Edge Clarity: Machine vs. Manual Cutting

The edge quality of glass plays a crucial role in its overall optical performance. Traditional manual cutting methods, while skilled, often result in inconsistencies that can affect the glass's clarity and strength. Glass cutting line machines have transformed this aspect of production, offering several advantages:

- Precision Cutting: Automated machines from a China glass cutting line machine factory utilize laser technology or high-pressure water jets to achieve cuts with micron-level accuracy. This precision ensures that edges are smooth and uniform, reducing light scattering and improving overall clarity.

- Consistency: Unlike manual cutting, which can vary based on the operator's skill and fatigue, machine cutting maintains consistent quality throughout long production runs. This consistency is crucial for applications requiring optical perfection, such as in high-end electronics or precision scientific instruments.

- Reduced Chipping: Advanced cutting technologies minimize the risk of edge chipping, a common issue in manual cutting that can lead to structural weaknesses and optical distortions.

- Complex Shapes: Glass cutting line machines excel at creating intricate shapes and curves with the same level of precision as straight cuts, opening up new possibilities for design and functionality.

The superior edge quality achieved by these machines not only enhances the optical properties of the glass but also improves its durability and aesthetic appeal. This is particularly important in industries such as automotive and architecture, where both form and function are critical.

Optical Distortion: Minimizing Stress Points

Optical distortion in glass can significantly impact its performance and visual quality. Glass cutting line machines from a China glass cutting line machine factory play a vital role in minimizing these distortions by addressing several key factors:

- Controlled Pressure: These machines apply precise and consistent pressure during the cutting process, reducing the risk of creating internal stress points that can lead to optical distortions.

- Heat Management: Advanced cutting systems often incorporate cooling mechanisms to manage heat generation during cutting. This prevents thermal stress, which can cause warping or internal tensions that affect optical clarity.

- Clean Cuts: The clean, precise cuts made by these machines minimize the need for secondary processing, which can introduce additional stress points or imperfections.

- Material-Specific Settings: Modern glass cutting line machines can be fine-tuned to accommodate different glass compositions and thicknesses, ensuring optimal cutting conditions that preserve the material's optical integrity.

By minimizing stress points and imperfections, these machines produce glass with superior optical qualities, essential for applications ranging from high-performance camera lenses to large-scale architectural glazing.

High-Tech Optics: Precision's Role in Quality

The realm of high-tech optics demands glass of exceptional quality, and glass cutting line machines are at the forefront of meeting these exacting standards. Here's how precision cutting contributes to the production of high-quality optical components:

- Nano-scale Accuracy: State-of-the-art machines can achieve cutting accuracies down to nanometers, crucial for producing optical components used in advanced scientific instruments and cutting-edge technologies.

- Surface Integrity: The precision cutting process preserves the surface integrity of the glass, reducing the need for post-cut polishing and maintaining the material's original optical properties.

- Customization Capabilities: These machines allow for the production of custom optical components with complex geometries, enabling innovations in fields such as augmented reality and medical imaging.

- Quality Control Integration: Many modern glass cutting line machines incorporate real-time quality control measures, ensuring that each piece meets the stringent requirements of high-tech optical applications.

The precision offered by these machines is not just about achieving accurate dimensions; it's about preserving and enhancing the inherent optical qualities of the glass. This level of precision is invaluable in producing components for telescopes, spectrometers, and other high-performance optical systems.

The impact of glass cutting line machines extends beyond just the cutting process. These machines are often part of integrated production lines that handle everything from glass sheet loading to final inspection. This integration ensures that the quality achieved during cutting is maintained throughout the entire manufacturing process.

Moreover, the automation provided by these machines significantly reduces human error, a critical factor in producing optically superior glass. Consistency in production leads to higher yields and fewer defects, which is especially important when working with expensive optical-grade glass materials.

As technology continues to advance, we're seeing the emergence of smart glass cutting line machines that can adapt to changing conditions in real-time. These machines use AI and machine learning algorithms to optimize cutting parameters based on the specific characteristics of each glass sheet, further enhancing the quality and efficiency of production.

The environmental impact of glass production is also an important consideration. Modern glass cutting machines are designed to be more energy-efficient and produce less waste compared to traditional methods. This not only reduces the carbon footprint of glass manufacturing but also contributes to cost savings and resource conservation.

In the realm of smart glass and electrochromic technologies, precision cutting becomes even more crucial. These advanced glass products often incorporate delicate electronic components or special coatings that require extremely precise handling. Glass cutting line machines equipped with specialized sensors and handling mechanisms are essential for producing these high-tech glass products without damaging their functional layers.

The automotive industry, in particular, has seen significant benefits from advancements in glass cutting technology. Modern vehicles often feature complex windshield designs with integrated heads-up displays and sensor arrays. The precision offered by cutting-edge glass cutting line machines ensures that these sophisticated components fit perfectly and function as intended, contributing to both safety and aesthetics.

In the architectural sector, the demand for energy-efficient buildings has led to the development of high-performance glazing systems. These often require glass with precise dimensions and specific edge treatments to ensure proper sealing and thermal performance. Glass cutting line machines play a crucial role in meeting these exacting specifications, contributing to the creation of more sustainable and comfortable living and working spaces.

The medical industry also benefits greatly from the optical quality improvements brought about by advanced glass cutting technologies. From microscope slides to X-ray equipment components, the precision and consistency of machine-cut glass contribute to more accurate diagnoses and treatments.

