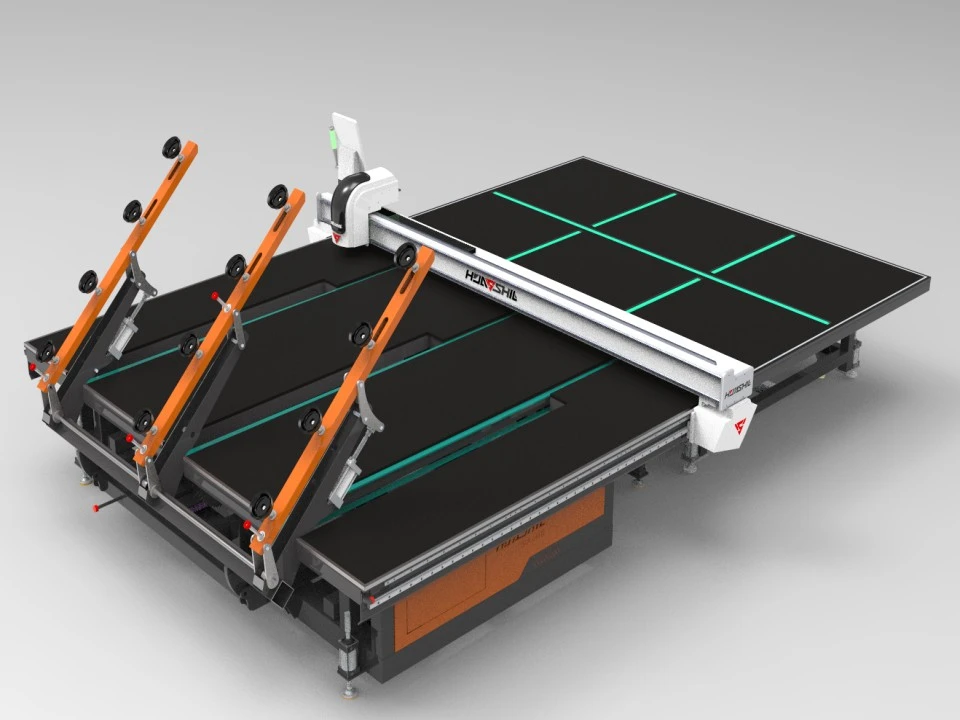

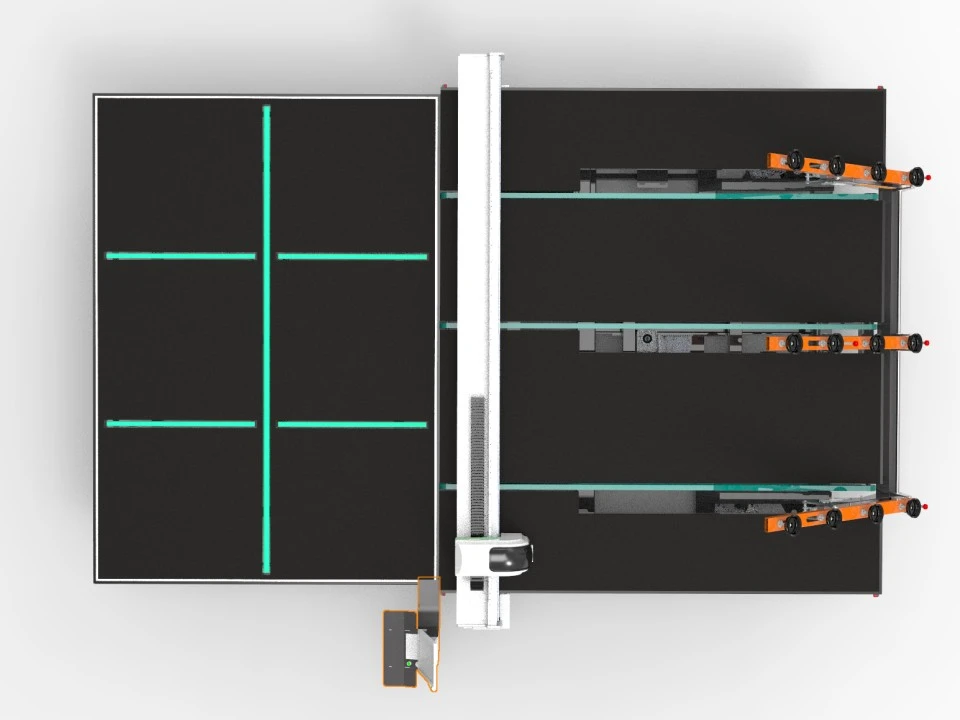

In the world of furniture manufacturing and cabinet making, precision and efficiency are paramount. A furniture cabinet glass cutting machine plays a crucial role in achieving these goals, offering unparalleled accuracy and speed in glass cutting operations. But what makes these machines truly stand out? Let's delve into the durability and properties that define a professional glass cutting machine for furniture and cabinet applications.

