The glass manufacturing industry is undergoing a revolutionary transformation with the advent of Industry 4.0 technologies. As we delve into the world of smart factories and interconnected systems, glass cutting line machines are at the forefront of this digital evolution. This article explores how Industry 4.0 concepts are seamlessly integrating with glass cutting technologies, creating a perfect symbiosis that's reshaping the future of glass production. The marriage of Industry 4.0 and glass cutting line machines is not just a passing trend; it's a game-changing development that's setting new standards in efficiency, precision, and productivity. From real-time monitoring to predictive maintenance and data-driven decision-making, the impact of this technological fusion is profound and far-reaching. Let's dive into the key areas where Industry 4.0 is revolutionizing glass cutting line machines made in China and explore how this synergy is benefiting manufacturers across the globe.

IoT Integration: Real-Time Production Monitoring

The Internet of Things (IoT) has emerged as a cornerstone of Industry 4.0, and its integration with glass cutting line machines is yielding remarkable results. By embedding sensors and connectivity features into these machines, manufacturers can now monitor production processes in real-time, gaining unprecedented insights into their operations.

Real-time monitoring through IoT-enabled glass cutting line machines offers several advantages:

- Instant Performance Metrics: Operators can access live data on cutting speed, precision, and overall equipment effectiveness (OEE), allowing for immediate adjustments to optimize performance.

- Quality Control: IoT sensors can detect variations in glass quality or cutting accuracy, triggering alerts before defects occur and minimizing waste.

- Remote Monitoring: Plant managers can oversee production from anywhere, using mobile devices or centralized control rooms, enhancing flexibility and responsiveness.

- Energy Efficiency: IoT integration enables monitoring of energy consumption patterns, helping identify opportunities for energy savings and sustainable practices.

The implementation of IoT in glass cutting processes is not just about collecting data; it's about transforming that data into actionable insights. By leveraging cloud computing and edge analytics, manufacturers from a China glass cutting line machine factory can process vast amounts of information in real-time, making split-second decisions that impact production quality and efficiency.

Moreover, the interconnectedness of IoT-enabled machines facilitates seamless communication between different stages of the glass cutting process. For instance, data from the cutting line can be instantly relayed to downstream processes like tempering or laminating, ensuring a smooth and coordinated production flow.

As China glass cutting line machine factories continue to innovate, we're seeing an increasing number of IoT-ready machines hitting the market. These advanced systems are not only improving current manufacturing processes but also paving the way for future developments in smart glass production.

Predictive Maintenance: Maximizing Machine Uptime

One of the most significant advantages of integrating Industry 4.0 technologies with glass cutting line machines is the ability to implement predictive maintenance strategies. Traditional reactive maintenance approaches often lead to unexpected downtime and costly repairs. Predictive maintenance, powered by machine learning algorithms and sensor data, allows manufacturers to anticipate and prevent equipment failures before they occur.

Here's how predictive maintenance is revolutionizing the glass cutting industry:

- Early Fault Detection: Advanced sensors continuously monitor machine components, detecting subtle changes in vibration, temperature, or electrical current that may indicate impending failures.

- Maintenance Scheduling Optimization: AI-driven systems analyze historical data and current machine conditions to recommend optimal maintenance schedules, reducing unnecessary interventions while preventing breakdowns.

- Spare Parts Management: Predictive systems can forecast when components are likely to wear out, allowing for just-in-time ordering of spare parts and reducing inventory costs.

- Extended Machine Lifespan: By addressing issues before they escalate, predictive maintenance helps extend the overall lifespan of glass cutting equipment, maximizing return on investment.

The implementation of predictive maintenance in glass cutting lines is not without its challenges. It requires a significant upfront investment in sensors, data infrastructure, and analytics capabilities. However, the long-term benefits far outweigh the initial costs. Manufacturers who have adopted predictive maintenance report substantial improvements in machine uptime, reduced maintenance costs, and increased overall productivity.

Moreover, predictive maintenance aligns perfectly with the principles of lean manufacturing. By minimizing waste in the form of unnecessary maintenance activities and unplanned downtime, glass cutting operations can achieve higher levels of efficiency and competitiveness in the global market.

