Creating stained glass art requires precision and patience, with the cutting phase significantly impacting project quality and completion time. Artisans must choose between traditional hand-cutting methods or modern stained glass cutting machines. The time difference between these approaches varies considerably, and understanding these differences helps artists make informed decisions about workflow and equipment investments.

What are the time-saving benefits of using a stained glass cutting machine?

Precision Cutting Efficiency

The primary time-saving benefit of a stained glass cutting machine is its precision and consistency. Computerized cutting machines achieve perfectly straight lines and exact angles with minimal effort. The machine follows pre-programmed paths, eliminating human error and the need for repeated attempts. A professional-grade stained glass cutting machine can process complex patterns in minutes that might take an experienced artisan hours to complete manually. Intricate designs with numerous small pieces can be cut with consistent precision, reducing material waste and rework time. This efficiency is particularly valuable for commercial studios handling large-scale projects where consistency across multiple identical pieces is essential.

Batch Processing Capabilities

Modern stained glass cutting machines can process multiple pieces simultaneously. They can be programmed to cut identical patterns repeatedly or create multiple different components in a single operation. This batch processing capability dramatically reduces production time for commercial applications. A cutting machine with multi-head capabilities can process several glass sheets at once, effectively multiplying production output without additional labor hours. This feature benefits studios producing architectural elements where dozens or hundreds of identical pieces might be needed. The machine can run continuously with minimal operator intervention, allowing artists to focus on design work or assembly while cutting continues automatically.

Reduced Physical Fatigue

Using a stained glass cutting machine reduces the physical demands on the artist, indirectly saving time in production. Hand-cutting requires sustained physical effort and concentration, leading to fatigue over extended periods. As fatigue increases, cutting speed decreases and errors rise. Cutting machines maintain consistent speed and pressure regardless of job duration. Artists can program the machine to complete complicated tasks without experiencing hand strain, eye fatigue, or back pain associated with manual cutting. This reduced physical burden allows longer working hours without sacrificing quality. Additionally, machine performance makes production schedules more predictable, enabling better project planning.

How do stained glass cutting machines compare to hand cutting for different project sizes?

Small-Scale Project Comparison

For small projects with fewer than 20 pieces, the time advantage of a cutting machine exists but is less dramatic. An experienced artisan might hand-cut a simple design in 1-2 hours, while a properly set up machine could complete the same task in 15-30 minutes. However, this calculation must include setup time, which involves programming and calibration. The machine still provides benefits for designs with curved lines or unusual angles. Small production runs of the same design see greater time savings as setup time is spread across multiple iterations. Many hobbyists find their cutting machine becomes increasingly valuable as they take on more complex projects or produce multiple copies of popular designs.

Medium-Scale Project Efficiency

Medium-sized projects with 20-100 pieces demonstrate a more dramatic time difference. Hand cutting all components might require 8-15 hours spread over several days, while a cutting machine could complete the same work in 1-3 hours. This significant reduction allows artists to take on more projects or focus on artistic aspects like glass selection and assembly. The machine also reduces errors and material waste. For studios regularly producing medium-sized projects, the consistent output quality and predictable timeline can be essential for business planning and client satisfaction. Many professional studios report increased capacity by 200-300% for medium-scale projects compared to hand-cutting methods.

Large-Scale Commercial Production

For large projects with hundreds or thousands of pieces, a stained glass cutting machine becomes virtually indispensable. Hand cutting such massive projects could take weeks or months, whereas industrial-grade machines can process the same volume in days. Time savings extend beyond cutting to the entire workflow—design modifications can be implemented quickly and production schedules become more reliable. Many commercial studios operate multiple machines simultaneously to handle large projects. The machine allows for division of labor, where technicians operate the equipment while master craftspeople focus on design and assembly. This optimization further reduces project timeline and increases studio capacity. Consistency also becomes increasingly valuable at larger scales, where even small variations would be noticeable.

What factors affect the cutting speed of a stained glass cutting machine?

Technical Specifications and Machine Quality

Cutting speed varies significantly based on technical specifications and overall quality. Entry-level machines typically operate at slower speeds (100-300 mm/second) compared to professional equipment that can achieve speeds of 500-1000 mm/second or higher. Higher-end machines feature more powerful motors, precision-engineered components, and advanced control systems enabling faster operation without sacrificing accuracy. The cutting head design impacts speed—machines with automated pressure adjustment maintain optimal cutting pressure regardless of speed. Cutting wheel quality affects how quickly the machine can process different types of glass. Some advanced machines include multiple cutting heads working simultaneously, effectively multiplying production speed. When evaluating machines, consider not just maximum cutting speed but practical operational speed for various glass types.

