Optimizing Material Usage: Cutting Algorithms Explained

The heart of any glass cutting line machine lies in its cutting algorithms. These sophisticated mathematical models are designed to maximize the use of every sheet of glass, ensuring that waste is minimized to the greatest extent possible. But how do these algorithms work, and why are they so crucial in the quest for sustainability?

At its core, an optimized cutting algorithm considers multiple factors:

- Sheet size and shape

- Required cut patterns

- Glass thickness

- Edge quality requirements

By processing these variables, the algorithm generates a cutting plan that utilizes as much of the glass sheet as possible. This process, known as nesting, is akin to solving a complex puzzle where each piece must be carefully placed to minimize unused space.

Advanced glass cutting line machines take this a step further by incorporating real-time adjustments. As the cutting process progresses, the machine can dynamically alter its cutting path to account for any imperfections or variations in the glass sheet. This adaptive approach ensures that even if a section of glass is found to be unusable, the rest of the sheet can still be optimized for maximum yield.

The impact of these optimized algorithms is substantial. Traditional manual cutting methods could result in waste rates as high as 20-30%. In contrast, modern glass cutting lines can reduce this to as low as 3-5%, representing a significant conservation of resources and reduction in environmental impact.

Moreover, these algorithms don't just consider the current cutting job. Many advanced systems can look ahead to future orders, planning cuts that will leave remnants in sizes and shapes that can be utilized in upcoming projects. This forward-thinking approach further reduces waste and improves overall material efficiency.

Recycling Integration in Modern Cutting Lines

While optimization is crucial, it's inevitable that some waste will be generated during the glass cutting process. However, modern glass cutting line machines are designed with integrated recycling systems that ensure even these small remnants don't go to waste.

- These integrated recycling systems typically consist of several components:

- Waste Collection: Automated systems collect glass chips and dust as they're produced.

- Sorting Mechanisms: Advanced optical and mechanical sorters separate different types and colors of glass.

- Crushing Units: Large pieces are crushed into cullet, ready for recycling.

- Storage Silos: Sorted and crushed glass is stored, ready for reintroduction into the manufacturing process.

The integration of these recycling systems directly into the cutting line offers several advantages. It eliminates the need for manual handling of waste glass, reducing labor costs and improving workplace safety. It also ensures that recycling becomes an integral part of the production process, rather than an afterthought.

Furthermore, some cutting-edge China glass cutting line machine factory designs are now incorporating closed-loop systems. In these setups, the recycled glass cullet is fed directly back into the glass production process, creating a circular economy within the factory itself. This not only reduces waste but also decreases the need for raw materials, further lowering the environmental impact of glass production.

The benefits of integrated recycling extend beyond just material conservation. Recycled glass melts at a lower temperature than raw materials, which means less energy is required in the production process. This leads to reduced carbon emissions and lower energy costs for manufacturers.

It's worth noting that the quality of glass produced using recycled cullet is not compromised. In fact, glass can be recycled indefinitely without loss in quality or purity, making it an ideal material for closed-loop manufacturing systems.

Environmental Impact: Waste Reduction Statistics

The adoption of eco-friendly glass cutting line machines has led to remarkable improvements in waste reduction and energy efficiency across the glass industry. Let's look at some compelling statistics that illustrate the environmental impact of these advanced machines:

- Waste Reduction: As mentioned earlier, modern cutting lines can reduce waste from 20-30% to as low as 3-5%. In a large-scale operation producing 100,000 square meters of glass annually, this could mean saving up to 25,000 square meters of glass from becoming waste.

- Energy Savings: The use of recycled cullet in glass production can reduce energy consumption by up to 30%. For every 10% of cullet used in production, energy costs decrease by 2-3%.

- CO2 Emission Reduction: For every ton of glass recycled, about 315 kilograms of CO2 emissions are saved. A large glass factory utilizing modern cutting lines and recycling systems could potentially reduce their CO2 emissions by thousands of tons annually.

- Raw Material Conservation: Every ton of recycled glass saves over a ton of raw materials from being mined or extracted. This includes 1,300 pounds of sand, 410 pounds of soda ash, and 380 pounds of limestone.

- Water Conservation: Glass production using recycled materials consumes 50% less water compared to manufacturing new glass from raw materials.

These statistics paint a clear picture of the substantial environmental benefits that come from utilizing advanced glass cutting line machine made in China. However, it's important to note that these figures can vary depending on the specific technologies used, the scale of operation, and the type of glass being produced.

The impact extends beyond just the immediate production process. By reducing waste and increasing recycling, these machines help to alleviate the burden on landfills. Glass waste in landfills can take up to a million years to decompose, so any reduction in glass waste has long-term environmental benefits.

