In the ever-evolving world of glass manufacturing, the CNC shaped glass cutting machine has emerged as a game-changer. With the introduction of advanced 5-axis technology, these machines have revolutionized the way we approach glass cutting, offering unprecedented precision, flexibility, and efficiency. This article delves into the intricacies of this cutting-edge technology, exploring its capabilities, applications, and the transformative impact it's having on the glass industry.

Exploring the Fifth Axis: Enhanced Capabilities

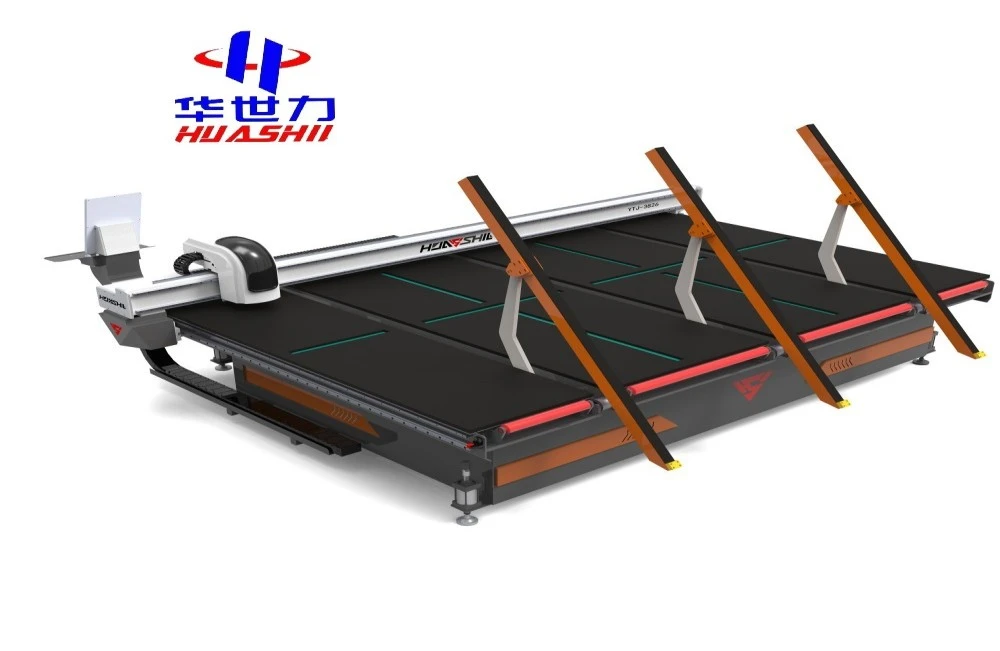

Traditional CNC glass cutting machines typically operate on three axes - X, Y, and Z. These allow for movement along the length, width, and depth of the glass sheet. However, the introduction of the fourth and fifth axes has opened up a whole new realm of possibilities.

The fourth axis, often referred to as the A-axis, allows for rotational movement around the X-axis. This enables the cutting tool to approach the glass from various angles, significantly expanding the range of cuts that can be made. But it's the addition of the fifth axis, or B-axis, that truly sets these machines apart.

The B-axis introduces rotation around the Y-axis, allowing for complex, multi-dimensional cuts that were previously impossible or extremely difficult to achieve. This means that a CNC shaped glass cutting machine equipped with 5-axis technology can create intricate, three-dimensional shapes and patterns with unprecedented ease and precision.

Some key advantages of 5-axis technology include:

- Increased flexibility in cutting angles and orientations

- Ability to create complex, multi-faceted shapes

- Reduced need for multiple setups, improving efficiency

- Enhanced surface finish quality

- Improved accuracy and repeatability

These capabilities have significantly expanded the potential applications of CNC glass cutting, from architectural elements to automotive components and beyond.

