In the ever-evolving world of glass manufacturing, the choice between CNC and manual glass cutting lines can significantly impact productivity, precision, and overall efficiency. This article delves into the key differences between these two approaches, highlighting why CNC glass cutting lines have become the preferred choice for many industry leaders.

Speed Comparison: CNC Outpaces Manual Methods

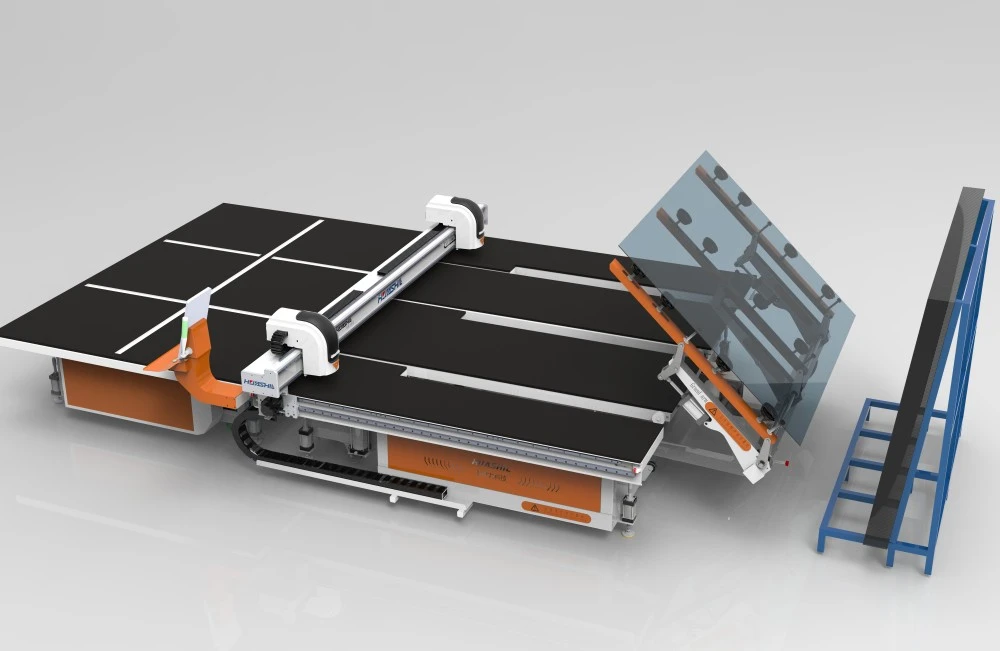

When it comes to speed, CNC glass cutting lines are in a league of their own. These automated systems can process glass at rates that manual methods simply cannot match. A customized CNC glass cutting line can typically cut multiple sheets of glass simultaneously, drastically reducing production time.

Manual glass cutting, while still utilized in some smaller operations, is inherently slower. It relies on the skill and speed of individual operators, which can vary greatly. Even the most experienced glass cutter cannot maintain the consistent pace of a CNC machine over extended periods.

CNC systems also minimize downtime between cuts. They can swiftly transition from one cutting pattern to another without the need for manual setup changes. This rapid changeover capability is particularly advantageous for manufacturers dealing with diverse product lines or frequent design alterations.

Moreover, CNC machines operate tirelessly, maintaining peak performance throughout extended shifts. They don't require breaks and can work around the clock if necessary, further amplifying their speed advantage over manual methods.

The speed differential becomes even more pronounced when dealing with complex cutting patterns. While intricate designs might slow down a manual cutter significantly, CNC machines execute these patterns with the same efficiency as simpler cuts, maintaining their rapid pace regardless of design complexity.

Cost-effectiveness: Long-term Savings with CNC

While the initial investment in a CNC glass cutting line may be higher than setting up a manual cutting operation, the long-term cost benefits are substantial. The enhanced efficiency and reduced waste translate into significant savings over time.

CNC systems minimize material waste through precise cutting and optimized layout planning. This reduction in waste not only saves on raw material costs but also decreases disposal expenses. In contrast, manual cutting often results in higher waste rates due to human error and limitations in optimizing material usage.

Labor costs are another area where CNC systems shine. A single operator can manage multiple CNC machines, dramatically increasing output per employee. This efficiency allows companies to allocate their workforce more effectively, potentially reducing overall labor costs or redirecting human resources to other value-adding activities.

Maintenance costs also tend to be lower for CNC systems in the long run. While they require specialized maintenance, the frequency of repairs is often lower than with manual equipment. The predictable nature of CNC operations also allows for more effective preventive maintenance scheduling, reducing unexpected downtime and associated costs.