Glass Type and Thickness Considerations

Different glass types and thicknesses require different cutting approaches, impacting time efficiency. Standard window glass (2-3mm) can be cut quickly, while thicker art glass (4-6mm) requires slower speeds to ensure clean breaks. Specialty glasses like opalescent or textured varieties present additional challenges. Heavily textured glass often requires slower speeds and higher pressure settings to score properly. The machine must be programmed accordingly, which may extend processing time compared to cutting uniform sheet glass. Some advanced machines automatically adjust cutting parameters based on the glass type detected. When calculating production timelines, operators must factor in these material considerations rather than relying solely on maximum speed specifications.

Software and Programming Complexity

Design complexity and control software sophistication determine how long a cutting machine takes to complete a project. Modern CNC machines use specialized software to translate designs into cutting paths. The efficiency of this translation significantly impacts production time. Advanced software can determine the most efficient cutting sequence, minimize tool travel distance, and optimize parameters for different sections. Some systems analyze patterns to identify potential stress points and adjust accordingly. The operator's programming expertise affects efficiency—experienced programmers create toolpaths that maximize machine capabilities while minimizing unnecessary movements. For complex projects, initial programming time might be substantial but pays dividends through optimized cutting efficiency.

Conclusion

The time difference between using a stained glass cutting machine and hand cutting is substantial, with machines offering significant advantages in speed, precision, and consistency. While hand cutting preserves traditional craftsmanship, modern cutting machines provide efficiency that transforms production capabilities, especially for commercial applications and complex designs. The choice between methods ultimately depends on project requirements, production volume, and desired aesthetic quality, with many studios effectively combining both approaches.

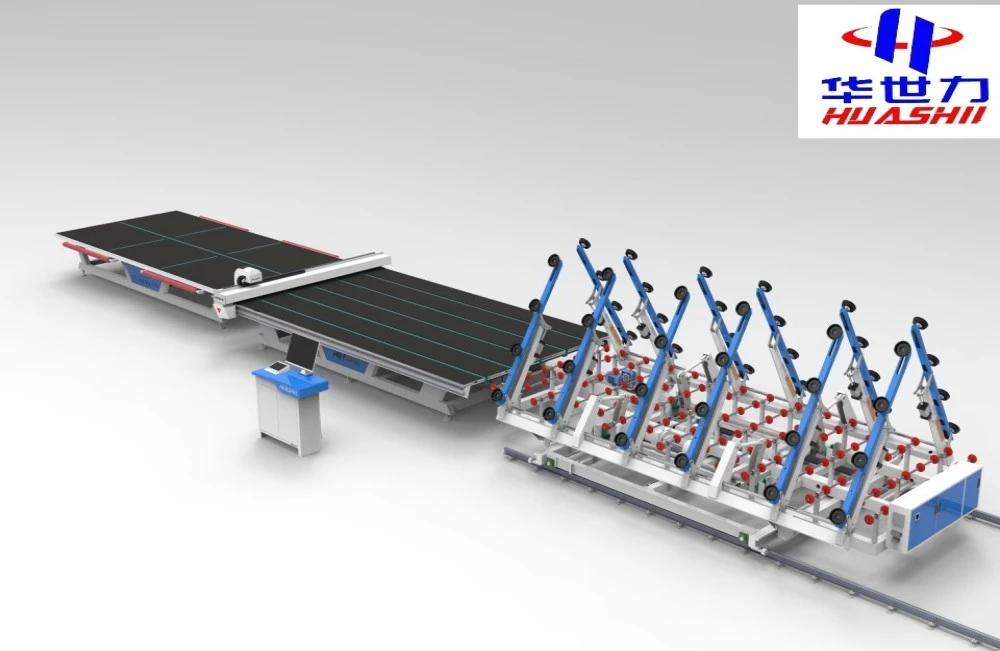

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Johnson, R. T. (2023). Modern Techniques in Stained Glass Production: Comparing Automated and Traditional Methods. Journal of Glass Art & Technology, 42(3), 145-159.

2. Williams, E. & Chang, S. (2022). Time Efficiency in Architectural Glass Processing: A Comparative Study of CNC Cutting Machines. International Glass Review, 18(2), 78-92.

3. Peterson, M. A. (2023). The Evolution of Stained Glass Cutting Technology: From Manual Tools to Digital Automation. Glass Technology Quarterly, 55(1), 23-37.

4. Garcia, L. & Thompson, D. R. (2022). Production Metrics in Contemporary Stained Glass Studios: Analysis of Time and Material Efficiency. Journal of Craft Economics, 29(4), 312-328.

5. Roberts, H. K. (2023). Industrial Applications of Automated Glass Cutting Systems in Decorative Arts. Technical Review of Glass Manufacturing, 47(2), 189-203.

6. Chen, Y. & Wilson, B. J. (2022). Comparative Analysis of Energy Efficiency in Traditional versus Machine-Assisted Stained Glass Production. Sustainable Craft Industries Journal, 15(3), 267-281.