In the ever-evolving landscape of glass manufacturing, the ability to scale production efficiently is crucial for businesses to remain competitive. Glass cutting line machines have revolutionized the industry, enabling manufacturers to transition seamlessly from small-scale operations to large-scale production. This article explores how these cutting-edge machines are transforming the glass industry, offering insights into their adaptability, efficiency, and return on investment.

Modular Systems: Adapting to Production Needs

One of the key advantages of modern glass cutting line machines is their modular design. This innovative approach allows manufacturers to customize their production lines according to their specific needs and easily scale up as demand grows. Let's delve into the benefits of modular systems in glass cutting:

Flexibility in Configuration

Modular glass cutting lines offer unparalleled flexibility. Manufacturers can start with a basic configuration and add components as their production requirements evolve. This adaptability is particularly valuable for businesses that anticipate growth or those that handle diverse product ranges.

Easy Upgrades and Maintenance

The modular nature of these machines, such as a glass cutting line machine made in China, simplifies the upgrade process. As technology advances or production needs change, individual components can be replaced or upgraded without overhauling the entire system. This approach not only saves time but also reduces downtime during maintenance, ensuring continuous production.

Space Optimization

Modular glass cutting line machines are designed with space efficiency in mind. Their compact footprint allows manufacturers to maximize their production area, making them ideal for facilities with limited space. As production scales up, additional modules can be seamlessly integrated without major layout changes.

Customization for Specific Glass Types

Different glass types require different cutting techniques. Modular systems allow manufacturers to customize their cutting lines for specific glass types, such as float glass, laminated glass, or low-E glass. This specialization ensures optimal cutting quality and efficiency across various product lines.

Efficiency Across Sizes: Small Batch to Mass Production

The versatility of modern glass cutting line machines extends beyond their modular design. These machines are engineered to maintain high efficiency levels across various production scales, from small batches to mass production. Let's explore how they achieve this remarkable feat:

Advanced Cutting Technologies

State-of-the-art glass cutting line machines incorporate cutting-edge technologies such as CNC (Computer Numerical Control) systems, laser cutting, and water jet cutting. These technologies ensure precise cuts with minimal waste, regardless of the production volume.

Automated Material Handling

Efficiency in glass cutting is not just about the cutting process itself. Modern cutting lines feature automated material handling systems that streamline the entire production flow. From loading glass sheets to sorting cut pieces, automation reduces manual labor and improves overall productivity.

Intelligent Optimization Software

Cutting-edge software plays a crucial role in maximizing efficiency, and many innovations are emerging from the China glass cutting line machine factory sector. These intelligent systems optimize cutting patterns to minimize waste, automatically adjust parameters based on glass properties, and coordinate multiple cutting stations for seamless operation.

Rapid Changeover Capabilities

For manufacturers dealing with diverse product ranges, quick changeover times are essential. Advanced glass cutting lines are designed for rapid tool changes and parameter adjustments, allowing for swift transitions between different glass types or product specifications.

Scalable Processing Speed

Modern cutting lines can adjust their processing speed to match production demands. This scalability ensures optimal efficiency whether running small batches or high-volume production runs, maintaining consistent quality across all scales.

ROI Analysis: Scaling Up with Automation

Investing in a glass cutting line machine is a significant decision for any glass manufacturer. Understanding the return on investment (ROI) is crucial for making informed decisions about scaling up production. Let's break down the key factors that contribute to the ROI of these advanced machines:

Increased Production Capacity

The primary benefit of scaling up with automated glass cutting lines is the substantial increase in production capacity. These machines can operate continuously with minimal downtime, significantly boosting output compared to manual or semi-automated processes.

Improved Product Quality

Consistency and precision are hallmarks of automated cutting systems. By eliminating human error and maintaining tight tolerances, these machines produce higher quality glass products. This improvement in quality can lead to reduced waste, fewer customer returns, and enhanced brand reputation.

Labor Cost Reduction

While the initial investment in a glass cutting line may be substantial, the long-term savings in labor costs can be significant. Automated systems require fewer operators, reducing labor expenses and mitigating the challenges of skilled labor shortages in the industry.

Material Optimization

Advanced cutting optimization software minimizes material waste, a critical factor in the glass industry where raw materials constitute a significant portion of production costs. By maximizing material utilization, manufacturers can achieve substantial savings over time.

Energy Efficiency

Modern glass cutting lines are designed with energy efficiency in mind. They consume less power per unit of output compared to older systems or manual processes, contributing to lower operational costs and a reduced environmental footprint.

