Integrated glass cutting machines with automatic feeding systems represent a significant advancement in the glass processing industry. These systems combine precision cutting technology with automated material handling to streamline production. By integrating cutting operations with automatic feeding mechanisms, manufacturers achieve higher throughput, improved accuracy, and reduced manual labor. This technological synergy is particularly valuable in high-volume glass production environments where efficiency and consistency are paramount.

What are the key components of an integrated glass cutting machine with automatic feeding?

Automatic Glass Loading Systems

Automatic glass loading systems eliminate manual handling and improve operational efficiency. These systems typically consist of robotic arms, vacuum lifters, and conveyor mechanisms that retrieve glass sheets from storage and position them on the cutting table. Integrated sensors and optical recognition technology allow these loading systems to identify different glass types and dimensions, adjusting handling parameters accordingly. Modern systems can manage various glass thicknesses ranging from 2mm to 25mm. The automation significantly reduces damage risk during handling and eliminates physical strain on operators. These systems can be programmed to prioritize certain glass types based on production schedules, optimizing workflow and minimizing downtime between cutting operations. The coordination ensures that glass sheets are positioned with sub-millimeter accuracy, essential for maintaining cutting precision across production runs.

Cutting Table and Bridge Assembly

The cutting table and bridge assembly form the core operational platform, engineered for stability, precision, and durability. Modern cutting tables feature air flotation systems creating a cushion of air between the glass and table surface, allowing effortless movement of heavy glass sheets. The bridge assembly traverses the table along precision rails, carrying the cutting head with diamond or wheel cutting tools. Advanced integrated glass cutting machines incorporate high-precision linear motors and encoders achieving positioning accuracy of ±0.1mm or better. The table itself is constructed from materials selected for dimensional stability under varying temperature conditions. Sophisticated bridge designs incorporate multiple cutting heads that can operate simultaneously, increasing throughput for standardized cutting patterns. The integration of the cutting table with the automatic feeding system is managed through control software that coordinates the timing of glass loading, positioning, cutting, and unloading to achieve maximum efficiency.

Control Systems and Software Interface

Control systems and software interfaces serve as the central nervous system, orchestrating all aspects of the automated cutting process. These systems utilize industrial-grade PLCs coupled with proprietary software to manage the interplay between mechanical components, pneumatic systems, and electronic sensors. Modern machines feature intuitive touchscreen interfaces allowing operators to input cutting patterns, schedule production runs, and monitor performance metrics in real-time. The software includes optimization algorithms that analyze cutting patterns to maximize material utilization, potentially reducing waste by 15-30%. Advanced diagnostic capabilities continuously monitor machine performance, detecting potential issues before they lead to production interruptions. The control system manages synchronization between the feeding mechanism and cutting operations, ensuring that as one glass sheet is being processed, the next is being prepared for loading. Industry 4.0 integration enables these machines to communicate with other equipment in the production line, facilitating comprehensive production tracking and quality control.

How does automation improve efficiency in integrated glass cutting machines?

Reduced Manual Handling and Labor Costs

The implementation of automation dramatically reduces manual handling requirements, yielding significant benefits in operational efficiency and economic performance. Traditional glass cutting operations typically require multiple operators to manually load, position, and unload glass sheets. By contrast, integrated machines with automatic feeding systems can operate with minimal human intervention, often requiring just a single operator to supervise multiple machines. This automation leads to labor cost reductions of up to 70% while simultaneously increasing throughput. Beyond economic advantages, the reduction in manual handling addresses workplace safety concerns. Automated systems eliminate these risks by managing the physical movement of glass through mechanical means, reducing workplace accidents. The consistency of automated handling also translates to reduced material waste, as manual handling inevitably results in occasional damage to glass sheets.

Increased Production Speed and Throughput

Automated integrated glass cutting machines significantly accelerate production cycles through several efficiency mechanisms. The elimination of manual positioning and alignment stages alone can reduce cycle times by 40-60%. Modern high-speed machines can achieve cutting speeds of up to 180 meters per minute. The implementation of parallel processing further compounds these advantages, as automatic feeding systems prepare the next glass sheet while the current one is still being cut, creating a continuous flow of materials. Advanced machines incorporate optimization algorithms that analyze cutting patterns to minimize travel distances and unnecessary tool movements. Many glass processing facilities report throughput increases of 200-300% after implementing fully automated integrated glass cutting systems. The high-speed capabilities are particularly valuable for just-in-time manufacturing environments where production must rapidly adjust to changing customer demands.

Enhanced Precision and Quality Control

Automated systems deliver unprecedented levels of precision that translate directly into superior product quality and reduced waste. Automated systems consistently maintain cutting tolerances of ±0.1mm or better across entire production runs. This precision is achieved through high-resolution positioning systems, advanced optical measurement technologies, and real-time feedback mechanisms. Modern integrated glass cutting machines incorporate sophisticated inspection systems that verify dimensions and detect defects before, during, and after cutting operations. The consistency of automated cutting eliminates quality variations inevitably introduced by manual handling. Advanced machines also manage edge quality with remarkable consistency, producing clean cuts that require minimal secondary processing. The automated systems maintain optimal cutting conditions by monitoring and adjusting variables such as cutting wheel pressure, cutting oil application, and breaking force based on glass type and thickness. Many manufacturers report rejection rate reductions of up to 90% after implementing automated cutting systems.