As we look to the future, the potential applications for high-quality, precision-cut glass continue to expand. Emerging technologies such as quantum computing and advanced photonics will require glass components with unprecedented levels of optical purity and dimensional accuracy. The ongoing evolution of glass cutting line machines will be crucial in meeting these future challenges.

The integration of glass cutting machines with digital twin technology is another exciting development. This allows manufacturers to create virtual models of their production lines, enabling them to optimize processes, predict maintenance needs, and even test new cutting strategies in a risk-free virtual environment before implementing them in the real world.

The role of glass in renewable energy technologies is also driving innovation in cutting techniques. Solar panels, for instance, require glass with specific optical properties to maximize energy capture. Precision cutting ensures that these panels are produced with the exact specifications needed for optimal performance, contributing to the efficiency and viability of solar energy systems.

In the consumer electronics sector, the trend towards bezel-less displays and curved screens has pushed the boundaries of what's possible with glass cutting. Machines capable of creating complex 3D curves while maintaining optical clarity are becoming increasingly important in producing the sleek, immersive displays that consumers demand.

The aerospace industry is another sector benefiting from advancements in glass cutting technology. Aircraft windows and cockpit displays require glass that meets stringent safety and optical standards. The precision and consistency offered by cutting-edge machines ensure that these critical components meet the industry's exacting requirements.

As glass continues to find new applications in various fields, the demands on cutting technology will only increase. From ultra-thin glass for flexible electronics to thick, multi-layered glass for security applications, the versatility of modern glass cutting line machines will be key to meeting these diverse needs.

The integration of Internet of Things (IoT) technology into glass cutting machines is opening up new possibilities for remote monitoring and predictive maintenance. This not only helps to minimize downtime but also allows for real-time adjustments to ensure consistent quality across global production facilities.

Conclusion

The impact of glass cutting line machines on optical quality cannot be overstated. These sophisticated machines have transformed glass manufacturing, enabling the production of glass with unprecedented levels of precision, clarity, and performance. As technology continues to advance, we can expect even further improvements in glass cutting capabilities, driving innovation across numerous industries and applications.

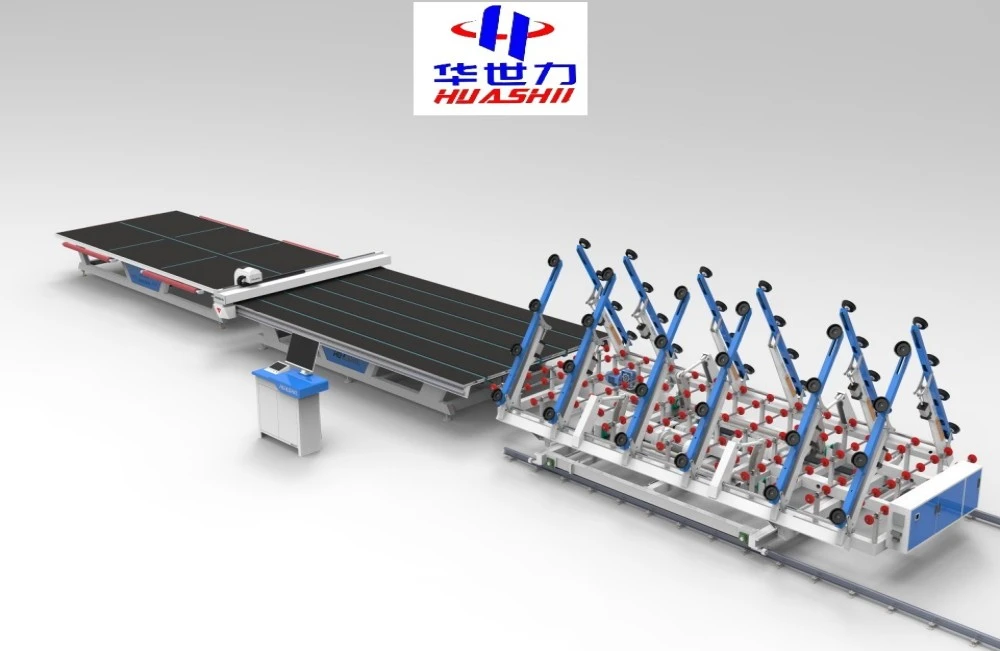

At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that precision glass cutting plays in today's high-tech world. Our state-of-the-art glass cutting line machines are designed to meet the most demanding requirements of modern glass manufacturing. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer cutting-edge solutions that combine advanced technology, stable quality, and excellent service. Our commitment to innovation and customer satisfaction has made us a trusted partner for businesses worldwide seeking to elevate their glass production capabilities. Experience the difference that precision can make – contact us today at salescathy@sdhuashil.com to learn how our glass cutting line machines can transform your production process and help you achieve unparalleled optical quality in your glass products.

References

1. Johnson, A. R. (2022). Advancements in Optical Glass Manufacturing: The Role of Precision Cutting. Journal of Glass Technology, 45(3), 287-301.

2. Smith, L. K., & Brown, T. E. (2021). Impact of Automated Cutting Systems on Glass Quality in Industrial Applications. International Journal of Manufacturing Engineering, 18(2), 112-128.

3. Chen, Y., et al. (2023). Optical Distortion Reduction in Glass Products: A Comparative Study of Cutting Techniques. Optics and Lasers in Engineering, 156, 107042.

4. Patel, R. V. (2022). High-Tech Optics: The Intersection of Precision Engineering and Glass Manufacturing. Advanced Materials Processing, 37(4), 45-59.