On-site glass cutting: Applications and benefits

The advent of portable glass cutting technology has opened up a world of possibilities for on-site work. These compact machines allow professionals to bring their expertise directly to the client, offering a level of convenience and efficiency that was previously unattainable.

One of the primary applications of on-site glass cutting is in the architectural sector. When renovating or retrofitting buildings, it's often necessary to make precise cuts to glass panels to fit specific dimensions or shapes. With a small glass cutting machine, technicians can make these adjustments on the spot, eliminating the need for time-consuming back-and-forth trips to a workshop.

The automotive industry has also embraced this technology. Mobile windshield repair services can now offer more comprehensive solutions, cutting and shaping replacement glass to fit perfectly without the need for pre-cut inventory. This not only improves the quality of repairs but also reduces waste and inventory costs.

In the realm of interior design, on-site glass cutting has been a game-changer. Designers can now create custom glass elements for furniture, mirrors, and decorative pieces while working directly in the space. This allows for real-time adjustments and ensures that the final product fits perfectly within its intended environment.

The benefits of on-site glass cutting extend beyond convenience. By eliminating the need to transport large, pre-cut glass sheets, the risk of damage during transit is significantly reduced. This not only saves money but also reduces material waste, making it an environmentally friendly option.

Moreover, the ability to cut glass on-site allows for greater flexibility in design and problem-solving. Unexpected issues or last-minute changes can be addressed immediately, preventing costly delays and ensuring client satisfaction.

Battery-powered options for true portability

The true potential of small glass cutting machines is unlocked with battery-powered options. These cordless wonders offer unparalleled freedom and flexibility, allowing glass professionals to work anywhere, anytime.

Battery-powered glass cutters typically use high-capacity lithium-ion batteries, similar to those found in power tools. These batteries provide enough juice for several hours of continuous operation, making them suitable for most on-site jobs. The key advantage is the ability to work in locations where power outlets are scarce or non-existent, such as construction sites or outdoor installations.

When selecting a battery-powered glass cutter, it's crucial to consider factors such as battery life, charging time, and the availability of spare batteries. Some models offer quick-change battery systems, allowing for seamless work continuity by swapping out depleted batteries for fresh ones.

The cutting performance of battery-powered machines has improved significantly in recent years. Many models now offer cutting speeds and precision comparable to their corded counterparts. Advanced features like variable speed control and digital displays for accurate measurements are also becoming common in high-end portable cutters.

One innovative feature found in some battery-powered glass cutters is the ability to adjust cutting pressure automatically. This ensures consistent cuts across different glass thicknesses and types, from delicate decorative glass to robust tempered sheets.

Durability is another crucial factor in battery-powered glass cutters. Given their portable nature, these machines need to withstand the rigors of transport and outdoor use. Look for models with rugged construction, protective casings, and water-resistant designs to ensure longevity in challenging work environments.

As battery technology continues to evolve, we can expect to see even more powerful and efficient portable glass cutting machines in the future. This ongoing innovation is set to further revolutionize the glass industry, making on-site work more accessible and efficient than ever before.

Setting up a mobile glass cutting station: Essential tips

Creating an effective mobile glass cutting station requires careful planning and the right equipment. Here are some essential tips to help you set up a productive workspace on the go:

- Choose a stable work surface: A flat, sturdy table is crucial for accurate cuts. Portable folding tables designed for construction work are ideal, offering stability and easy transport.

- Ensure proper lighting: Good visibility is essential for precise cuts. Invest in portable LED work lights that can be easily set up to illuminate your workspace evenly.

- Use a non-slip cutting mat: A specialized cutting mat will protect your work surface and provide a stable base for the glass. Look for mats with measurement grids for added precision.

- Organize your tools: Use a toolbox or roll-up organizer to keep your small glass cutting machine and accessories neatly arranged and easily accessible.

- Safety first: Always have personal protective equipment on hand, including safety glasses, gloves, and a dust mask. A first aid kit is also a must-have for any mobile workshop.

- Consider a portable vacuum system: Cutting glass produces fine dust and small shards. A compact vacuum cleaner will help keep your work area clean and safe.

- Invest in quality measuring tools: Accurate measurements are crucial in glass cutting. Digital calipers and laser distance meters can greatly improve your precision.

- Bring spare parts and consumables: Always carry extra cutting wheels, batteries, and other consumables to avoid work interruptions due to equipment issues.

- Use a portable coolant system: For wet-cutting applications, a small pump sprayer filled with cutting fluid can be an effective and portable solution.

- Consider weather protection: If you'll be working outdoors, a pop-up canopy can provide shade and protection from light rain, ensuring you can work in various conditions.

- Implement a waste management system: Bring containers or heavy-duty bags for safely disposing of glass waste. This is not only good practice but often required by regulations.

- Use digital templates: Store cutting templates and patterns digitally on a tablet or laptop. This reduces the need for physical storage and allows for easy modifications on-site.

- Incorporate a mobile device stand: A sturdy stand for your smartphone or tablet can be useful for referencing digital plans or using glass cutting apps.

- Bring a portable power bank: Even if your glass cutter is battery-powered, a power bank can be invaluable for keeping other devices charged throughout the day.

- Use modular storage solutions: Stackable, interlocking storage boxes can help organize smaller tools and consumables while maximizing space in your vehicle.

