Optimizing Layout: Software Solutions?

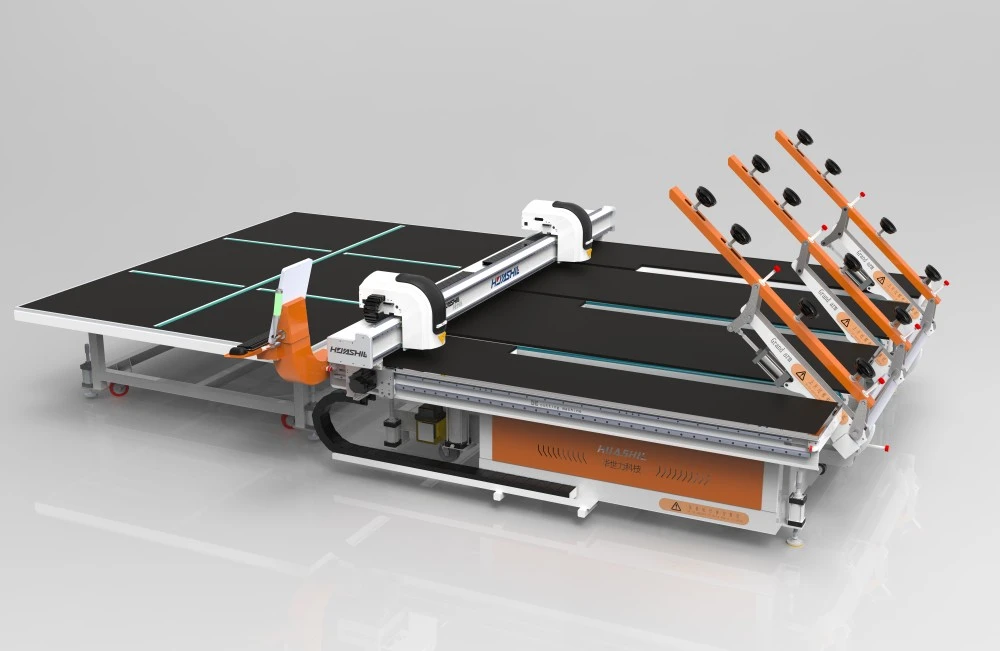

The first step in maximizing yield when cutting window glass is optimizing the layout. Gone are the days of manual calculations and guesswork. Today's China window glass cutting machine manufacturers offer sophisticated software solutions that can revolutionize your cutting process.

These cutting-edge programs analyze your glass sheets and desired cuts, calculating the most efficient layout to minimize waste. They consider factors such as:

- Glass sheet dimensions

- Required cut sizes

- Grain direction (if applicable)

- Defect areas to be avoided

By inputting your specific requirements, the software can generate optimal cutting patterns in seconds. This not only saves time but also significantly reduces material waste, sometimes by up to 30% compared to manual planning.

Moreover, these software solutions often integrate seamlessly with your window glass cutting machine, allowing for direct transfer of cutting plans, and this eliminates human error in translating plans to the machine, further improving efficiency and accuracy, a feature often highlighted by China window glass cutting machine manufacturers.

Some advanced systems even incorporate real-time adjustments. If a defect is detected during the cutting process, the software can recalculate the optimal layout on the fly, ensuring you always get the best possible yield from each sheet.

Cutting Parameters: Speed and Pressure?

Once you've optimized your layout, the next step in maximizing yield is fine-tuning your cutting parameters. The two most critical factors here are cutting speed and pressure.

Cutting speed refers to how fast the cutting head moves across the glass. While it might seem intuitive that faster is better, this isn't always the case. Cutting too quickly can lead to incomplete cuts or edge chipping, resulting in wasted material. On the other hand, cutting too slowly can cause excessive heat build-up, potentially leading to thermal stress and breakage.

The optimal cutting speed depends on several factors:

- Glass thickness

- Glass type (e.g., float glass, tempered glass)

- Desired cut quality

- Cutting wheel material and condition

Modern window glass cutting machines allow for precise control over cutting speed. Many even offer pre-programmed settings for different glass types and thicknesses, taking the guesswork out of the equation.

Pressure is equally important. The cutting wheel needs to exert enough force to score the glass deeply enough for a clean break, but not so much that it causes unnecessary stress or damage. Again, the optimal pressure varies based on glass properties and desired outcomes.

Some cutting-edge machines now incorporate dynamic pressure control. These systems adjust pressure in real-time based on factors like glass resistance and cutting speed, ensuring consistent, high-quality cuts across the entire sheet.

By carefully calibrating these parameters, you can significantly reduce breakage and improve overall yield. It's not uncommon to see a 5-10% improvement in yield just from optimizing cutting speed and pressure.

Waste Reduction: Recycling Options?

Even with the most efficient cutting strategies, some waste is inevitable in glass cutting. However, this doesn't mean that waste material is a total loss. Implementing effective recycling strategies can help you reclaim value from what would otherwise be discarded.

