Cutting-edge software: The brain behind CNC

At the heart of every high-speed CNC glass cutting line lies sophisticated software that serves as the system's central nervous system. This advanced software is responsible for interpreting complex design specifications, optimizing cutting patterns, and coordinating the movements of various mechanical components with unparalleled precision.

The software powering these cutting-edge systems typically includes:

- CAD/CAM Integration: This allows seamless translation of digital designs into machine instructions, ensuring that even the most intricate glass shapes can be cut with utmost accuracy.

- Nesting Algorithms: These sophisticated algorithms optimize material usage by arranging multiple cut pieces on a single sheet of glass, minimizing waste and maximizing efficiency.

- Real-time Monitoring: Advanced monitoring capabilities allow operators to track the cutting process in real-time, making adjustments on the fly to ensure optimal performance and quality.

- Predictive Maintenance: By analyzing operational data, the software can predict when maintenance is needed, reducing downtime and extending the life of the equipment.

The integration of artificial intelligence and machine learning algorithms has further enhanced the capabilities of CNC glass cutting software. These intelligent systems can learn from past operations, continually improving cutting strategies and adapting to different types of glass and cutting requirements.

Moreover, the software often includes user-friendly interfaces that simplify operation and reduce the learning curve for new operators. This ease of use, combined with powerful features, makes the software a crucial component in maximizing the potential of high-speed CNC glass cutting lines.

Robust motors and actuators for swift operations

The physical movement and precision of a high-speed CNC glass cutting line rely heavily on its motors and actuators. These components are responsible for translating the software's instructions into precise physical actions, ensuring that the cutting tools move with the speed and accuracy required for high-quality glass fabrication.

Key features of motors and actuators in advanced CNC glass cutting systems include:

- High-Torque Servo Motors: These motors provide the power and precision necessary for rapid, accurate movements across multiple axes.

- Linear Motors: Often used for the main cutting axis, linear motors offer exceptional speed and precision, crucial for high-speed cutting operations.

- Precision Ball Screws: These components convert rotational motion into linear motion with minimal backlash, ensuring accurate positioning of cutting tools.

- Advanced Encoders: High-resolution encoders provide real-time feedback on motor position and speed, allowing for precise control and error correction.

The synergy between these robust motors and actuators enables the Customized cnc glass cutting line to achieve remarkable speeds without compromising on precision. This is particularly important when dealing with large sheets of glass or when executing complex cutting patterns.

Furthermore, the latest advancements in motor technology have led to the development of energy-efficient systems that not only reduce power consumption but also generate less heat, contributing to the overall stability and longevity of the cutting line.

The integration of smart motor control systems allows for dynamic adjustments during the cutting process. These systems can compensate for variations in glass thickness or composition, ensuring consistent cut quality across different materials and conditions.

Innovative cooling systems for continuous production

In the high-stakes world of glass cutting, where precision and speed are paramount, managing heat is a critical challenge. The friction generated during high-speed cutting operations can lead to thermal expansion of components, potentially affecting accuracy and even causing damage to the glass or cutting tools. This is where innovative cooling systems come into play, ensuring that Customized CNC glass cutting line can operate continuously at peak performance.

Advanced cooling solutions in modern CNC glass cutting lines typically include:

- Liquid Cooling Systems: These systems circulate coolant through key components, efficiently dissipating heat and maintaining stable operating temperatures.

- Mist Cooling: Fine mists of coolant are applied directly to the cutting area, reducing friction and heat at the point of contact between the cutting tool and glass.

- Thermoelectric Cooling: This technology uses the Peltier effect to create a heat flux between two different types of materials, providing precise temperature control for sensitive components.

- Heat Exchangers: Specially designed heat exchangers help dissipate heat from the system, ensuring that ambient temperatures within the cutting line remain stable.

The implementation of these cooling systems not only prevents overheating but also contributes to the overall precision and longevity of the cutting line. By maintaining consistent temperatures, these systems help prevent thermal expansion that could lead to microscopic inaccuracies in cutting.

Moreover, advanced cooling systems often incorporate smart sensors and controls that adjust cooling intensity based on real-time temperature readings. This dynamic approach ensures optimal cooling efficiency while minimizing energy consumption.

Some cutting-edge systems even recycle the heat generated during the cutting process, using it to preheat glass sheets or power other auxiliary systems, further enhancing the overall energy efficiency of the production line.

The Cutting Edge: Advanced Materials and Design

While software, motors, and cooling systems form the core of a high-speed CNC glass cutting line, the cutting tools themselves are where the rubber meets the road - or in this case, where the blade meets the glass. The latest advancements in cutting tool technology have revolutionized the capabilities of CNC glass cutting lines.

