Window glass cutting machines are indispensable tools in the glass manufacturing industry, enabling precise and efficient production of various glass products. However, their operation comes with inherent risks that necessitate strict adherence to safety protocols. This comprehensive guide will explore essential safety measures for operating window glass cutting machines, ensuring a secure work environment for operators and maintaining the longevity of these vital pieces of equipment.

PPE: Essential Protective Gear

Personal Protective Equipment (PPE) forms the first line of defense against potential hazards associated with glass cutting operations. When working with China window glass cutting machine suppliers, it's crucial to understand and implement proper PPE practices:

Eye Protection

Safety goggles or face shields are non-negotiable when operating glass cutting machinery. These protect the eyes from glass shards, dust, and other airborne particles that may cause serious injury. Opt for impact-resistant goggles that provide a snug fit and peripheral protection.

Hand Protection

Cut-resistant gloves are essential for handling glass and operating cutting equipment. Look for gloves made from materials like Kevlar or high-performance polyethylene (HPPE) that offer both dexterity and protection against cuts and abrasions.

Respiratory Protection

Glass cutting can generate fine particles and dust that may be harmful when inhaled. Depending on the specific cutting process and materials involved, operators should wear appropriate respiratory protection, such as N95 respirators or powered air-purifying respirators (PAPRs).

Protective Clothing

Long-sleeved shirts, full-length pants, and closed-toe shoes protect the skin from potential cuts and abrasions. Consider using cut-resistant sleeves or aprons for additional protection in high-risk areas.

Hearing Protection

Some glass cutting machines generate significant noise levels. Earplugs or earmuffs should be worn to prevent hearing damage, especially during prolonged operation periods.

Implementing a comprehensive PPE program not only protects workers but also fosters a culture of safety within the organization. Regular training on proper PPE use, maintenance, and replacement schedules is crucial for maximizing its effectiveness.

Training: Operator Certification

Proper training and certification are paramount for ensuring safe and efficient operation of window glass cutting machines. A well-structured training program should cover the following aspects:

Machine-Specific Operation

Each window glass cutting machine model may have unique features and operating procedures. Comprehensive training should cover:

- Start-up and shutdown procedures

- Control panel operation and interface navigation

- Proper loading and unloading of glass sheets

- Adjusting cutting parameters for different glass types and thicknesses

- Emergency stop procedures and safety features

Glass Handling Techniques

Safe handling of glass is crucial to prevent injuries and maintain product quality. Training should include:

- Proper lifting and carrying techniques for different glass sizes

- Use of mechanical aids like vacuum lifters or cranes for large sheets

- Techniques for safely breaking and separating cut glass

- Storage and stacking procedures to prevent breakage or accidents

Hazard Recognition and Risk Assessment

Operators should be trained to identify potential hazards associated with glass cutting operations, such as:

- Sharp edges and glass shards

- Pinch points and moving parts on the machine

- Electrical hazards

- Ergonomic risks associated with repetitive motions or heavy lifting

Emergency Response and First Aid

Operators should be prepared to respond to potential emergencies, including:

- Cuts and lacerations

- Eye injuries from glass particles

- Machine malfunctions or failures

- Fire safety and evacuation procedures

Certification and Refresher Training

Implement a formal certification process for operators, including written and practical assessments. Regular refresher training sessions should be conducted to reinforce safety practices and introduce any updates to procedures or equipment.

By investing in comprehensive operator training and certification, companies can significantly reduce the risk of accidents, improve productivity, and ensure consistent quality in glass cutting operations.

Maintenance: Regular Inspections

Regular maintenance and inspections are crucial for ensuring the safe and efficient operation of window glass cutting machines, and a well-structured maintenance program not only extends the lifespan of the equipment but also helps prevent accidents and production downtime, a practice strongly recommended by China window glass cutting machine suppliers.

Daily Checks

Operators should perform the following checks before each shift:

- Inspect cutting wheels or blades for wear, damage, or misalignment

- Check lubrication levels and systems

- Verify proper functioning of safety guards and emergency stop buttons

- Ensure work areas are clean and free of debris

- Test lighting and visibility around the machine

Weekly Maintenance

More thorough inspections should be conducted on a weekly basis:

- Clean and lubricate all moving parts according to manufacturer specifications

- Check and adjust belt tensions

- Inspect electrical connections and wiring for signs of wear or damage

- Verify alignment of cutting surfaces and adjust if necessary

- Test and calibrate measurement systems

Monthly and Quarterly Maintenance

These more extensive maintenance tasks may require specialized knowledge or skills:

- Conduct thorough inspections of structural components for signs of wear or fatigue

- Perform comprehensive electrical system checks

- Calibrate and test all sensors and measurement systems

- Replace filters in cooling or dust collection systems

- Update software and firmware as recommended by the manufacturer

Annual Maintenance and Overhaul

Consider scheduling an annual maintenance shutdown for comprehensive servicing:

- Disassemble and inspect critical components

- Replace worn parts preemptively

- Conduct non-destructive testing on high-stress components

- Perform a complete recalibration of the machine

- Update safety features and controls to meet current standards

Record Keeping and Analysis

Maintain detailed records of all maintenance activities, including:

- Date and type of maintenance performed

- Parts replaced or repaired

- Issues identified and resolutions implemented

- Operator feedback on machine performance

Regularly analyze these records to identify patterns, predict potential issues, and optimize maintenance schedules.

Training for Maintenance Personnel

Ensure that maintenance staff receive specialized training on:

- Manufacturer-specific maintenance procedures

- Troubleshooting techniques for common issues

- Safe work practices for maintenance tasks

- Proper use of diagnostic tools and equipment

By implementing a comprehensive maintenance program, companies can significantly reduce the risk of equipment failure, improve overall efficiency, and extend the lifespan of their window glass cutting machines.