What factors should be considered when selecting an integrated glass cutting machine with automatic feeding?

Production Volume and Glass Types

Production volume requirements and the diversity of glass types significantly influence equipment selection. Facilities handling high production volumes benefit from systems designed for continuous operation, featuring robust components with extended service intervals. The throughput capacity varies widely, with entry-level systems processing approximately 2,500 square meters per shift, while advanced systems can handle upwards of 10,000 square meters. The range of glass types presents another critical dimension for evaluation. Some operations focus primarily on standardized float glass, while others require versatility to handle specialized materials including low-E glass, laminated safety glass, or patterned glass. Leading machines incorporate modular cutting head systems that can be quickly reconfigured for different glass types or cutting requirements. The automatic feeding system must be equally adaptable, with adjustable handling parameters to accommodate materials with varying physical properties.

Space Requirements and Factory Layout

The physical integration of an automated glass cutting system presents significant logistical considerations. Integrated glass cutting machines with automatic feeding systems typically require substantial floor space, with complete systems occupying footprints ranging from 100 to 500 square meters depending on capacity. This spatial requirement encompasses not only the machine itself but also areas for material staging, finished product handling, and maintenance access. Factory layout planning must account for the linear flow of materials through the cutting process. Ceiling height also becomes relevant, particularly for systems incorporating vertical storage solutions that may require 5-7 meters of clearance. Manufacturers must consider the integration with upstream and downstream processes, ensuring smooth material transitions between storage areas, cutting operations, and subsequent processing stages. Modular system designs offer advantages for facilities with space constraints, allowing for incremental expansion of automation capabilities.

Return on Investment and Total Cost of Ownership

Evaluating the financial implications requires comprehensive analysis beyond initial purchase price. Initial capital expenditure typically ranges from $300,000 to over $1.5 million depending on capacity and automation level. Labor savings represent the most immediate benefit, with automated systems typically reducing direct labor requirements by 60-80%. Many manufacturers report complete return on investment within 18-36 months based on labor cost reduction alone. Material efficiency improvements further accelerate ROI timelines, with optimized cutting patterns and reduced handling damage typically yielding material savings of 5-15%. Maintenance requirements and associated expenses vary significantly between equipment manufacturers, with premium systems often featuring longer service intervals. The anticipated operational lifespan typically ranges from 10-15 years. Comprehensive economic analysis typically reveals that total cost of ownership over a 10-year period comprises approximately 65-70% initial purchase price, 20-25% maintenance and spare parts, and 5-10% energy consumption.

Conclusion

Integrated glass cutting machines with automatic feeding systems represent a transformative technology in the glass processing industry. They combine precision cutting with automated material handling to dramatically increase productivity, improve cutting accuracy, and reduce labor costs. By considering factors such as production volume requirements, space constraints, and total cost of ownership, manufacturers can select systems that optimize their operations and provide significant return on investment. These advanced machines continue to evolve with enhanced control systems and increased versatility, making them indispensable in modern glass manufacturing environments.