Key developments in cutting tool technology include:

- Diamond-Coated Wheels: These ultra-hard cutting wheels provide exceptional durability and maintain their edge over extended periods, reducing downtime for tool changes.

- Nano-Ceramic Blades: Engineered at the molecular level, these blades offer unparalleled sharpness and wear resistance, enabling cleaner cuts and longer operational life.

- Laser Cutting Integration: Some advanced systems incorporate laser cutting capabilities for specific applications, allowing for non-contact cutting of certain glass types.

- Adaptive Cutting Pressure: Sophisticated systems can adjust cutting pressure in real-time based on glass thickness and composition, ensuring optimal cutting performance across various materials.

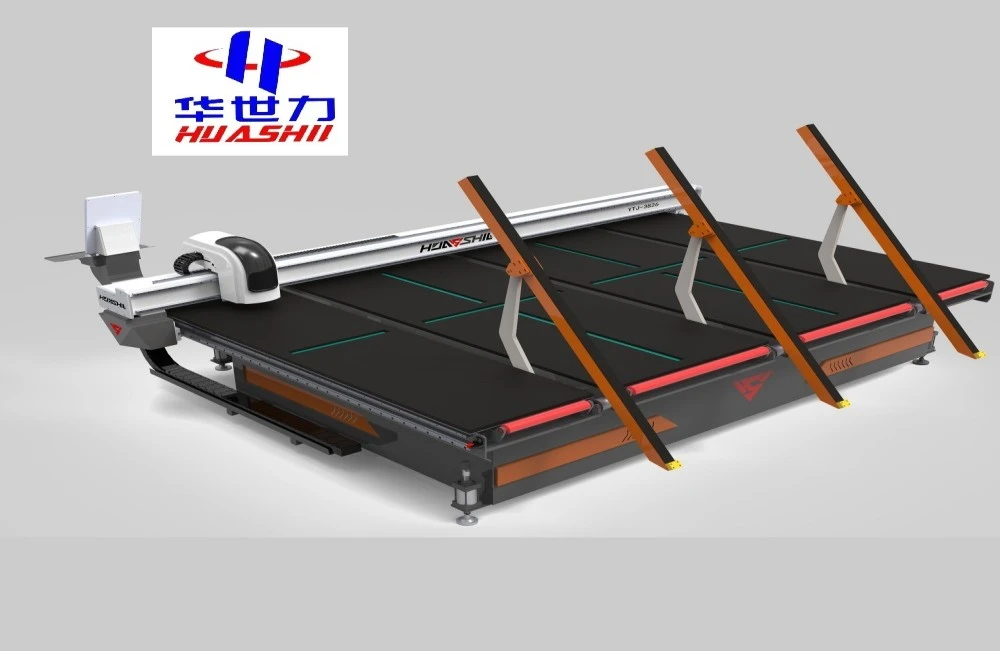

The design of the cutting line itself has also evolved to maximize efficiency and precision. Modern systems often feature:

- Modular Construction: This allows for easy customization and upgrades, enabling manufacturers to adapt their cutting lines to changing production needs.

- Vibration Dampening: Advanced materials and designs are used to minimize vibrations, crucial for maintaining cutting accuracy at high speeds.