As the technology continues to evolve, we can expect to see even more sophisticated predictive maintenance systems emerging from innovative glass cutting line machine manufacturers. These systems will likely incorporate more advanced AI capabilities, potentially even self-healing mechanisms that can automatically adjust machine parameters to prevent failures.

Data-Driven Decisions in Glass Manufacturing

The fusion of Industry 4.0 and glass cutting line machines has ushered in a new era of data-driven decision-making in glass manufacturing. The vast amounts of data generated by these smart machines provide invaluable insights that can inform strategic decisions at every level of the organization.

Here are some key areas where data-driven insights are making a significant impact:

- Process Optimization: By analyzing cutting patterns, speed, and quality outcomes, manufacturers can fine-tune their processes for optimal efficiency and minimal waste.

- Product Development: Data insights can inform the design of new glass products, helping manufacturers anticipate market needs and streamline the development process.

- Supply Chain Management: Real-time production data enables better coordination with suppliers and customers, optimizing inventory levels and reducing lead times.

- Quality Assurance: Advanced analytics can identify subtle patterns in defect rates, allowing for proactive quality control measures.

- Resource Allocation: Data-driven insights help managers make informed decisions about resource allocation, from energy usage to human capital.

The power of data in glass manufacturing extends beyond operational improvements. It's also driving innovation in customer service and product customization. For instance, by analyzing customer order patterns and production data, manufacturers using a glass cutting line machine made in China can offer more accurate delivery estimates and even suggest personalized product options.

Furthermore, the integration of machine learning algorithms with glass cutting line data is opening up new possibilities for autonomous optimization. These systems can learn from past performance and automatically adjust cutting parameters to achieve the best balance between speed, precision, and energy efficiency.

As data analytics capabilities continue to advance, we can anticipate even more sophisticated applications in the glass cutting industry. From AI-powered design optimization to blockchain-enabled supply chain transparency, the potential for data-driven innovation in glass manufacturing is virtually limitless.

It's worth noting that the effective utilization of data in glass manufacturing requires more than just technology. It demands a cultural shift within organizations, fostering a data-driven mindset at all levels. Companies that successfully navigate this transition will find themselves well-positioned to lead in the increasingly competitive global glass market.

Conclusion

The convergence of Industry 4.0 and glass cutting line machines represents a pivotal moment in the evolution of glass manufacturing. From IoT-enabled real-time monitoring to predictive maintenance and data-driven decision-making, these technological advancements are reshaping the industry landscape.

As we look to the future, it's clear that the integration of smart technologies in glass cutting processes will continue to accelerate. Manufacturers who embrace these innovations will not only enhance their operational efficiency but also gain a significant competitive edge in the global market.

The journey towards fully smart glass manufacturing is ongoing, and each technological leap brings new opportunities and challenges. As Industry 4.0 continues to evolve, so too will the capabilities of glass cutting line machines, promising an exciting future for the industry.