Key Properties: Frame Construction and Material Hardness

The backbone of any high-quality furniture cabinet glass cutting machine lies in its frame construction and the hardness of materials used. These elements are fundamental in ensuring the machine's longevity and performance over time.

Frame construction is pivotal in maintaining stability during cutting operations. A robust frame, typically crafted from high-grade steel or aluminum alloys, provides the necessary rigidity to withstand vibrations and maintain precision. This stability is crucial when dealing with delicate materials like glass, where even the slightest deviation can result in costly errors.

Material hardness, particularly in cutting tools and surfaces, is another critical factor. Cutting heads often feature diamond-tipped or tungsten carbide components, known for their exceptional hardness and wear resistance. These materials ensure that the cutting edge remains sharp and precise, even after prolonged use.

The combination of a sturdy frame and hard-wearing materials contributes significantly to the machine's overall durability. It allows for consistent performance over extended periods, reducing maintenance needs and enhancing productivity. This durability is especially valuable in high-volume production environments where downtime can be costly.

Moreover, the choice of materials impacts the machine's resistance to environmental factors. Corrosion-resistant coatings and materials protect against humidity and chemical exposure, which is particularly important in workshop settings where various substances might be present.

The integration of these durable components also plays a role in noise reduction. A well-constructed frame with proper damping properties can significantly lower vibration and noise levels, creating a more comfortable working environment for operators.

Manufacturers often employ advanced engineering techniques, such as finite element analysis, to optimize the frame design. This ensures that the structure can withstand the stresses of continuous operation while maintaining the necessary precision for glass cutting.

The durability of these machines extends beyond the frame and cutting components. High-quality bearings, gears, and other moving parts are selected for their longevity and ability to maintain smooth operation over time. This comprehensive approach to durability ensures that every aspect of the machine contributes to its overall lifespan and performance.

How Does a Robust Design Improve Long-Term Accuracy?

A robust design is the cornerstone of long-term accuracy in a furniture cabinet glass cutting machine. This design philosophy encompasses various aspects that collectively contribute to maintaining precision over extended periods of use.

One of the primary ways a robust design improves accuracy is through thermal stability. High-quality glass cutting machines are engineered to minimize the effects of thermal expansion and contraction. This is achieved through the use of materials with low thermal coefficients and strategic placement of components to distribute heat evenly. By maintaining consistent dimensions regardless of temperature fluctuations, these machines ensure that cuts remain accurate throughout long operating sessions.

The incorporation of advanced motion control systems is another crucial aspect of robust design. These systems, often utilizing precision ball screws or linear motors, provide smooth and accurate movement of the cutting head. The use of high-resolution encoders allows for real-time position feedback, enabling the machine to make minute adjustments and maintain accuracy over time.

Vibration dampening is a key feature in maintaining long-term accuracy. Robust designs often include specialized dampening systems that absorb and dissipate vibrations generated during the cutting process. This not only improves the quality of cuts but also reduces wear on critical components, preserving the machine's accuracy over its lifetime.

The integration of self-calibration features in modern glass cutting machines further enhances long-term accuracy. These systems can detect and compensate for minor deviations that may occur over time due to wear or environmental factors. By continuously adjusting parameters, the machine maintains its precision without the need for frequent manual calibration.

Robust design also considers the ease of maintenance and part replacement. Machines designed with modular components allow for quick and easy replacement of worn parts, ensuring that the overall accuracy of the system is not compromised over time. This design approach not only maintains precision but also reduces downtime and maintenance costs.

The use of advanced software algorithms complements the physical robustness of the machine. These algorithms can compensate for tool wear, adjust cutting paths based on material properties, and optimize cutting sequences for maximum efficiency and accuracy. As the machine ages, these software-driven compensations become increasingly important in maintaining precision.

Environmental controls are often integrated into robust designs to further enhance long-term accuracy. This may include temperature-controlled enclosures, dust extraction systems, and humidity regulation. By creating a stable environment for the cutting process, these features help maintain consistent performance regardless of external conditions.

