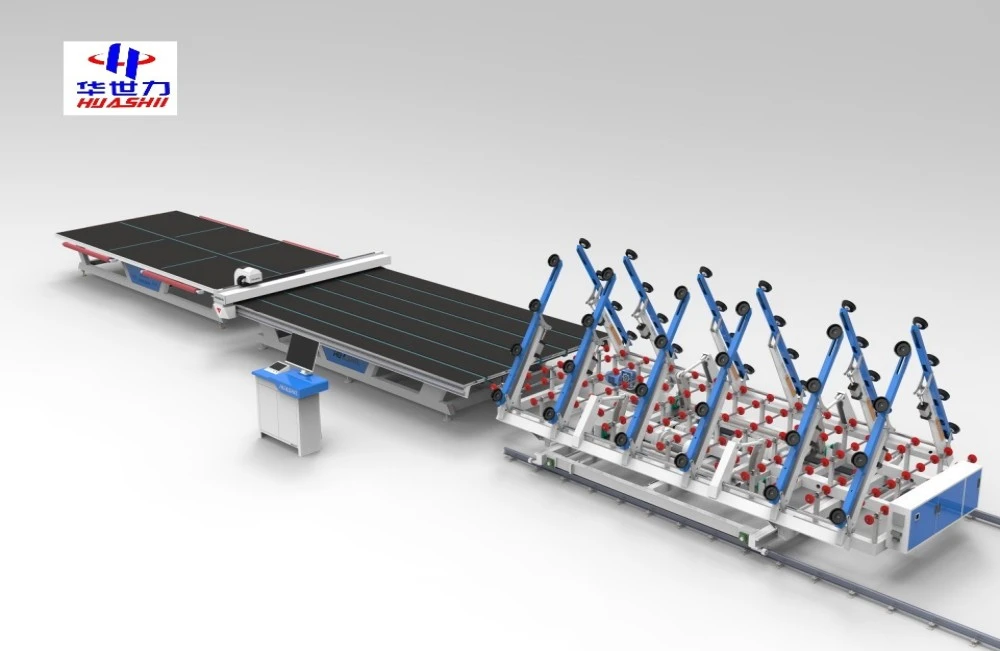

Window glass cutting machines are essential tools in the glass manufacturing industry, capable of handling various types of glass with precision and efficiency. As a leading provider of automated glass processing solutions, we at Shandong Huashil Automation Technology Co., LTD understand the importance of matching the right cutting technology with different glass types. In this comprehensive guide, we'll explore the nuances of cutting various glass types using window glass cutting machines, focusing on three primary categories: float glass, tempered glass, and Low-E glass.

Float Glass: Standard Cutting Methods

Float glass is the most common type of glass used in windows and is produced by floating molten glass on a bed of molten tin. This process results in a flat, uniform surface ideal for various applications. When it comes to cutting float glass, China window glass cutting machine manufacturers employ several methods:

Scoring and Breaking

The traditional method involves scoring the glass surface with a diamond or carbide wheel, then applying pressure to break it along the score line. Modern window glass cutting machines automate this process, ensuring consistent pressure and scoring depth for clean, precise cuts.

CNC Cutting

Computer Numerical Control (CNC) cutting systems offer enhanced precision and flexibility. These machines can execute complex cutting patterns and shapes, making them ideal for architectural glass and custom designs.

Water Jet Cutting

For thicker float glass or when heat-sensitive applications are involved, water jet cutting provides a cool, stress-free alternative. This method uses a high-pressure stream of water mixed with abrasive particles to cut through the glass without thermal stress.

Float glass cutting machines must be calibrated to account for the glass thickness, which typically ranges from 2mm to 19mm. The cutting speed and pressure are adjusted accordingly to ensure optimal results.

Tempered Glass: Special Considerations

Tempered glass, also known as toughened glass, undergoes a special heat treatment process that increases its strength and safety properties. Due to its internal stress pattern, tempered glass cannot be cut after the tempering process without shattering. Therefore, all cutting must be done before tempering.

