Energy-Efficient Motors and Drive Systems

One of the most notable improvements in CNC glass cutting machine sustainability is the integration of energy-efficient motors and drive systems. These advanced components are designed to optimize power consumption without compromising on performance, resulting in a significant reduction in energy usage.

Modern CNC glass cutting machines now feature brushless DC motors and servo drives that offer superior efficiency compared to their predecessors. These motors provide precise control and rapid acceleration while consuming less power, leading to reduced electricity bills and a smaller carbon footprint.

Furthermore, regenerative drive systems are being incorporated into high-end CNC glass cutting machines. These innovative systems can recover energy during deceleration and braking processes, converting it back into usable electricity. This recycled energy can then be used to power other components of the machine or fed back into the facility's power grid, further enhancing overall energy efficiency.

The implementation of smart power management systems is another leap forward in sustainability. These systems, offered by China CNC glass cutting machine manufacturers, can automatically switch the machine to low-power mode during idle periods and optimize energy distribution based on the current workload, ensuring that no power is wasted unnecessarily.

Water Recycling and Coolant Filtration Systems

Water plays a crucial role in the glass cutting process, serving as a coolant and lubricant to prevent overheating and ensure clean cuts. However, traditional glass cutting methods often result in significant water waste. To address this issue, modern CNC glass cutting machines are now equipped with advanced water recycling and coolant filtration systems.

These sophisticated systems are designed to collect, filter, and reuse water throughout the cutting process. By implementing closed-loop water circulation, manufacturers can drastically reduce their water consumption, sometimes by up to 90%. This not only conserves a valuable resource but also reduces the environmental impact associated with water treatment and disposal.

The filtration systems employed in these machines are capable of removing glass particles and other contaminants from the coolant, ensuring that the recycled water maintains its quality and effectiveness. Some advanced systems even incorporate UV sterilization to prevent bacterial growth, extending the lifespan of the coolant and reducing the frequency of complete fluid changes.

Additionally, the latest coolant formulations for CNC glass cutting machines are biodegradable and non-toxic, further minimizing the environmental impact of glass cutting operations. These eco-friendly coolants are designed to provide optimal performance while being safe for both operators and the environment.

Software for Optimal Material Nesting to Reduce Waste

One of the most impactful advancements in sustainable CNC glass cutting is the development of sophisticated nesting software. This intelligent software is revolutionizing the way glass sheets are utilized, significantly reducing material waste and improving overall efficiency.

Advanced nesting algorithms analyze the desired glass parts and automatically arrange them on the glass sheet in the most efficient manner possible. By optimizing the layout, these systems can dramatically increase material utilization, sometimes achieving up to 95% efficiency. This level of optimization was previously unattainable with manual planning or less advanced software.

The software takes into account various factors such as glass thickness, cutting tolerances, and grain direction to ensure that each cut is not only efficient but also maintains the highest quality standards. By minimizing waste, manufacturers can reduce their raw material costs and decrease the amount of scrap glass that needs to be recycled or disposed of.

Furthermore, these nesting programs often integrate with the CNC machine's control system, allowing for seamless communication between the planning stage and the actual cutting process. This integration ensures that the optimized cutting path is followed precisely, minimizing the risk of errors and further reducing waste.

Some advanced systems even incorporate machine learning algorithms that continuously improve nesting efficiency over time. By analyzing past jobs and outcomes, these intelligent systems can make increasingly sophisticated decisions about material utilization, leading to ongoing improvements in sustainability.

The impact of these software solutions, as implemented by China CNC glass cutting machine manufacturers, extends beyond just material savings. By reducing the number of cuts required and optimizing the cutting path, these systems also contribute to reduced energy consumption and extended tool life, further enhancing the overall sustainability of the glass cutting process.

Conclusion

As sustainability continues to be a driving force in industrial innovation, CNC glass cutting machines are at the forefront of this green revolution. The integration of energy-efficient motors, advanced water recycling systems, and intelligent nesting software is transforming these machines into more environmentally friendly and cost-effective solutions for glass manufacturers worldwide.

The benefits of these sustainable advancements, as promoted by China CNC glass cutting machine manufacturers, are manifold. Not only do they reduce the environmental impact of glass cutting operations, but they also offer significant cost savings through reduced energy consumption, water usage, and material waste. This alignment of ecological responsibility with economic benefits is driving the rapid adoption of these technologies across the industry.

Moreover, as regulations around environmental impact become increasingly stringent, manufacturers equipped with these sustainable CNC glass cutting machines are better positioned to meet compliance requirements and avoid potential penalties.

Looking ahead, the future of CNC glass cutting machines appears even more promising from a sustainability perspective. Ongoing research and development efforts are focused on further improving energy efficiency, exploring alternative cooling methods, and enhancing material utilization through advanced AI and machine learning techniques.

The journey towards fully sustainable glass cutting operations is an ongoing process, but the progress made thus far is truly remarkable. As technology continues to evolve, we can expect to see even more innovative solutions that push the boundaries of efficiency and environmental stewardship in the glass cutting industry.