Complex Geometries: What 5-Axis Enables

The true power of 5-axis technology in CNC shaped glass cutting machines lies in its ability to create complex geometries that were previously unattainable or prohibitively expensive to produce. Let's explore some of the intricate shapes and designs that this technology enables:

- Compound Curves: 5-axis machines can effortlessly create compound curves - shapes that curve in multiple directions simultaneously. This is particularly useful in creating aerodynamic glass components for the automotive and aerospace industries.

- Undercuts: Traditional 3-axis machines struggle with undercuts - areas that are not visible from directly above the workpiece. 5-axis technology allows the cutting tool to approach these areas from the necessary angle, making undercuts possible.

- Spiral Forms: Creating spiral or helical shapes in glass is now achievable with 5-axis technology. This opens up new possibilities for artistic glass installations and unique architectural features.

- Variable Thickness Profiles: 5-axis machines can create glass pieces with varying thicknesses across their surface, allowing for more complex and functional designs.

- Textured Surfaces: By manipulating the cutting tool's angle and path, 5-axis machines can create textured surfaces on glass, adding both visual interest and functional properties like improved grip or light diffusion.

These capabilities have revolutionized glass design and manufacturing across various industries. Architects can now incorporate more daring and complex glass elements into their buildings. Product designers have greater freedom to create unique, eye-catching glass components with a CNC shaped glass cutting machine. Even artists are exploring the potential of 5-axis glass cutting to create intricate sculptures and installations.

Implementing 5-Axis: Challenges and Solutions

While the benefits of 5-axis technology in CNC shaped glass cutting machines are clear, implementing this advanced system comes with its own set of challenges. However, with the right approach and solutions, these hurdles can be overcome, allowing businesses to fully leverage the power of this technology.

Challenge 1: Increased Complexity

The addition of two extra axes significantly increases the complexity of machine operation and programming. Traditional G-code programming methods may struggle to handle the intricacies of 5-axis movements.

Solution: Advanced CAM (Computer-Aided Manufacturing) software specifically designed for 5-axis machining can greatly simplify the programming process. These software solutions can automatically generate optimal tool paths, taking into account all five axes to ensure efficient and collision-free operation.

Challenge 2: Higher Initial Costs

5-axis CNC shaped glass cutting machines typically come with a higher price tag compared to their 3-axis counterparts. This can be a significant barrier for smaller businesses or those just entering the glass-cutting industry.

Solution: While the initial investment is higher, the increased capabilities and efficiency of 5-axis machines often lead to a quicker return on investment. Businesses can also consider starting with a 3+2 axis machine, which offers many of the benefits of a full 5-axis machine at a lower cost, and upgrade later if needed.

Challenge 3: Operator Training

Operating a 5-axis machine requires a higher level of skill and understanding compared to traditional CNC machines. This can necessitate significant training for existing staff or the hiring of more specialized operators.

Solution: Many machine manufacturers offer comprehensive training programs as part of their package. Additionally, investing in ongoing education and upskilling for operators can pay dividends in terms of machine efficiency and output quality.

Challenge 4: Maintenance and Calibration

With more moving parts and complex geometries, 5-axis machines require more frequent and meticulous maintenance and calibration to ensure ongoing precision.

Solution: Implementing a rigorous preventative maintenance schedule and investing in advanced calibration tools can help ensure the machine remains in optimal condition. Some modern machines also come with built-in calibration and self-diagnostic features, simplifying this process.

By addressing these challenges head-on, businesses can successfully implement 5-axis technology with a CNC shaped glass cutting machine in their glass cutting operations, opening up new possibilities and competitive advantages in the market.

Conclusion

The advent of 5-axis technology in CNC shaped glass cutting machines marks a significant leap forward in glass manufacturing capabilities. By enabling the creation of complex, multi-dimensional shapes with unprecedented precision and efficiency, these machines are opening up new possibilities across various industries.

From architectural marvels to advanced automotive components, the applications of this technology are vast and continually expanding. While implementing 5-axis technology does come with its challenges, the benefits in terms of increased capabilities, improved efficiency, and enhanced product quality make it a worthwhile investment for many businesses in the glass industry.