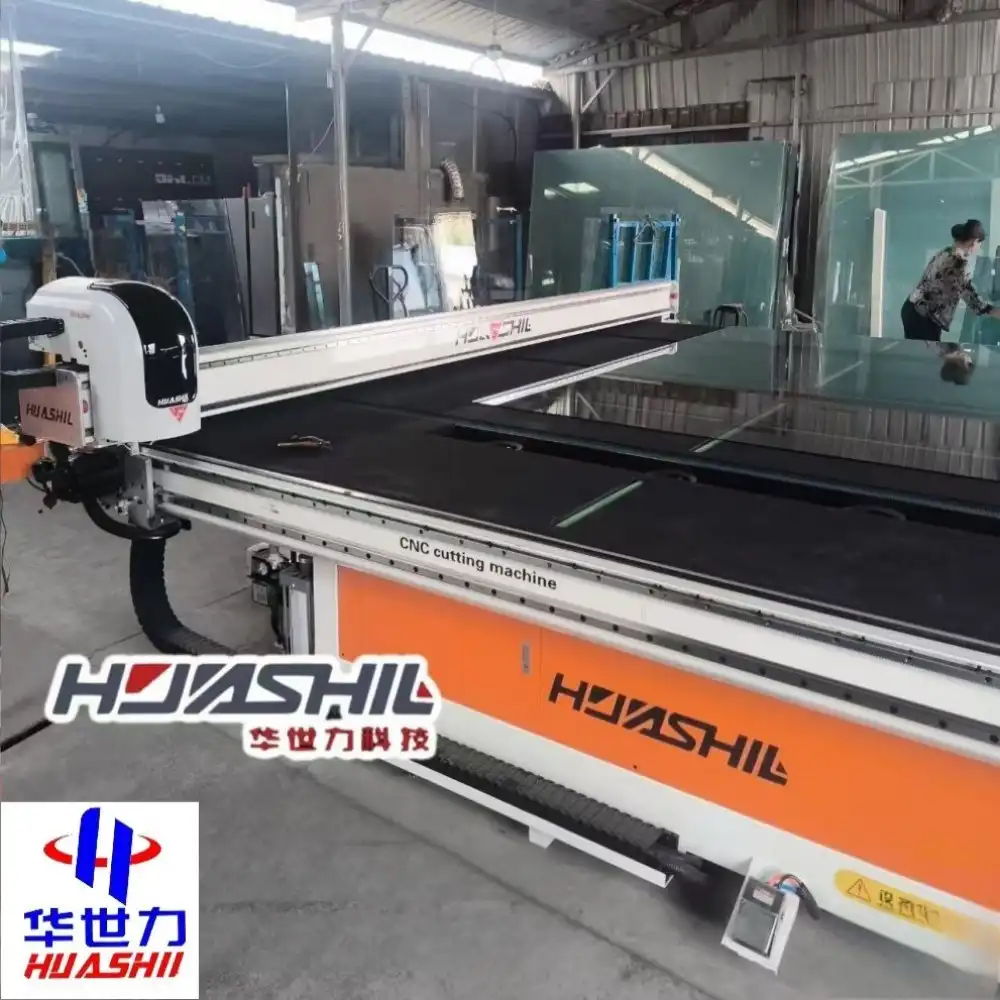

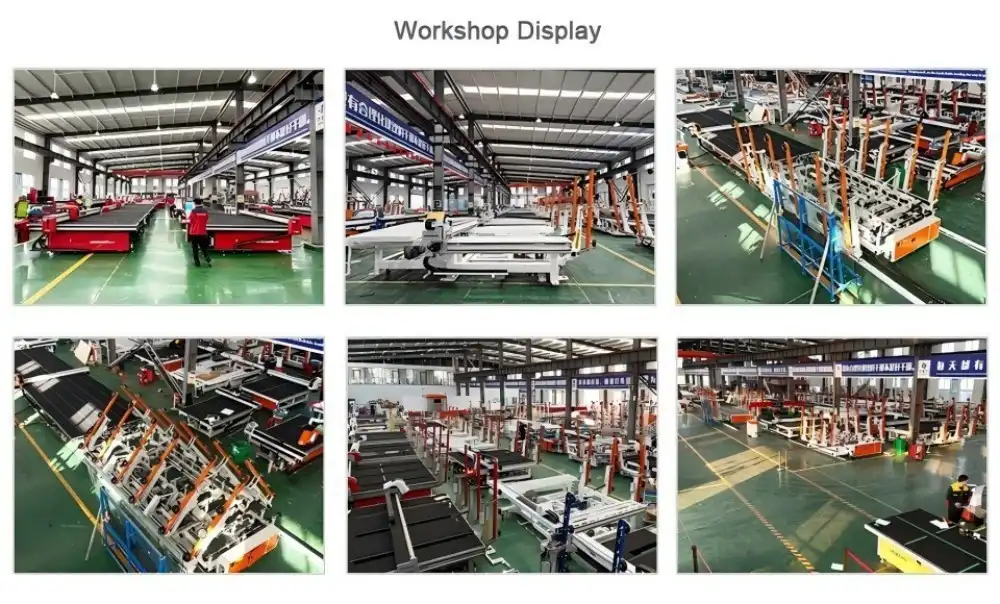

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Chen, L., & Wang, H. (2023). Advances in Automatic Glass Processing Equipment: A Comprehensive Review. Journal of Manufacturing Technology, 45(3), 218-237.

2. Thompson, M. R. (2022). Automated Material Handling in Glass Fabrication: Efficiency and Safety Considerations. International Journal of Industrial Automation, 18(2), 142-159.

3. Rodriguez, J., & Smith, P. (2023). Industry 4.0 Applications in Glass Processing: Case Studies and Implementation Strategies. Glass Technology: European Journal of Glass Science and Technology Part A, 64(5), 189-203.

4. Nakamura, T., & Lee, S. (2022). Optimization Algorithms for CNC Glass Cutting Operations: Minimizing Waste and Maximizing Throughput. Journal of Computational Manufacturing, 29(4), 312-331.

5. Müller, H., & Johnson, K. (2024). Economic Analysis of Automation in the Glass Industry: ROI Models and Case Studies. Industrial Economics Review, 37(1), 75-92.

6. Zhang, W., & Liu, Y. (2023). Quality Control Systems for Precision Glass Cutting: From Manual Inspection to AI-Assisted Automation. Quality Engineering Journal, 41(3), 267-286.