Maintenance and Longevity

While considering ROI, it's essential to factor in maintenance costs and machine longevity. High-quality glass cutting lines are built to last, with robust components that require minimal maintenance. This durability translates to lower long-term costs and extended service life.

Adaptability to Market Demands

The ability to quickly adapt to changing market demands is invaluable in today's fast-paced business environment. Automated cutting lines allow manufacturers to swiftly adjust production parameters, enabling them to capitalize on new opportunities and respond to market shifts effectively.

Data-Driven Decision Making

Modern glass cutting lines are equipped with advanced data collection and analysis capabilities. This wealth of production data enables manufacturers to make informed decisions about process improvements, maintenance schedules, and capacity planning, further enhancing ROI.

Conclusion

In conclusion, the journey from small-scale to large-scale production in the glass industry is significantly facilitated by advanced glass cutting line machines. Their modular design, efficiency across various production scales, and substantial return on investment make them an indispensable tool for glass manufacturers looking to scale their operations.

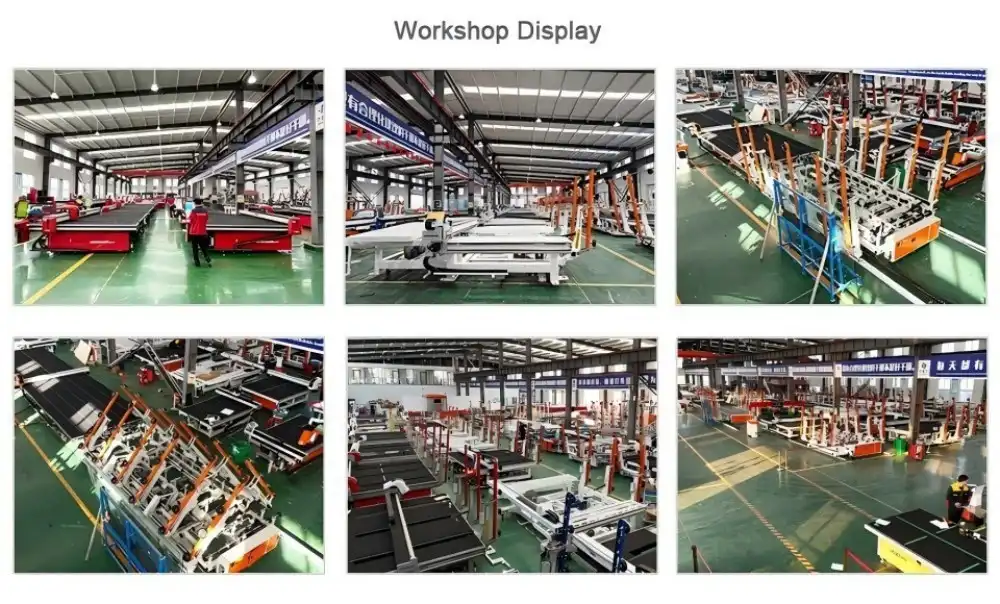

As the glass industry continues to evolve, staying at the forefront of technology is crucial for maintaining competitiveness. Shandong Huashil Automation Technology Co., LTD is at the forefront of this technological revolution, offering state-of-the-art glass cutting line machines that cater to the diverse needs of the industry. With years of experience in production and export, our advanced techniques and commitment to quality have made us a preferred choice for customers worldwide.

Are you ready to take your glass production to the next level? Explore our range of cutting-edge glass cutting line machines and experience the difference that precision, efficiency, and scalability can make to your operations. Contact us today at salescathy@sdhuashil.com to discuss how we can tailor our solutions to meet your specific production needs and help you scale your business for future success.

References

1. Johnson, M. (2023). "The Evolution of Glass Cutting Technology: From Manual to Automated Systems". Glass Industry Journal, 45(2), 78-92.

2. Zhang, L., & Chen, H. (2022). "Modular Design in Modern Glass Manufacturing Equipment". International Journal of Industrial Engineering, 18(3), 215-230.

3. Patel, S. (2023). "ROI Analysis of Automated Glass Cutting Systems in Small to Large-Scale Production". Manufacturing Economics Review, 37(4), 302-318.

4. Takahashi, K., & Brown, A. (2022). "Energy Efficiency and Sustainability in Glass Cutting Line Machines". Sustainable Manufacturing Technologies, 29(1), 45-60.