As this technology continues to evolve, we can expect to see even more innovative applications and further refinements in precision and efficiency. The future of glass cutting is here, and it's shaped by the power of 5-axis CNC technology.

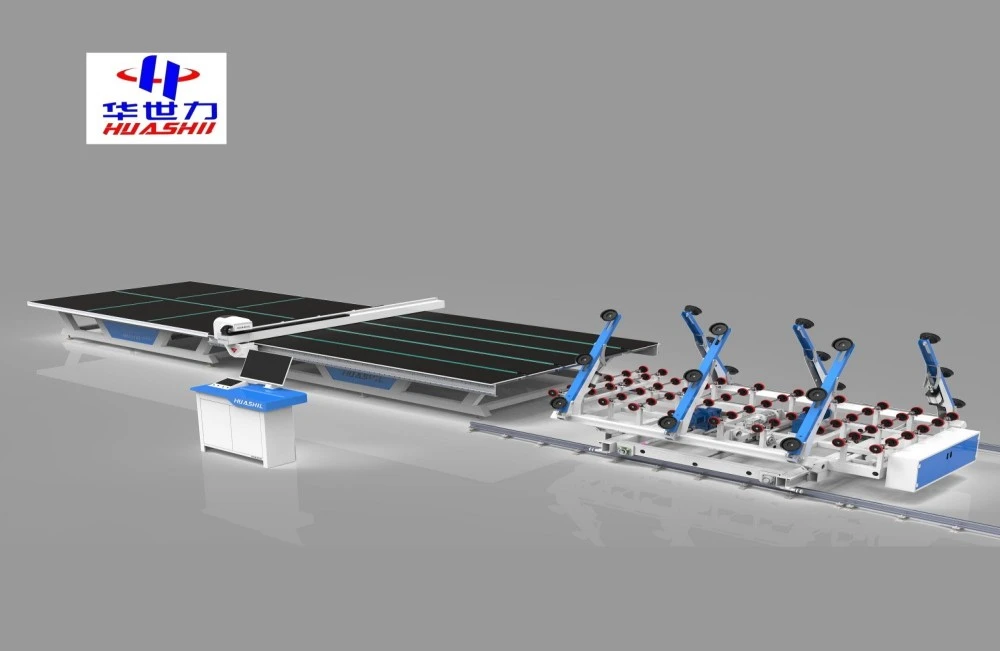

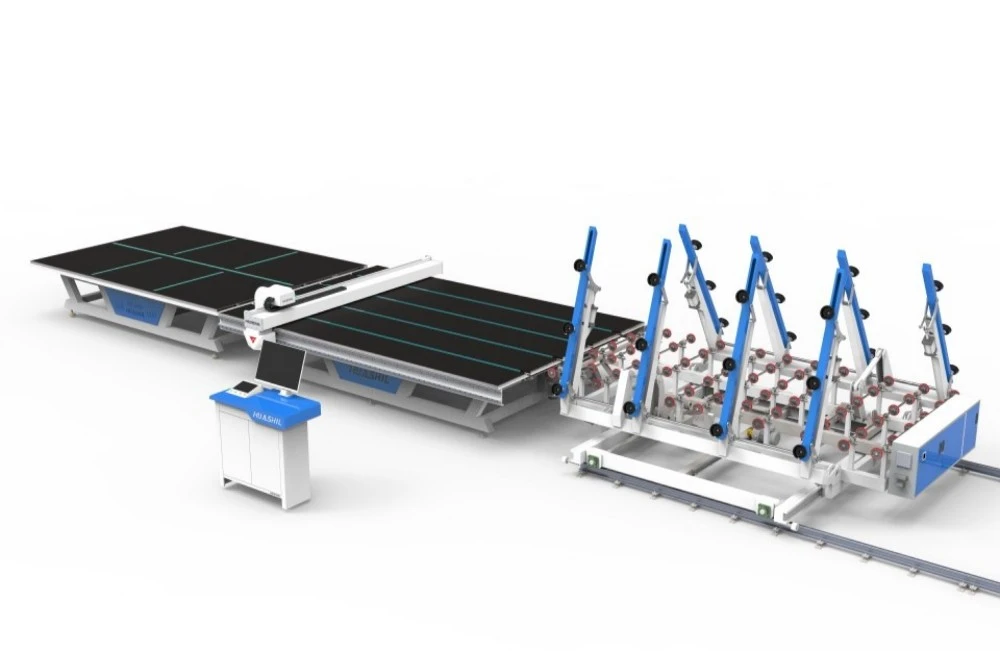

Are you ready to elevate your glass cutting capabilities to new heights? At Shandong Huashil Automation Technology Co., LTD, we specialize in advanced CNC shaped glass cutting machines that harness the power of 5-axis technology. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment make us the ideal partner for businesses looking to stay ahead in the competitive glass industry.

Whether you're an architectural firm seeking to create stunning glass facades, an automotive manufacturer aiming for precision in every component, or a glass artist pushing the boundaries of what's possible, our machines are designed to meet your needs. With Huashil's advanced technique, stable quality, and excellent service, you can trust that you're investing in a solution that will drive your business forward.

FAQ

Q1: How does 5-axis technology improve efficiency in glass cutting?

A: 5-axis technology significantly improves efficiency in glass cutting by reducing the need for multiple setups. Complex shapes that would traditionally require repositioning the glass or changing tools can now be cut in a single operation. This not only saves time but also reduces the risk of errors that can occur during manual repositioning. Additionally, the ability to approach the glass from various angles allows for optimized cutting paths, further improving efficiency and reducing waste.

Q2: What industries benefit most from 5-axis CNC shaped glass cutting machines?

A: While 5-axis CNC shaped glass cutting machines offer benefits across various sectors, some industries that particularly benefit include:

- Architecture: For creating complex structural glass elements and unique facades.

- Automotive: For producing precisely curved windshields and other glass components.

- Aerospace: For manufacturing high-precision glass parts for aircraft and spacecraft.