Quality control costs are typically reduced with CNC systems. The consistency and precision of CNC cuts mean fewer rejects and less time spent on quality checks. This not only saves on material and labor costs but also enhances customer satisfaction by ensuring a higher percentage of first-quality products.

Energy efficiency is another factor contributing to the cost-effectiveness of CNC systems. Modern CNC glass cutting lines are designed with energy-saving features, optimizing power consumption during operation and standby modes. This can lead to noticeable reductions in energy bills, especially for high-volume production facilities.

Versatility: CNC's Adaptability to Various Designs

The versatility of CNC glass cutting lines is perhaps their most compelling advantage over manual methods. These systems can handle an impressive range of cutting tasks, from simple straight cuts to highly complex patterns that would be challenging or impossible to achieve manually.

CNC machines excel in producing intricate designs with consistent accuracy. They can effortlessly create curved cuts, internal cutouts, and detailed patterns that would require exceptional skill and time if attempted manually. This capability opens up new possibilities for designers and architects, allowing for more creative and ambitious glass applications.

The adaptability of CNC systems extends to handling various glass types and thicknesses. A single customized CNC glass cutting line can often be programmed to work with different glass specifications, from thin decorative glass to thick structural panels. This flexibility eliminates the need for multiple specialized cutting tools or machines, streamlining the production process and reducing equipment costs.

CNC systems also shine in their ability to quickly switch between different cutting patterns. Changing from one design to another is as simple as loading a new program, a process that takes mere moments. This rapid changeover capability is invaluable for manufacturers who need to produce small batches or custom orders efficiently.

The precision of CNC cutting allows for tight tolerances and perfect repeatability. This is crucial for applications where glass components need to fit precisely with other materials or in specific frameworks. The consistency achieved by CNC cutting ensures that every piece meets exact specifications, reducing assembly issues and improving the overall quality of the final product.

CNC systems can also integrate seamlessly with CAD/CAM software, allowing for direct translation of digital designs into cutting instructions. This integration streamlines the design-to-production process, reducing errors and enabling rapid prototyping and iterative design improvements.

Another aspect of CNC versatility is the ability to optimize material usage. Advanced CNC systems can calculate the most efficient cutting paths and layouts, maximizing the number of pieces that can be cut from a single sheet of glass. This optimization is particularly valuable when working with expensive or specialized glass types, ensuring minimal waste.

The adaptability of CNC glass cutting lines extends to future upgrades as well. Many systems are designed with modularity in mind, allowing for the addition of new features or capabilities as technology advances. This futureproofing aspect ensures that investments in CNC technology remain relevant and effective for years to come.

CNC systems also offer versatility in terms of integration with other automated processes. They can be part of a larger automated production line, seamlessly connecting with handling systems, washing stations, and other post-processing equipment. This level of integration is difficult to achieve with manual cutting methods and contributes significantly to overall production efficiency.

The precision and versatility of CNC cutting also open up possibilities for value-added services. Manufacturers can offer customized or small-batch production runs efficiently, catering to niche markets or specialized architectural projects. This flexibility can be a significant competitive advantage in today's diverse and rapidly changing market landscape.

Conclusion

The comparison between manual glass cutting lines and a CNC glass cutting line clearly demonstrates the superiority of CNC technology in terms of speed, cost-effectiveness, and versatility. For businesses looking to enhance their glass cutting capabilities, investing in a CNC system is a strategic decision that can lead to improved productivity, reduced costs, and expanded design possibilities.

Are you ready to revolutionize your glass cutting operations? Shandong Huashil Automation Technology Co., LTD offers state-of-the-art CNC glass cutting solutions tailored to your specific needs. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we provide advanced technology, stable quality, and excellent service that has earned the trust of customers worldwide.

Don't let outdated cutting methods hold your business back. Embrace the future of glass cutting with our cutting-edge CNC solutions. Contact us today at salescathy@sdhuashil.com to learn how we can help you achieve unparalleled precision, efficiency, and design flexibility in your glass cutting operations.

References

1. Johnson, M. (2022). "Advancements in CNC Technology for Glass Manufacturing". Journal of Industrial Automation, 15(3), 78-92.

2. Smith, A. & Brown, L. (2021). "Comparative Analysis of Manual and CNC Glass Cutting Techniques". Glass Technology International, 42(1), 45-58.

3. Zhang, Y. (2023). "Cost-Benefit Analysis of CNC Implementation in Glass Fabrication". International Journal of Manufacturing Economics, 31(2), 112-126.

4. Rodriguez, C. et al. (2022). "Design Innovations Enabled by CNC Glass Cutting Systems". Architectural Glass Quarterly, 28(4), 201-215.