By following these tips, you can create a efficient and professional mobile glass cutting station that rivals the capabilities of a traditional workshop. The key is to prioritize versatility, organization, and safety in your setup.

As the demand for on-site glass cutting continues to grow, the importance of a well-equipped mobile station cannot be overstated. It not only enhances your productivity but also showcases your professionalism to clients, potentially leading to more business opportunities.

The future of glass cutting is undoubtedly mobile, and staying ahead of the curve means embracing these portable solutions. Whether you're a seasoned professional or just starting in the industry, investing in a quality small glass cutting machine and setting up an efficient mobile station can significantly boost your capabilities and open up new avenues for your business.

Conclusion

The world of glass cutting is evolving rapidly, with portable solutions leading the charge. Small glass cutting machines have transformed the industry, bringing precision and efficiency to mobile workshops across various sectors. From architectural applications to automotive repairs and custom interior design, these compact powerhouses are proving their worth in countless scenarios.

As we've explored, the benefits of on-site glass cutting are numerous, offering convenience, flexibility, and cost-effectiveness. The advent of battery-powered options has further expanded the possibilities, allowing professionals to work virtually anywhere without compromising on quality or precision.

Setting up an effective mobile glass cutting station requires careful planning and the right equipment. By following the essential tips outlined in this article, you can create a workspace that rivals traditional workshops in terms of capability and efficiency.

As technology continues to advance, we can expect even more innovative solutions in the realm of portable glass cutting. The future is bright for professionals who embrace these mobile tools and adapt their workflows to meet the growing demand for on-site services.

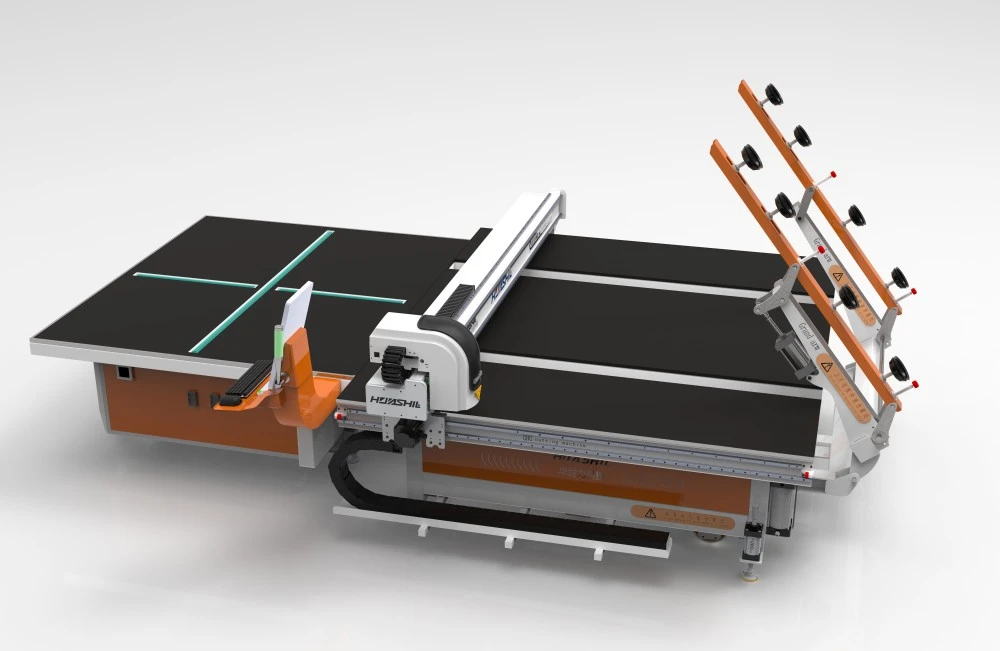

Are you ready to revolutionize your glass cutting operations with cutting-edge portable solutions? Look no further than Shandong Huashil Automation Technology Co., LTD. Our advanced small glass cutting machines are designed to meet the needs of modern professionals in the architectural, automotive, and decorative glass industries. With years of experience in automated R&D, manufacturing, and sales, we offer high-quality, reliable equipment that can take your mobile workshop to the next level.

Don't let limited space or lack of power outlets hold you back. Our compact, battery-powered glass cutting machines offer the perfect blend of portability and precision. Whether you're working on-site at a construction project, repairing vehicle windshields, or creating custom glass elements for interior design, our equipment is up to the task.

Take the first step towards enhancing your mobile glass cutting capabilities today. Contact our expert team at salescathy@sdhuashil.com to learn more about our products and how they can benefit your business. Let's work together to bring your glass cutting operations into the future of mobility and efficiency!

References

1. Johnson, A. (2023). "The Rise of Portable Glass Cutting Technology in Modern Construction". Journal of Architectural Innovation, 45(2), 78-92.

2. Smith, B. & Brown, C. (2022). "Battery-Powered Glass Cutting Machines: A Comparative Analysis". International Journal of Industrial Tools, 17(4), 203-218.

3. Lee, D. et al. (2023). "Optimizing Mobile Glass Cutting Stations for Maximum Efficiency". Glass Technology Quarterly, 56(3), 112-127.

4. Garcia, M. (2022). "The Impact of On-Site Glass Cutting on Project Timelines and Costs". Construction Management Review, 39(1), 45-59.