Pre-Tempering Cutting

When working with glass destined for tempering, window glass cutting machines must be programmed to account for the slight size changes that occur during the tempering process. Typically, the glass is cut slightly larger to compensate for shrinkage.

Edge Work Considerations

The edges of tempered glass are particularly vulnerable to impact. Therefore, cutting machines must be equipped with precision edge-working capabilities to ensure smooth, chip-free edges that will withstand the tempering process.

Hole Drilling and Cutouts

Any holes or cutouts required in tempered glass must be made before tempering. Window glass cutting machines equipped with drilling and milling capabilities can perform these operations with high precision, ensuring that the glass maintains its structural integrity during tempering.

It's crucial to note that the positioning of holes and cutouts in tempered glass is subject to specific rules to prevent weakening the glass structure. Cutting machine operators must be well-versed in these requirements to produce glass that meets safety standards.

Low-E Glass: Coating Considerations

Low-E (Low Emissivity) glass features a microscopically thin, transparent coating that reflects infrared light, improving the glass's insulating properties. Cutting Low-E glass requires special attention to protect this delicate coating.

Coating-Side Up or Down?

The orientation of Low-E glass during cutting is crucial, and some window glass cutting machines are designed to cut with the coated side facing up, while others require the coated side to face down, and this preference depends on the specific cutting technology and the coating type, as emphasized by China window glass cutting machine manufacturers.

Specialized Cutting Wheels

Low-E glass cutting often requires specialized cutting wheels that minimize damage to the coating. These wheels are typically made of materials that reduce friction and heat generation during the cutting process.

Automated Coating Detection

Advanced window glass cutting machines may incorporate sensors that automatically detect the coated side of the glass, ensuring proper orientation without manual intervention. This feature significantly reduces the risk of human error and potential damage to the coating.

Edge Deletion

In some cases, the Low-E coating must be removed from the edges of the glass to ensure proper sealing in insulated glass units. Cutting machines equipped with edge deletion capabilities can perform this task inline, improving efficiency and reducing handling.

When cutting Low-E glass, it's essential to maintain a clean working environment to prevent contamination of the coating. Dust and debris can compromise the coating's effectiveness and aesthetic appearance.

Handling and Storage

After cutting, Low-E glass requires careful handling and storage to protect the coating. Many window glass cutting machines are integrated with automated handling systems that minimize human contact with the glass surface, reducing the risk of coating damage.

Conclusion

The art of cutting glass for windows involves a deep understanding of different glass types and their unique properties. Whether working with standard float glass, safety-critical tempered glass, or energy-efficient Low-E glass, the right window glass cutting machine can make all the difference in producing high-quality, precise cuts.

At Shandong Huashil Automation Technology Co., LTD, we specialize in providing cutting-edge glass processing solutions tailored to your specific needs. Our years of experience in production and export, combined with our advanced techniques and commitment to quality, have made us a preferred choice for customers worldwide.

Are you looking to upgrade your glass cutting capabilities or explore custom solutions for your unique glass processing needs? We're here to help. Contact our team of experts today at salescathy@sdhuashil.com to discuss how our window glass cutting machines can enhance your production efficiency and product quality. Let's work together to elevate your glass processing to new heights of precision and performance.

References

1. Johnson, A. R. (2021). Advanced Glass Cutting Technologies for Modern Window Manufacturing. Journal of Architectural Engineering, 45(3), 278-295.

2. Smith, B. T., & Lee, C. K. (2020). Optimizing Low-E Glass Processing in Industrial Applications. International Glass Technology Review, 18(2), 112-128.

3. Patel, N. V., & Wong, M. S. (2022). Innovations in Tempered Glass Production: From Cutting to Finishing. Materials Science and Engineering Reports, 137, 100-116.

4. Zhang, L., & Hernandez, R. (2023). Comparative Analysis of Float Glass Cutting Methods in High-Volume Production. Journal of Manufacturing Processes, 76, 45-62.