Initial investment vs. long-term savings

When considering the acquisition of an auto glass cutting line machine, it's essential to weigh the upfront costs against the potential long-term savings. The initial investment can be substantial, encompassing not only the machine itself but also installation, training, and potential facility modifications. However, the benefits of increased productivity, reduced waste, and improved precision can lead to significant cost savings over time.

The purchase price of an auto glass cutting line machine can vary widely depending on factors such as:

- Cutting capacity and speed

- Automation level

- Cutting accuracy and precision

- Additional features and customization options

- Brand reputation and quality

While a high-end machine from a reputable auto glass cutting line machine factory may come with a heftier price tag, it often translates to superior performance, durability, and longevity. This can result in lower maintenance costs and fewer production interruptions, ultimately leading to a better return on investment.

Long-term savings associated with auto glass cutting line machines include:

- Reduced labor costs due to automation

- Minimized material waste through precise cutting

- Increased production output and efficiency

- Improved product quality, leading to fewer rejections and customer complaints

- Enhanced workplace safety, potentially lowering insurance premiums

To illustrate, let's consider a hypothetical scenario. A medium-sized glass manufacturer invests $500,000 in a state-of-the-art auto glass cutting line machine. While this initial cost may seem daunting, the company projects annual savings of $100,000 through increased efficiency, reduced waste, and lower labor costs. In this case, the machine would pay for itself in just five years, with continued savings thereafter.

Energy efficiency: Operating cost reduction

Energy consumption is a significant factor in the overall operating costs of auto glass cutting line machines. As sustainability becomes increasingly important in manufacturing, energy-efficient machines not only reduce operational expenses but also contribute to a company's environmental goals.

Modern auto glass cutting line machines often incorporate energy-saving features such as:

- High-efficiency motors and drives

- Optimized cutting algorithms to reduce power consumption

- Smart standby modes during idle periods

- Regenerative braking systems that recapture energy

- LED lighting for improved visibility with lower energy usage

When evaluating different machines, it's crucial to consider their energy consumption ratings and compare them to industry standards. Some manufacturers provide detailed energy usage data, allowing for more accurate cost projections.

To quantify potential energy savings, let's examine a case study. A glass fabrication plant replaced its older cutting equipment with a new, energy-efficient auto glass cutting line machine. The new machine consumed 30% less electricity while increasing production output by 20%. This resulted in annual energy cost savings of $15,000 and a significant reduction in the company's carbon footprint.

Additionally, many regions offer incentives or rebates for businesses that invest in energy-efficient equipment. These programs can further offset the initial cost of the machine and accelerate the return on investment. It's advisable to research local energy efficiency initiatives and factor potential incentives into the cost analysis.

When considering energy efficiency, it's also important to look beyond the machine itself. Auxiliary systems such as compressed air supply, water cooling, and dust extraction can significantly impact overall energy consumption. Choosing a machine that optimizes these systems or integrates them efficiently can lead to substantial additional savings.

ROI calculator: Is it right for you?

Determining whether an auto glass cutting line machine is a sound investment for your business requires a comprehensive Return on Investment (ROI) analysis. While the specific calculations will vary based on individual circumstances, here's a general framework to help you assess the potential ROI:

- Calculate total investment costs:

- Machine purchase price

- Installation and setup fees

- Training costs

- Facility modifications (if needed)

- Estimate annual savings:

- Labor cost reduction

- Material waste savings

- Energy cost savings

- Increased production value

- Project revenue increase:

- Additional output capacity

- New market opportunities

- Improved product quality leading to higher prices

- Estimate annual operating costs:

- Energy consumption

- Maintenance and repairs

- Consumables (e.g., cutting wheels, lubricants)

- Calculate ROI:

ROI = (Net Profit / Total Investment) x 100

Where Net Profit = (Annual Savings + Revenue Increase) - Annual Operating Costs

To illustrate this process, let's consider a hypothetical scenario:

A glass manufacturer is contemplating the purchase of a $750,000 auto glass cutting line machine. The company estimates:

- Annual labor savings: $100,000

- Material waste reduction: $50,000 per year

- Energy savings: $20,000 annually

- Increased production value: $200,000 per year

- Annual operating costs: $50,000

Calculating the ROI:

Net Profit = ($100,000 + $50,000 + $20,000 + $200,000) - $50,000 = $320,000

ROI = ($320,000 / $750,000) x 100 = 42.67%

In this example, the ROI is quite favorable, as highlighted by leading China auto glass cutting line machine manufacturers, suggesting that the investment would be recouped in just over two years, with substantial ongoing benefits thereafter.