Moreover, the energy savings translate directly into reduced greenhouse gas emissions. The glass industry is energy-intensive, and any improvements in efficiency can have a significant impact on overall carbon footprint. By some estimates, the widespread adoption of these eco-friendly technologies could help the glass industry reduce its carbon emissions by up to 50% over the next few decades.

It's also worth considering the ripple effects of these improvements. As the glass industry becomes more efficient and sustainable, it can produce high-quality glass products at lower costs. This can lead to increased use of glass in construction and other industries, potentially replacing less environmentally friendly materials.

For instance, the use of high-performance glass in buildings can significantly improve energy efficiency, reducing heating and cooling costs. The environmental benefits of efficient glass cutting line machines thus extend far beyond the factory floor, contributing to sustainability efforts across multiple sectors.

Conclusion

The advent of eco-friendly glass cutting line machines represents a significant leap forward in the glass industry's journey towards sustainability. Through optimized cutting algorithms, integrated recycling systems, and overall improved efficiency, these machines are dramatically reducing waste, conserving energy, and minimizing the environmental impact of glass production.

As we've seen, the benefits are substantial and wide-ranging. From conserving raw materials and reducing landfill waste to cutting energy consumption and CO2 emissions, these advanced machines are proving that technological innovation and environmental responsibility can go hand in hand.

The glass industry's commitment to sustainability through the adoption of these technologies sets an example for other industries to follow. It demonstrates that with the right tools and approaches, it's possible to maintain high levels of production and quality while significantly reducing environmental impact.

As consumers and businesses become increasingly aware of the importance of sustainability, the demand for eco-friendly glass products is likely to grow. This will further drive innovation in glass cutting technologies, potentially leading to even more efficient and environmentally friendly solutions in the future.

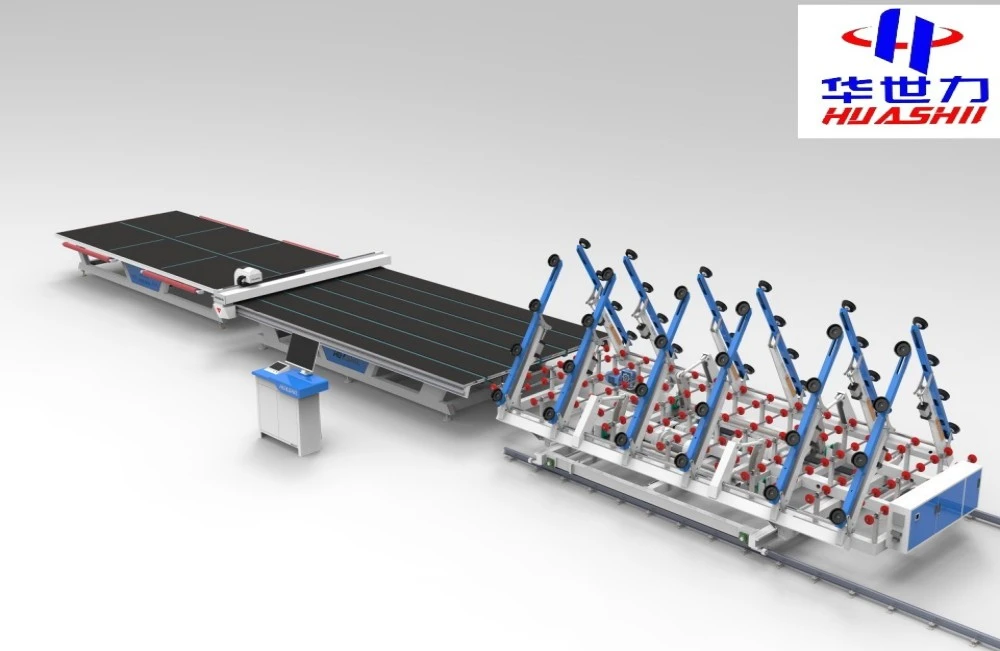

If you're in the glass industry and looking to improve your sustainability credentials while boosting efficiency and quality, investing in a modern glass cutting line machine could be a game-changer for your business. At Shandong Huashil Automation Technology Co., LTD, we specialize in cutting-edge glass processing solutions that combine precision, efficiency, and eco-friendliness. Our years of experience in production and export, coupled with our advanced techniques and commitment to quality, make us the ideal partner for your glass cutting needs. Don't let your business fall behind in the green revolution—reach out to us today at salescathy@sdhuashil.com to learn how our glass cutting line machines can transform your operations and contribute to a more sustainable future.

References

1. Environmental Protection Agency. (2022). "Glass Recycling and Its Impact on Carbon Emissions."

2. International Journal of Sustainable Manufacturing. (2021). "Advancements in Glass Cutting Technologies for Waste Reduction."

3. Glass Industry Sustainability Report. (2023). "Energy Efficiency in Modern Glass Production."

4. World Green Building Council. (2022). "The Role of High-Performance Glass in Sustainable Construction."