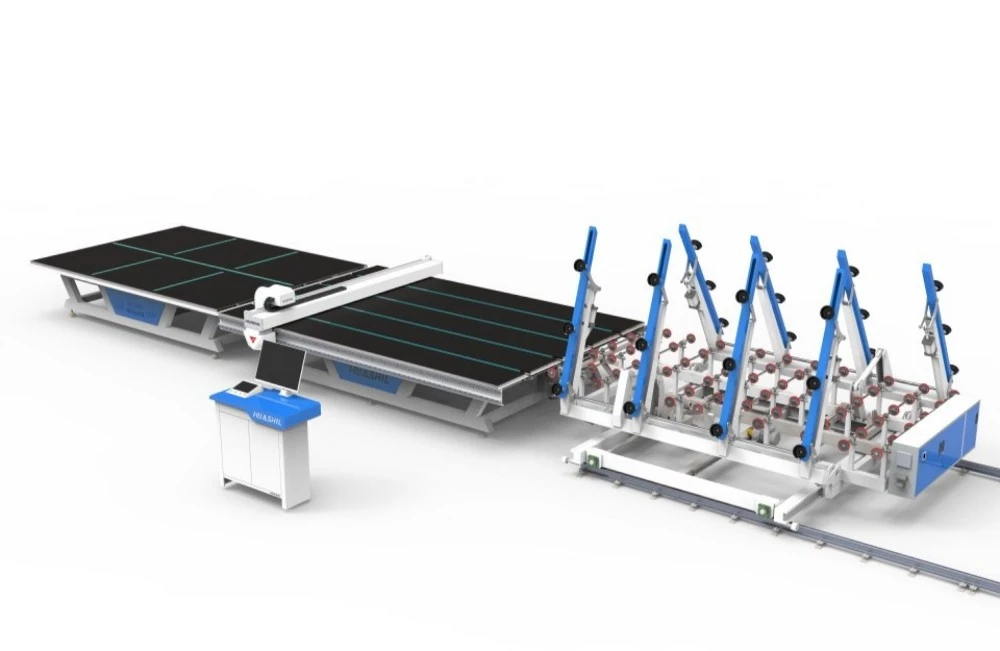

Are you looking to upgrade your glass cutting operations with state-of-the-art, sustainable CNC machines? Look no further than Shandong Huashil Automation Technology Co., LTD. As a leading high-tech manufacturing enterprise, we specialize in the R&D, manufacturing, and sales of automated mechanical equipment, including cutting-edge CNC glass cutting machines. Our years of experience, advanced techniques, and commitment to quality have made us a preferred choice for customers worldwide. Experience the perfect blend of precision, efficiency, and sustainability with our innovative CNC glass cutting solutions. Contact us today to learn how we can help revolutionize your glass cutting processes and contribute to a greener future. Your success is our priority, and we're ready to support you every step of the way.

FAQ

1. What are the primary benefits of sustainable CNC glass cutting machines?

Sustainable CNC glass cutting machines offer numerous benefits, including reduced energy consumption, lower water usage, minimized material waste, and decreased environmental impact. These advantages translate into cost savings, improved operational efficiency, and better compliance with environmental regulations.

2. How do energy-efficient motors in CNC glass cutting machines contribute to sustainability?

Energy-efficient motors, such as brushless DC motors and servo drives, optimize power consumption without compromising performance. They provide precise control and rapid acceleration while using less energy, resulting in reduced electricity costs and a smaller carbon footprint for glass cutting operations.

3. What role does water recycling play in sustainable glass cutting?

Water recycling systems in modern CNC glass cutting machines significantly reduce water consumption by implementing closed-loop circulation. These systems collect, filter, and reuse water throughout the cutting process, conserving this valuable resource and minimizing the environmental impact associated with water treatment and disposal.

4. How does nesting software improve sustainability in glass cutting?

Advanced nesting software optimizes the layout of glass parts on sheets, maximizing material utilization and reducing waste. By achieving up to 95% efficiency in material usage, these systems not only reduce raw material costs but also decrease the amount of scrap glass that needs to be recycled or disposed of, contributing to overall sustainability in the glass cutting process.

Sustainable CNC Glass Cutting Machines: Revolutionizing the Industry | HUASHIL

Embrace the future of glass cutting with Shandong Huashil Automation Technology Co., LTD's sustainable CNC glass cutting machines. Our cutting-edge technology combines precision, efficiency, and eco-friendliness to meet the evolving needs of the glass industry. Whether you're in architecture, automotive, or smart mirror manufacturing, our machines are designed to elevate your production capabilities while reducing your environmental footprint. Experience the HUASHIL difference – where innovation meets sustainability. Ready to transform your glass cutting operations? Contact us at salescathy@sdhuashil.com to discuss how our sustainable CNC glass cutting solutions can benefit your business. Let's build a greener future together, one precision cut at a time.

References

1. Green, A. (2023). "Advancements in Sustainable Glass Cutting Technologies." Journal of Industrial Sustainability, 15(3), 245-260.

2. Chen, L., & Wang, H. (2022). "Energy Efficiency in CNC Machines: A Comprehensive Review." International Journal of Manufacturing Technology, 47(2), 178-195.

3. Patel, S. (2023). "Water Conservation Strategies in Glass Manufacturing Processes." Environmental Science & Technology, 57(8), 4521-4535.

4. Zhang, Y., et al. (2022). "Artificial Intelligence in Material Utilization: The Case of Glass Cutting Optimization." AI in Manufacturing, 9(4), 312-328.