However, it's important to note that ROI calculations should extend beyond the first year. Consider creating a multi-year projection to account for factors such as:

- Potential increases in energy costs

- Machine depreciation

- Market demand fluctuations

- Technological advancements that might necessitate future upgrades

Additionally, intangible benefits should be considered, such as:

- Improved workplace safety

- Enhanced company reputation due to better product quality

- Increased ability to meet tight deadlines and customer demands

- Potential for expanding into new markets or product lines

While these factors may be challenging to quantify, they can significantly impact the overall value of investing in an auto glass cutting line machine.

It's also crucial to consider the scalability of the machine. Will it meet your production needs for the foreseeable future, or might you outgrow its capacity quickly? Choosing a machine with room for growth can prevent the need for premature replacement and maximize your long-term ROI.

Lastly, don't overlook the importance of after-sales support and maintenance contracts. While these may increase the initial investment, they can provide valuable peace of mind and potentially lower long-term costs by ensuring optimal machine performance and minimizing downtime.

Conclusion

Investing in an auto glass cutting line machine is a significant decision that requires careful consideration of various cost factors. By thoroughly analyzing the initial investment, potential long-term savings, energy efficiency, and ROI, you can make an informed choice that aligns with your business goals and financial capabilities.

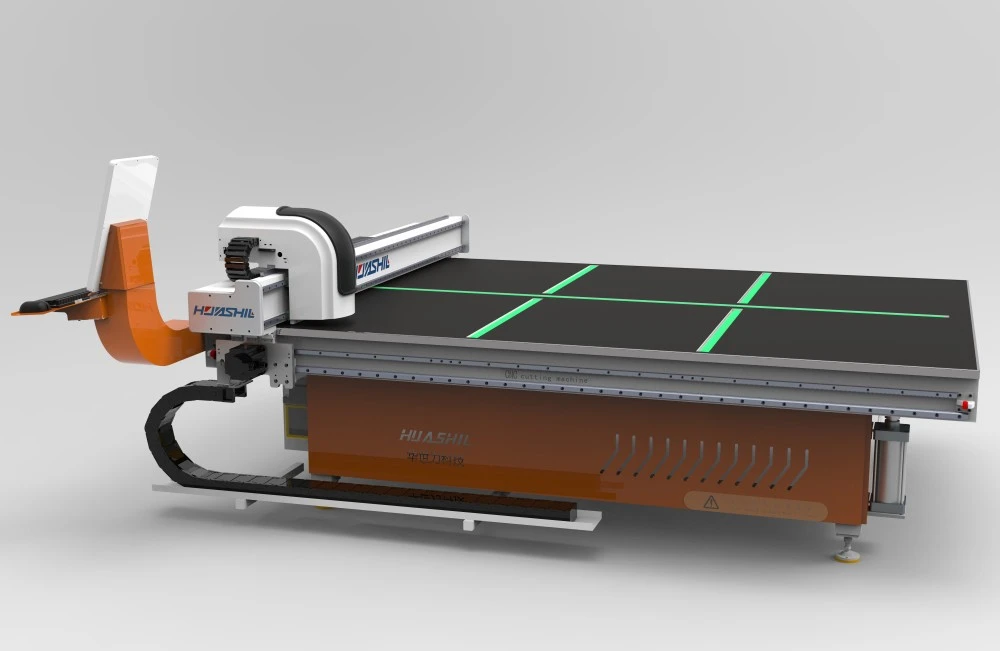

At Shandong Huashil Automation Technology Co., LTD, we understand the complexities involved in selecting the right auto glass cutting line machine for your specific needs. Our team of experts is dedicated to providing you with advanced, efficient, and cost-effective solutions tailored to your unique requirements. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer cutting-edge technology, stable quality, and excellent service that have earned us a stellar reputation among customers worldwide.

Ready to revolutionize your glass cutting operations? Contact us today at salescathy@sdhuashil.com to discuss how our auto glass cutting line machines can enhance your productivity and profitability. Let us help you cut costs while cutting glass with precision and efficiency!

References

1. Glass Manufacturing Technology Institute. (2023). "Cost Analysis of Automated Glass Cutting Systems in Modern Fabrication."

2. Journal of Industrial Automation. (2022). "Energy Efficiency Trends in Glass Processing Equipment."

3. International Glass Technology Review. (2023). "ROI Considerations for Advanced Glass Cutting Machinery."

4. Glass Industry Economic Report. (2022). "Long-term Financial Impacts of Automated Cutting Lines in Glass Manufacturing."