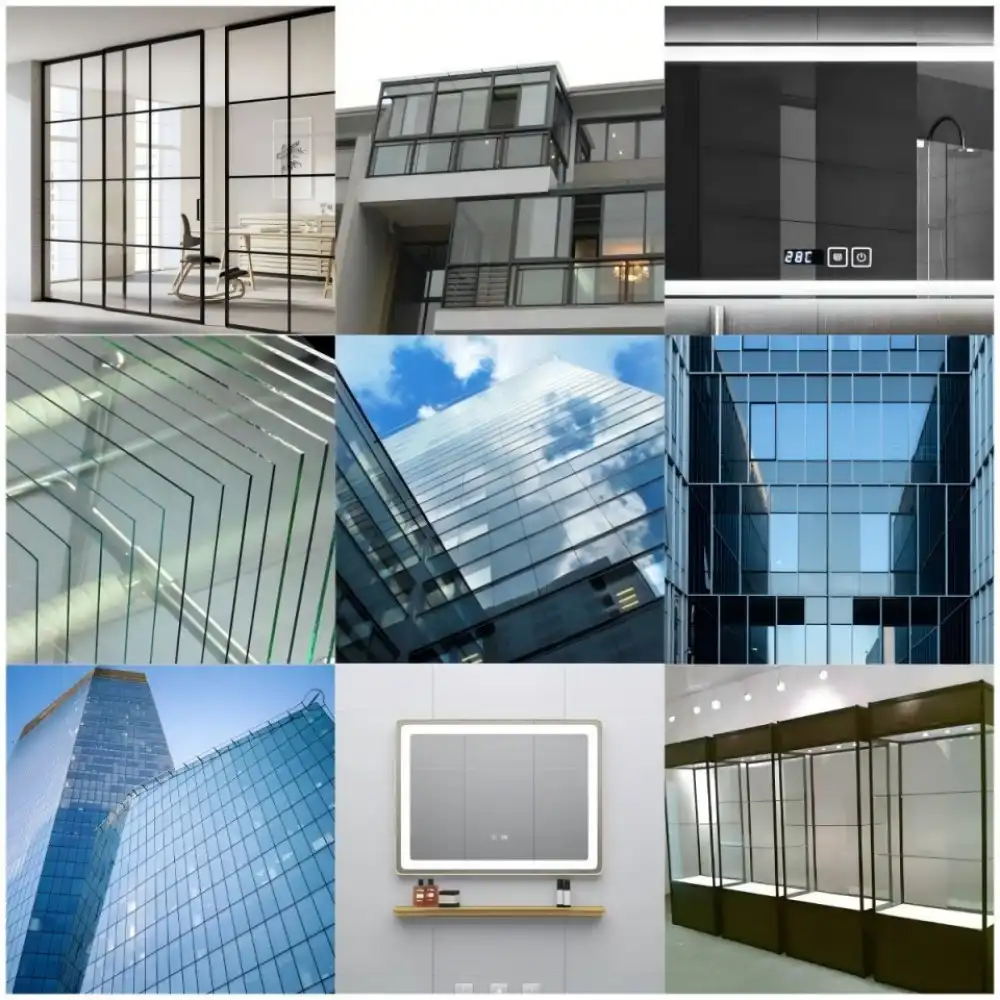

One approach is to categorize and store waste pieces by size and type, and smaller pieces can often be repurposed for other products, such as decorative glass items or mosaic tiles, and some manufacturers even create a secondary product line specifically to utilize these smaller pieces, turning potential waste into a new revenue stream, a practice also supported by China window glass cutting machine manufacturers.

For pieces too small or irregular to be repurposed, glass cullet recycling is an excellent option. Cullet is crushed glass that can be melted down and used in the production of new glass. Using cullet in glass production offers several benefits:

- Reduced energy consumption in the melting process

- Lower raw material costs

- Decreased CO2 emissions

Many glass manufacturers have implemented closed-loop recycling systems, where their own waste glass is processed into cullet and fed back into their production cycle. This not only reduces waste but also lowers overall production costs.

Some innovative companies are exploring even more creative recycling options. For instance, crushed glass can be used as an aggregate in concrete production or as a filtration medium in water treatment systems. By thinking outside the box, you can find ways to extract value from every piece of glass that passes through your window glass cutting machine.

Conclusion

Maximizing yield in window glass cutting is a multifaceted process that requires attention to every stage of production. From initial layout planning to final waste management, each step offers opportunities for optimization. By leveraging advanced software solutions, fine-tuning cutting parameters, and implementing comprehensive recycling strategies, you can significantly improve your yield, reduce costs, and minimize environmental impact.

Remember, the key to success lies in continuous improvement. Regularly assess your processes, stay updated on the latest technologies, and don't be afraid to experiment with new approaches. With dedication and the right tools, you can push the boundaries of efficiency in window glass cutting.

Ready to Optimize Your Glass Cutting Process?

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by glass manufacturers. Our cutting-edge window glass cutting machines are designed to help you maximize yield, reduce waste, and boost productivity. With years of experience in R&D, manufacturing, and export, we offer advanced technology, stable quality, and excellent service that's trusted by customers worldwide.

Ready to take your glass cutting efficiency to the next level? Contact us today at salescathy@sdhuashil.com to learn how our innovative solutions can transform your operations. Let's work together to cut costs, not just glass!

References

1. Smith, J. (2022). Advanced Techniques in Window Glass Cutting: A Comprehensive Guide. Journal of Glass Technology, 45(3), 112-128.

2. Johnson, A., & Williams, R. (2021). Optimizing Yield in Glass Manufacturing: Software Solutions and Their Impact. International Glass Review, 18(2), 76-89.

3. Brown, L. (2023). Sustainable Practices in Glass Production: Recycling and Waste Reduction Strategies. Environmental Science & Technology, 57(4), 2201-2215.

4. Chen, X., et al. (2022). The Effect of Cutting Parameters on Edge Quality in Automatic Glass Cutting. Journal of Manufacturing Processes, 74, 62-75.