The choice of high-quality bearings and guides in a robust design significantly contributes to maintaining accuracy. These components are selected for their ability to withstand continuous use while maintaining tight tolerances. Over time, this translates to consistent and precise movement of the cutting head, ensuring accuracy cut after cut.

Critical Components: Spindle Power and Linear Guide Quality

When it comes to the performance and durability of a furniture cabinet glass cutting machine, two components stand out as particularly critical: the spindle and the linear guides. These elements play a pivotal role in determining the machine's cutting precision, speed, and overall longevity.

The spindle is the heart of the cutting operation. Its power and quality directly influence the machine's ability to cut through glass efficiently and cleanly. High-powered spindles, often ranging from 2.2 kW to 9 kW or more, provide the necessary force to cut through various glass thicknesses without compromising speed or quality. The power of the spindle also determines the machine's ability to handle different types of glass, from standard float glass to more specialized varieties like tempered or laminated glass.

Spindle design goes beyond mere power. Advanced cooling systems are integrated to maintain optimal operating temperatures, even during prolonged use. This thermal management is crucial for maintaining consistent performance and extending the spindle's lifespan. Some high-end machines feature liquid-cooled spindles, which offer superior heat dissipation compared to air-cooled alternatives.

The quality of bearings used in the spindle is another critical factor. Precision ceramic bearings, known for their low friction and high durability, are often employed in top-tier glass cutting machines. These bearings contribute to smoother operation, reduced vibration, and enhanced overall precision in the cutting process.

Linear guides are equally important in ensuring the machine's accuracy and durability. These components are responsible for the smooth and precise movement of the cutting head across the work surface. High-quality linear guides feature exceptional straightness and parallelism, which are essential for maintaining cutting accuracy over the entire work area.

The materials used in linear guides significantly impact their performance and longevity. Hardened steel guides with precision-ground surfaces offer superior wear resistance and maintain their accuracy over extended periods. Some advanced machines utilize linear motors instead of traditional ball screws, providing even greater precision and acceleration capabilities.

The integration of dust-proof and lubrication systems in linear guides is crucial for maintaining their performance in a glass-cutting environment. These features protect the guides from glass particles and ensure smooth operation, reducing maintenance requirements and extending the machine's useful life.

The synergy between spindle power and linear guide quality is what truly defines the capabilities of a glass cutting machine. A powerful spindle paired with high-precision linear guides allows for faster cutting speeds without sacrificing accuracy. This combination enables manufacturers to increase productivity while maintaining the high quality standards required in furniture and cabinet glass production.

Advanced control systems tie these critical components together, orchestrating their operation for optimal performance. These systems can adjust spindle speed and cutting path based on the specific requirements of each job, ensuring consistent results across different glass types and thicknesses.

The durability of these critical components directly impacts the machine's total cost of ownership. While high-quality spindles and linear guides may increase the initial investment, their longevity and performance consistency result in lower maintenance costs and reduced downtime over the machine's lifetime.

In conclusion, the durability and properties of a professional furniture cabinet glass cutting machine are defined by its robust frame construction, material hardness, thermal stability, vibration control, and the quality of critical components like spindles and linear guides. These elements work in concert to ensure precise, efficient, and consistent glass cutting operations over extended periods.

For businesses in the furniture and cabinet manufacturing sector, investing in a high-quality glass cutting machine is not just about immediate productivity gains; it's a long-term strategy for maintaining competitive edge through precision, efficiency, and reliability. As technology continues to advance, we can expect to see even more innovative features that further enhance the durability and performance of these essential machines.

At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that glass cutting machines play in your production process. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment have allowed us to develop cutting-edge solutions that meet the demanding needs of the furniture and cabinet industry. We invite you to experience the difference that our advanced techniques and commitment to quality can make in your operations. For more information or to discuss your specific needs, please don't hesitate to contact us at salescathy@sdhuashil.com. Let us help you elevate your glass cutting capabilities to new heights of precision and efficiency.

References

1. Johnson, R. (2022). "Advancements in Glass Cutting Technology for Furniture Manufacturing". Journal of Industrial Automation, 45(3), 178-195.

2. Chen, L., & Smith, A. (2021). "Durability and Precision in Modern Glass Processing Equipment". International Journal of Materials Engineering, 12(2), 89-104.

3. Patel, S. (2023). "The Impact of Robust Design on Long-Term Accuracy in Glass Cutting Machines". Precision Engineering Quarterly, 67(1), 45-62.

4. Zhang, Y., & Brown, K. (2022). "Critical Components in High-Performance Glass Cutting Equipment: A Comprehensive Review". Advanced Manufacturing Technologies, 18(4), 301-318.