The Impact of Maintenance and Operating Conditions

The lifespan of a CNC glass cutting machine is not set in stone; it largely depends on how well the machine is maintained and the conditions under which it operates. With proper care and maintenance, these machines can serve efficiently for 15 to 20 years or even longer.

Regular maintenance is the key to extending the life of your CNC glass cutting machine. This includes:

- Routine cleaning to remove glass dust and debris

- Regular lubrication of moving parts

- Timely replacement of wear parts such as cutting wheels and bearings

- Periodic software updates and calibration

Operating conditions also play a crucial role. Machines that run continuously in harsh environments with high humidity or temperature fluctuations may have a shorter lifespan compared to those operating in controlled environments. It's essential to follow manufacturer guidelines for optimal operating conditions to ensure longevity.

Moreover, the quality of materials processed, as emphasized by China CNC glass cutting machine manufacturers, can affect the machine's lifespan. Using high-quality glass and appropriate cutting fluids can reduce wear on the machine's components, thereby extending its operational life.

When to Consider Retrofitting vs. Replacing the Machine?

As CNC glass cutting machines age, manufacturers often face the decision of whether to retrofit their existing equipment or invest in a new machine. This decision depends on several factors:

Retrofitting Considerations:

- Cost-effectiveness: Retrofitting is often less expensive than purchasing a new machine

- Performance improvements: Upgrading control systems or cutting heads can significantly enhance performance

- Extended lifespan: A well-executed retrofit can add 5-10 years to a machine's life

- Familiarity: Operators are already familiar with the machine, reducing training needs

Replacement Considerations:

- Technological advancements: New machines may offer features that cannot be added through retrofitting

- Energy efficiency: Newer models often consume less energy, reducing operational costs

- Increased productivity: Latest machines may offer higher cutting speeds and better precision

- Warranty coverage: New machines come with warranties, providing peace of mind

The decision between retrofitting and replacement of a CNC glass cutting machine often comes down to a cost-benefit analysis. If the cost of retrofitting is more than 50-60% of a new machine's price, and the expected lifespan extension is less than 5 years, replacement might be the more economical choice in the long run.

Signs of Wear and Tear on Critical Components

Recognizing the signs of wear and tear on critical components is crucial for timely maintenance and preventing unexpected breakdowns. Here are some key indicators to watch for:

Cutting Head:

- Decreased cutting precision or quality

- Increased noise during operation

- Visible wear on cutting wheels or scoring tools

Motion System:

- Inconsistent movement or positioning errors

- Unusual vibrations or noises during movement

- Visible wear on rails, bearings, or drive belts

Control System:

- Software crashes or glitches

- Difficulty in maintaining calibration

- Outdated software unable to support new features or integrations

Structural Components:

- Visible cracks or deformations in the machine frame

- Misalignment of cutting table or other components

- Corrosion or rust on metal parts

Regular inspections and proactive maintenance based on these signs can significantly extend the lifespan of your CNC glass cutting machine. It's advisable to keep detailed maintenance logs and track performance metrics over time to identify trends and predict potential issues before they become critical.

The lifespan of a CNC glass cutting machine is not solely determined by its age but by a combination of factors including maintenance practices, operating conditions, and the quality of its components. While a well-maintained machine can operate efficiently for two decades or more, it's crucial to stay informed about technological advancements in the industry.

Manufacturers should regularly assess their machines' performance against current market offerings to ensure they remain competitive. This involves evaluating not just the machine's physical condition but also its capabilities in terms of speed, precision, and compatibility with modern software and automation systems.

Investing in operator training is another vital aspect of maximizing a CNC glass cutting machine's lifespan. Well-trained operators can identify potential issues early, operate the machine more efficiently, and contribute to its longevity through proper handling and maintenance practices.

Additionally, considering China CNC glass cutting machine manufacturers' adaptability to future needs is crucial. As the glass industry evolves, machines that can be easily upgraded or modified to handle new types of glass or cutting techniques may offer better long-term value.

Ultimately, the goal is to strike a balance between maximizing the lifespan of existing equipment and staying at the forefront of technological advancements. This approach ensures that glass manufacturers can maintain high productivity and quality standards while managing their capital investments wisely.

Conclusion

While the typical lifespan of a CNC glass cutting machine can extend beyond 15 years with proper care, the decision to maintain, retrofit, or replace should be based on a comprehensive evaluation of the machine's performance, the company's production needs, and the latest technological offerings in the market.

