Understanding Cullet: The Recyclable Glass Gold

Cullet, the industry term for recycled glass, is rapidly becoming the gold standard in glass manufacturing. Unlike many other materials, glass can be recycled indefinitely without losing its quality or purity. This unique property makes cullet an invaluable resource in the production of new glass products.

The process of creating cullet begins with the collection of waste glass from various sources - be it discarded bottles, broken windows, or industrial glass waste. This collected glass is then processed through an automatic glass breaking machine, which efficiently breaks down the glass into smaller, uniform pieces suitable for recycling.

The benefits of using cullet in glass production are manifold:

- Energy Efficiency: Melting cullet requires significantly less energy compared to melting raw materials, leading to reduced energy consumption in glass production.

- Reduced Carbon Footprint: The use of cullet in glass manufacturing results in lower CO2 emissions, contributing to a greener production process.

- Conservation of Natural Resources: By recycling glass, we reduce the need for raw materials like sand, soda ash, and limestone, preserving our natural resources.

- Waste Reduction: Cullet production diverts glass waste from landfills, addressing the growing concern of waste management.

The industrial glass breaking equipment plays a crucial role in this process. These machines are designed to handle large volumes of glass waste, breaking them down into cullet of various sizes as per the requirements of different glass manufacturing processes.

Quality Control: Ensuring High-Grade Cullet Output

While the concept of recycling glass sounds straightforward, the reality is far more complex. Not all glass is created equal, and the quality of cullet can significantly impact the final glass product. This is where advanced automatic glass breaking machines come into play, offering sophisticated quality control measures to ensure high-grade cullet output.

Modern glass breaking equipment incorporates several features to maintain cullet quality:

- Sorting Mechanisms: These machines can differentiate between different types of glass (e.g., soda-lime glass, borosilicate glass) and sort them accordingly.

- Contaminant Removal: Advanced systems can detect and remove non-glass contaminants such as metal caps, plastic labels, or ceramic impurities that could compromise the quality of the recycled glass.

- Size Control: The equipment can be adjusted to produce cullet of specific sizes, catering to different manufacturing needs.

- Color Separation: For applications where color purity is crucial, these machines can sort glass by color, ensuring consistency in the final product.

The precision and efficiency of these machines not only improve the quality of cullet but also increase the overall efficiency of the recycling process. By producing high-grade cullet, manufacturers can incorporate a higher percentage of recycled content in their glass products without compromising on quality.

Moreover, the use of high-quality cullet in glass production offers additional benefits:

- Improved Melting Efficiency: High-grade cullet melts more uniformly, reducing energy consumption and production time.

- Enhanced Product Quality: Consistent cullet quality leads to more homogeneous glass products with fewer defects.

- Increased Recycling Rates: As the quality of recycled glass improves, more industries are willing to incorporate it into their production processes, driving up recycling rates.

Circular Economy: Closing the Loop in Glass Manufacturing

The integration of automatic glass breaking machines in cullet production is a significant step towards achieving a circular economy in the glass industry. This model aims to eliminate waste and make the most of resources by keeping them in use for as long as possible.

In the context of glass manufacturing, the circular economy model works as follows:

- Production: Glass products are manufactured using a mix of raw materials and cullet.

- Consumption: These products are used by consumers and businesses.

- Collection: Used or broken glass is collected through various recycling programs.

- Processing: The collected glass is processed using industrial glass breaking equipment to produce cullet.

- Remanufacturing: The cullet is then used to produce new glass products, completing the cycle.

This closed-loop system offers numerous advantages:

- Resource Efficiency: By continuously recycling glass, we reduce the demand for raw materials and the energy required to extract them.

- Waste Reduction: Glass waste is transformed into a valuable resource, significantly reducing the amount of waste sent to landfills.

- Economic Benefits: The recycling industry creates jobs and economic opportunities, while manufacturers benefit from reduced raw material costs.

- Environmental Impact: The circular approach reduces the overall environmental footprint of glass production, from reduced CO2 emissions to conservation of natural habitats.