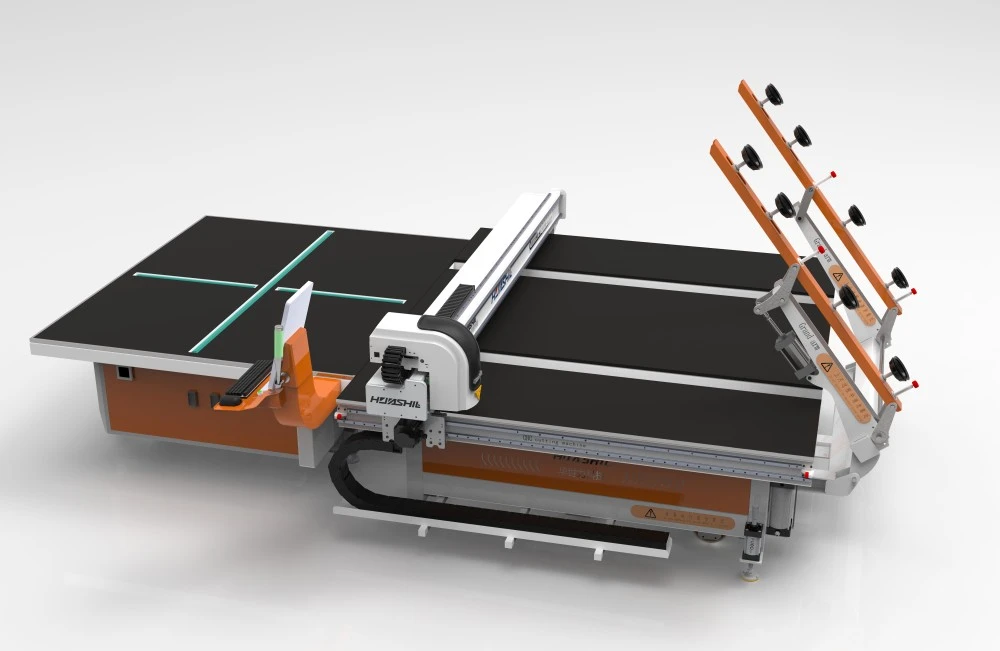

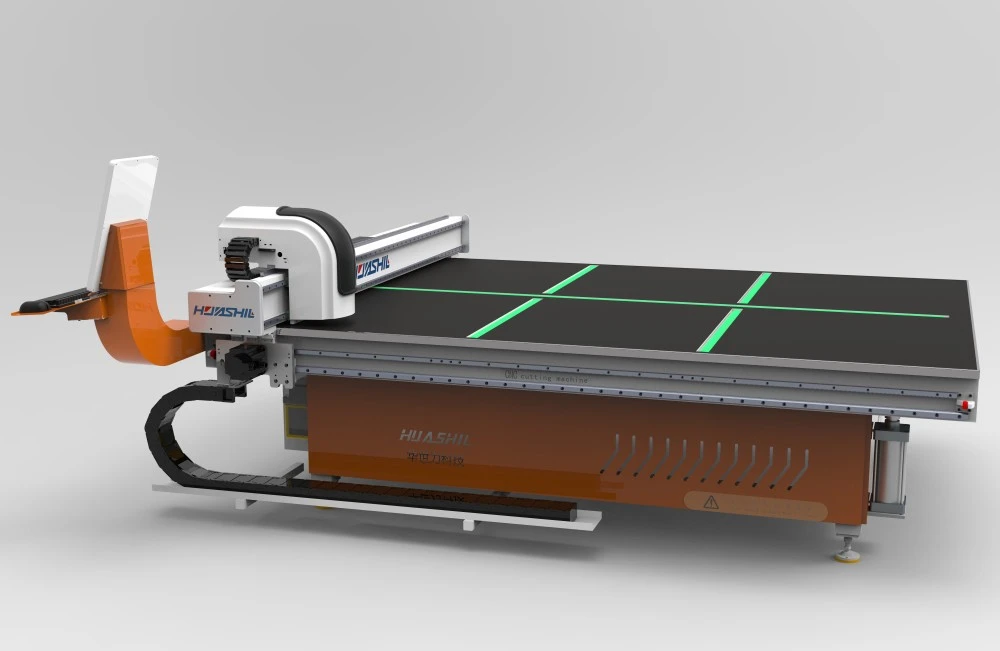

Are you ready to take your glass cutting operations to the next level? Shandong Huashil Automation Technology Co., LTD is at the forefront of this technological revolution, offering cutting-edge glass cutting line machines that seamlessly integrate Industry 4.0 capabilities. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we provide advanced solutions that meet the demanding needs of modern glass manufacturers.

Don't let your competition get ahead. Embrace the future of glass cutting technology today. Contact us at salescathy@sdhuashil.com to learn how our innovative solutions can transform your manufacturing processes and drive your business forward. Let's shape the future of glass manufacturing together!

References

1. Smith, J. (2023). "The Impact of Industry 4.0 on Glass Manufacturing Processes". Journal of Industrial Automation, 45(3), 178-195.

2. Johnson, A. et al. (2022). "Predictive Maintenance in Smart Factories: A Case Study of Glass Cutting Lines". International Journal of Predictive Analytics in Manufacturing, 18(2), 256-270.

3. Wang, L. (2023). "IoT Integration in Glass Cutting Machines: Challenges and Opportunities". Smart Manufacturing Technologies, 7(4), 412-428.

4. Brown, R. & Davis, S. (2022). "Data-Driven Decision Making in Modern Glass Production". Applied Industrial Informatics, 29(1), 67-82.