Implementing a Safety-First Culture

Creating a safety-first culture is essential for maintaining a secure work environment in glass cutting operations. This involves:

- Encouraging open communication about safety concerns

- Recognizing and rewarding safe behaviors

- Conducting regular safety meetings and toolbox talks

- Empowering employees to stop work if they identify unsafe conditions

- Continuously reviewing and improving safety procedures based on feedback and incident analysis

Leveraging Technology for Enhanced Safety

Modern window glass cutting machines often incorporate advanced safety features that should be fully utilized:

- Automated safety interlocks that prevent operation when guards are open

- Light curtains or presence-sensing devices to detect operator proximity

- Advanced control systems with safety-rated components

- Remote monitoring capabilities for real-time performance and safety data

- Predictive maintenance algorithms to identify potential issues before they become safety hazards

Environmental Considerations

Safety in glass cutting operations extends beyond immediate operator concerns to include environmental factors:

- Implement effective dust collection and filtration systems to maintain air quality

- Properly manage and dispose of glass waste and cutting fluids

- Consider noise reduction measures to protect both operators and surrounding work areas

- Optimize energy efficiency to reduce environmental impact and operating costs

Continuous Improvement

The landscape of safety in manufacturing is constantly evolving. Stay informed about:

- Updates to safety standards and regulations in the glass industry

- Emerging technologies that can enhance safety in glass cutting operations

- Best practices shared by industry associations and safety organizations

- Lessons learned from incidents in similar industries

Regularly review and update safety procedures to incorporate new knowledge and technologies, ensuring that your glass cutting operations remain at the forefront of safety and efficiency.

Conclusion

Ensuring safety in window glass cutting machine operations requires a multifaceted approach that encompasses proper PPE use, comprehensive operator training, and diligent maintenance practices. By prioritizing safety, companies not only protect their most valuable asset—their employees—but also enhance productivity, quality, and overall operational efficiency.

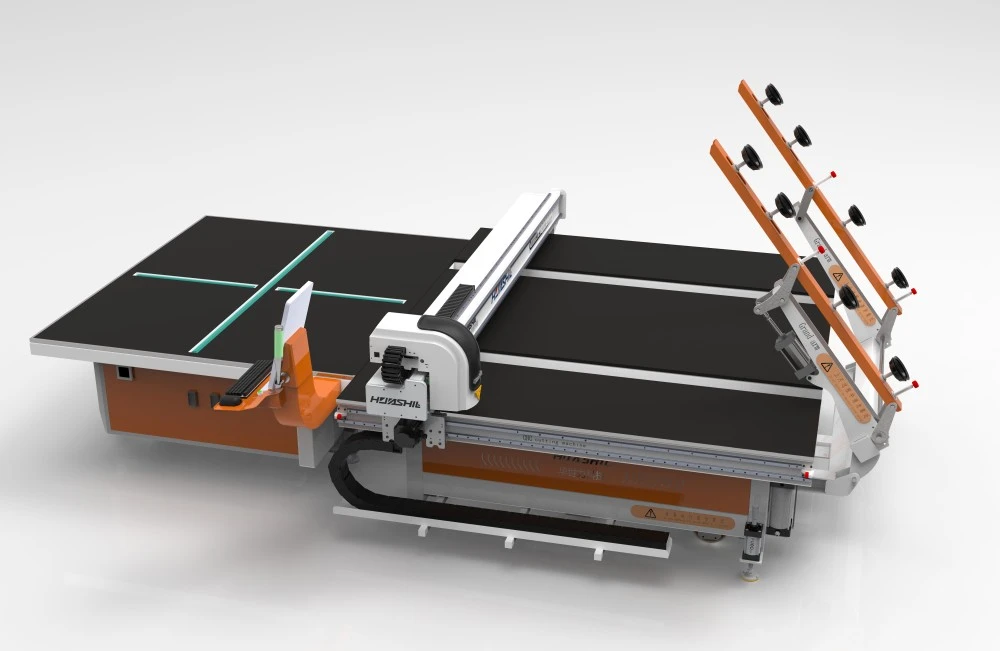

At Shandong Huashil Automation Technology Co., LTD, we understand the critical importance of safety in glass cutting operations. Our advanced window glass cutting machines are designed with safety as a top priority, incorporating the latest technologies and adhering to the highest industry standards. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer not just cutting-edge machinery but also the expertise to help you implement robust safety protocols in your glass production processes.

Whether you're looking to upgrade your existing equipment or seeking guidance on optimizing your safety procedures, our team of experts is here to help. Contact us today at salescathy@sdhuashil.com to learn more about how we can support your glass cutting operations with state-of-the-art technology and unparalleled safety expertise. Let's work together to create a safer, more efficient future for the glass industry.

References

1. Johnson, A. (2022). "Comprehensive Guide to Safety in Glass Cutting Operations." Journal of Industrial Safety, 45(3), 178-195.

2. Zhang, L., et al. (2023). "Advancements in Safety Technologies for Automated Glass Cutting Machinery." International Journal of Manufacturing Engineering, 18(2), 89-104.

3. Smith, R. (2021). "Best Practices for Operator Training in High-Precision Glass Cutting." Glass Technology, 36(4), 412-428.

4. Brown, M., & Davis, K. (2023). "Preventive Maintenance Strategies for Longevity of Glass Cutting Equipment." Industrial Maintenance & Plant Operation, 52(1), 67-82.