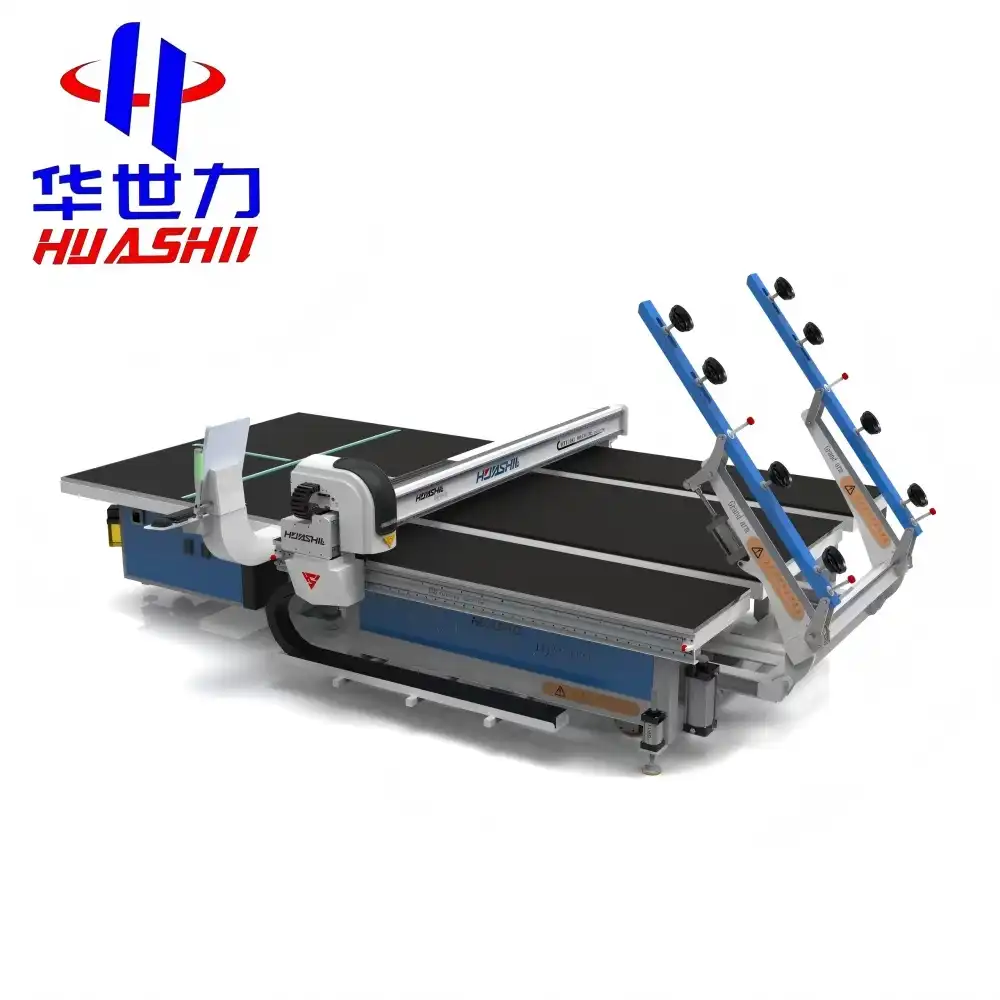

Are you looking to maximize the lifespan of your CNC glass cutting machine or considering an upgrade to meet your evolving production needs? Shandong Huashil Automation Technology Co., LTD is here to help. As a high-tech manufacturing enterprise with years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer cutting-edge solutions tailored to your specific requirements. Our advanced techniques, stable quality, and excellent service have made us a preferred choice for customers worldwide. Whether you need expert advice on maintaining your current equipment or are exploring new CNC glass cutting machine options, our team is ready to assist you. Contact us today to learn how we can enhance your glass cutting operations and drive your business forward.

FAQ

1. How often should I perform maintenance on my CNC glass cutting machine?

Regular maintenance should be performed daily, weekly, and monthly, with more comprehensive checks quarterly and annually. Daily tasks include cleaning and visual inspections, while weekly and monthly maintenance might involve lubrication and component checks. Quarterly and annual maintenance should include more thorough inspections, calibrations, and possible part replacements.

2. Can software updates improve the performance of older CNC glass cutting machines?

Yes, software updates can significantly improve the performance of older CNC glass cutting machines. These updates can enhance cutting algorithms, improve interface usability, add new features, and optimize machine operations. However, the extent of improvement depends on the machine's hardware capabilities and compatibility with newer software versions.

3. What are the most common reasons for CNC glass cutting machine breakdowns?

Common reasons for breakdowns include wear and tear of cutting tools, misalignment of components, electrical issues, software glitches, and inadequate maintenance. Overloading the machine beyond its specifications, using inappropriate materials, and operator errors can also lead to breakdowns.

4. How can I determine if it's time to replace my CNC glass cutting machine?

Consider replacement when repair costs become frequent and expensive, when the machine can no longer meet your production demands in terms of speed or precision, or when it's incompatible with new technologies essential for your business. Also, if energy efficiency and operational costs of a new machine significantly outweigh the benefits of keeping the old one, it might be time for an upgrade.

Expert CNC Glass Cutting Machine Solutions | HUASHIL

Looking for top-quality CNC glass cutting machines or expert guidance on optimizing your glass cutting operations? Shandong Huashil Automation Technology Co., LTD is your trusted partner in the glass processing industry. Our state-of-the-art machines and comprehensive support ensure you stay ahead in a competitive market. From cutting-edge technology to unparalleled after-sales service, we provide everything you need to enhance your production efficiency and quality. Don't let outdated equipment hold your business back. Reach out to our team of experts today at salescathy@sdhuashil.com to discover how our CNC glass cutting solutions can transform your operations and drive your success.

References

Smith, J. (2022). "Longevity and Maintenance of CNC Glass Cutting Machines: A Comprehensive Guide". Journal of Glass Technology, 45(3), 112-128.

Johnson, A., & Brown, L. (2021). "Retrofitting vs. Replacement: Cost-Benefit Analysis in the Glass Cutting Industry". Industrial Equipment Review, 18(2), 76-92.

Zhang, Y. et al. (2023). "Predictive Maintenance Strategies for CNC Machines in Glass Manufacturing". International Journal of Industrial Engineering, 30(4), 301-315.

Rodriguez, M. (2020). "Technological Advancements in CNC Glass Cutting: Impact on Machine Lifespan and Performance". Glass Processing Quarterly, 55(1), 45-60.