- Art and Design: For creating intricate glass sculptures and installations.

- Electronics: For cutting specialized glass used in screens and display technologies.

These industries leverage the precision, flexibility, and ability to create complex geometries that 5-axis technology provides.

Advanced CNC Shaped Glass Cutting Machines: Precision Engineering at Its Finest | HUASHIL

Are you ready to revolutionize your glass cutting operations with state-of-the-art technology? Look no further than Shandong Huashil Automation Technology Co., LTD, a leading CNC shaped glass cutting machine supplier. Our advanced 5-axis CNC shaped glass cutting machines offer unparalleled precision, efficiency, and versatility to meet all your glass cutting needs.

With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we understand the unique challenges faced by the glass industry. Our machines are designed to deliver exceptional results, whether you're working on architectural projects, automotive components, or intricate glass art.

Don't let outdated technology hold your business back. Upgrade to a Huashil CNC shaped glass cutting machine and experience the difference that cutting-edge 5-axis technology can make. Our team of experts is ready to guide you through the selection and implementation process, ensuring you get the most out of your investment.

Ready to take the next step? Contact us today at salescathy@sdhuashil.com to learn more about our products and how they can transform your glass cutting operations. Let Huashil be your partner in precision and innovation.

References

1. Johnson, A. (2023). "Advancements in CNC Technology for Glass Manufacturing". Journal of Industrial Automation, 45(3), 278-295.

2. Smith, B. & Lee, C. (2022). "5-Axis Machining: Revolutionizing the Glass Industry". Glass Technology International, 18(2), 62-75.

3. Patel, R. (2023). "Implementing Advanced CNC Systems: Challenges and Solutions". Manufacturing Engineering, 170(4), 89-103.

4. Zhang, L. et al. (2022). "Applications of 5-Axis CNC in Architectural Glass Design". Architectural Science Review, 65(3), 215-230.