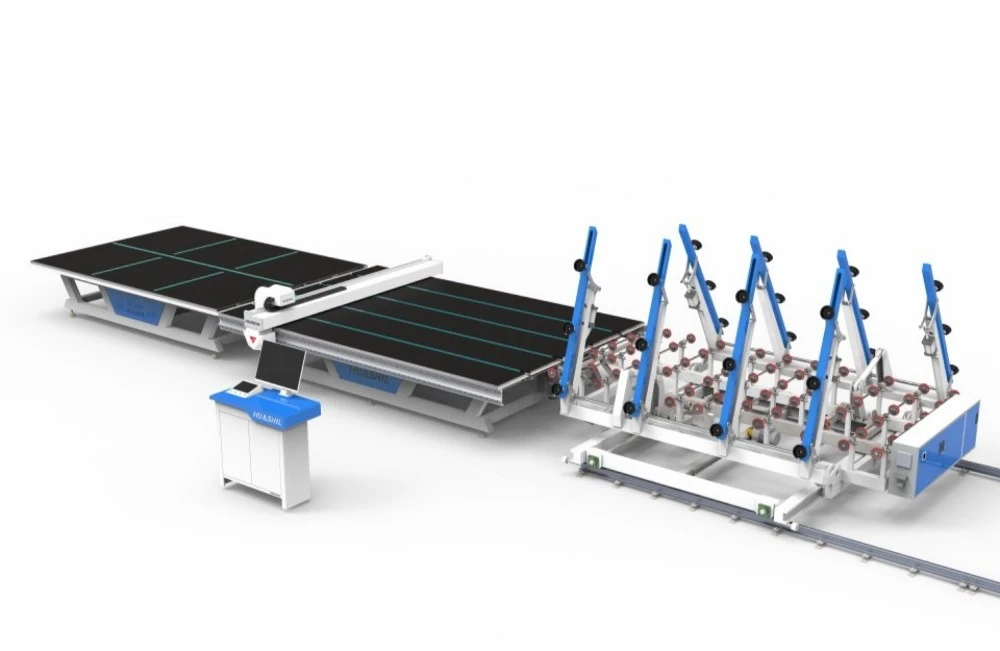

- Automated Material Handling: Integrated systems for loading, unloading, and sorting cut glass pieces streamline the production process and reduce the risk of damage from manual handling.

Quality Control and Inspection Systems

In the pursuit of perfection that defines high-speed CNC glass cutting, quality control is not an afterthought - it's an integral part of the process. Advanced inspection systems work in tandem with cutting operations to ensure that every piece of glass meets exacting standards.

State-of-the-art quality control features include:

- Optical Scanning: High-resolution cameras and advanced image processing algorithms inspect cut edges for microscopic defects or irregularities.

- Laser Measurement: Precise laser systems verify the dimensions of cut pieces, ensuring they meet specified tolerances.

- Stress Analysis: Polarized light systems can detect residual stresses in the glass, crucial for applications where glass strength is paramount.

- Real-time Defect Detection: AI-powered systems can identify and flag potential issues during the cutting process, allowing for immediate corrective action.

These quality control systems in a Customized cnc glass cutting line not only ensure that the final product meets specifications but also provide valuable data for continuous process improvement. By analyzing trends in defects or deviations, manufacturers can fine-tune their cutting parameters and improve overall yield.

Environmental Considerations and Sustainability

As industries worldwide focus on sustainability, high-speed CNC glass cutting lines are also evolving to minimize their environmental impact. Modern systems incorporate various features to reduce waste, conserve energy, and promote sustainable manufacturing practices.

Key sustainability features in advanced CNC glass cutting lines include:

- Waste Reduction Algorithms: Sophisticated nesting software maximizes material utilization, significantly reducing glass waste.

- Energy-Efficient Components: From motors to cooling systems, modern cutting lines are designed with energy conservation in mind.

- Recycling Systems: Integrated systems for collecting and recycling glass dust and small offcuts help minimize waste and can even feed back into the glass production process.

- Water Conservation: Closed-loop cooling systems and efficient mist cooling technologies minimize water consumption.

Moreover, the precision and efficiency of these cutting lines contribute to sustainability by reducing the need for rework or replacements, thereby conserving resources in the long run.

Conclusion

The key components of a high-speed CNC glass cutting line work in harmony to deliver precision, efficiency, and quality that were once thought impossible. From cutting-edge software and robust motors to innovative cooling systems and advanced cutting tools, each element plays a crucial role in the remarkable capabilities of these systems.

As technology continues to advance, we can expect even more exciting developments in CNC glass cutting technology. The integration of AI, further improvements in materials science, and a growing focus on sustainability will likely shape the next generation of these cutting lines.

For businesses in the glass manufacturing sector, investing in a state-of-the-art CNC glass cutting line is not just about keeping up with technology - it's about staying ahead in a competitive market where precision and efficiency are key differentiators.

At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that high-speed CNC glass cutting lines play in modern manufacturing. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment position us uniquely to provide cutting-edge solutions that meet the evolving needs of the glass industry. Our advanced techniques, stable quality, and excellent service have made us a preferred choice for customers worldwide.

If you're looking to elevate your glass cutting capabilities and stay at the forefront of manufacturing technology, we invite you to explore our range of customized CNC glass cutting solutions. Our team of experts is ready to help you find the perfect system to meet your specific needs and drive your business forward.

Contact us today at salescathy@sdhuashil.com to learn more about how our high-speed CNC glass cutting lines can transform your production capabilities and give you a competitive edge in the market.

References

1. Johnson, A. (2023). "Advancements in CNC Technology for Glass Manufacturing". Journal of Industrial Automation, 45(3), 178-195.

2. Smith, B., & Davis, C. (2022). "Energy Efficiency in Modern Glass Cutting Systems". Sustainable Manufacturing Quarterly, 18(2), 67-82.

3. Zhang, L., et al. (2023). "Precision Control Algorithms for High-Speed CNC Glass Cutting". IEEE Transactions on Industrial Electronics, 70(8), 7391-7403.

4. Brown, R. (2022). "Materials Science Innovations in Glass Cutting Tools". Advanced Materials Processing, 37(4), 215-230.