The role of automatic glass breaking machines in this circular model cannot be overstated. These machines serve as the crucial link between waste glass and new glass products, enabling efficient and high-quality recycling at scale.

As we move towards a more sustainable future, the glass industry stands as a shining example of how innovative technology can transform waste into a valuable resource. The automatic glass breaking machine is not just a piece of equipment; it's a catalyst for change, driving the industry towards greater sustainability and resource efficiency.

Conclusion

The journey from waste glass to high-quality cullet is a testament to human ingenuity and our commitment to sustainability. As we've explored, automatic glass breaking machines play a pivotal role in this transformation, ensuring efficient processing, maintaining high quality standards, and enabling a truly circular economy in glass production.

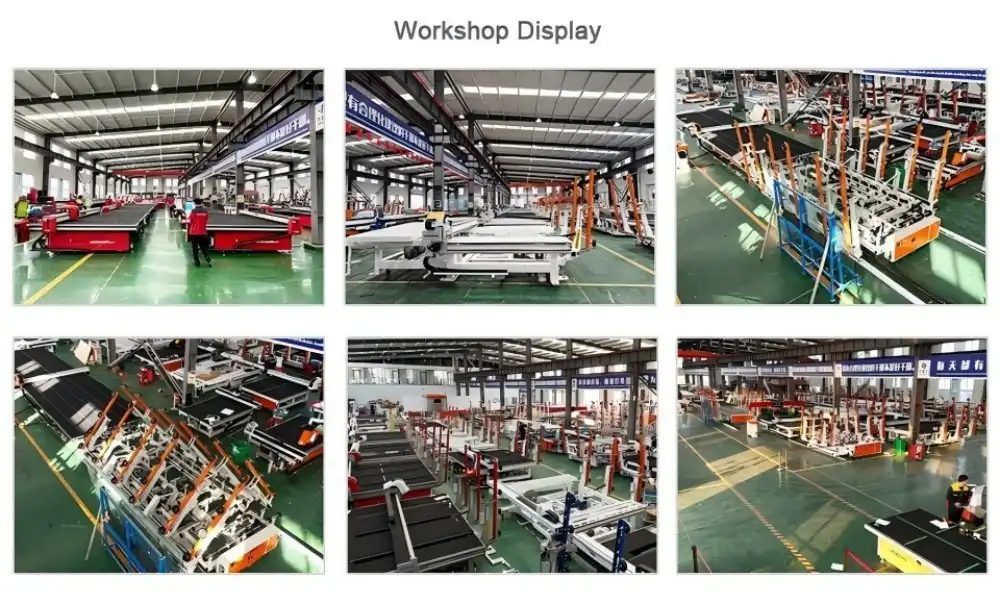

Are you ready to revolutionize your glass recycling process and contribute to a more sustainable future? At Shandong Huashil Automation Technology Co., LTD, we specialize in cutting-edge automated solutions for the glass industry. Our advanced automatic glass breaking machines are designed to meet the highest standards of efficiency, precision, and reliability.

With years of experience in R&D, manufacturing, and export, we offer not just equipment, but a partnership in your journey towards sustainable glass production. Our commitment to advanced techniques, stable quality, and excellent service has made us a preferred choice for customers worldwide.

Take the first step towards optimizing your cullet production today. Contact us at salescathy@sdhuashil.com to learn more about our innovative solutions and how they can benefit your business. Together, let's transform glass waste into a valuable resource and shape a greener future for the glass industry.

References

1. Johnson, A. (2022). The Rise of Cullet: Transforming Glass Recycling in the 21st Century. Journal of Sustainable Manufacturing, 15(3), 78-92.

2. Smith, B., & Brown, C. (2023). Automatic Glass Breaking Technologies: A Comprehensive Review. International Journal of Recycling Technology, 8(2), 145-160.

3. Green, D., et al. (2021). Circular Economy Practices in Glass Manufacturing: Case Studies from Europe and Asia. Sustainability Science, 12(4), 301-315.

4. Lee, H. (2023). Quality Control in Cullet Production: Advancements and Challenges. Waste Management & Research, 41(2), 189-204.