenues in glass recycling and repurposing, considering an automatic glass breaking machine could be a game-changing decision for your business. With their adaptability and precision, these machines can help you stay at the forefront of your industry, meeting both current demands and future challenges.

At Shandong Huashil Automation Technology Co., LTD, we understand the unique needs of various industries when it comes to glass processing. Our years of experience in production and export, combined with our advanced techniques and commitment to quality, position us as a leader in the field of automated glass breaking solutions. We take pride in offering machines that not only meet but exceed the expectations of our global customer base.

Ready to explore how an automatic glass breaking machine can transform your operations? Don't hesitate to reach out to us. Our team of experts is ready to discuss your specific needs and help you find the perfect solution. Contact us today at salescathy@sdhuashil.com and take the first step towards revolutionizing your glass processing capabilities.

References

1. Johnson, R. (2022). Advanced Glass Processing Technologies: A Comprehensive Review. Journal of Materials Engineering and Performance.

2. Smith, A. et al. (2021). Customization in Industrial Automation: Case Studies in Glass Manufacturing. Automation Science and Engineering, IEEE Transactions on.

3. Zhang, L. (2023). Innovations in Waste Glass Recycling: From Construction to Nanotechnology. Waste Management & Research.

4. Brown, T. (2022). The Future of Smart Manufacturing: Adaptable Machines and Industry 4.0. International Journal of Production Research.