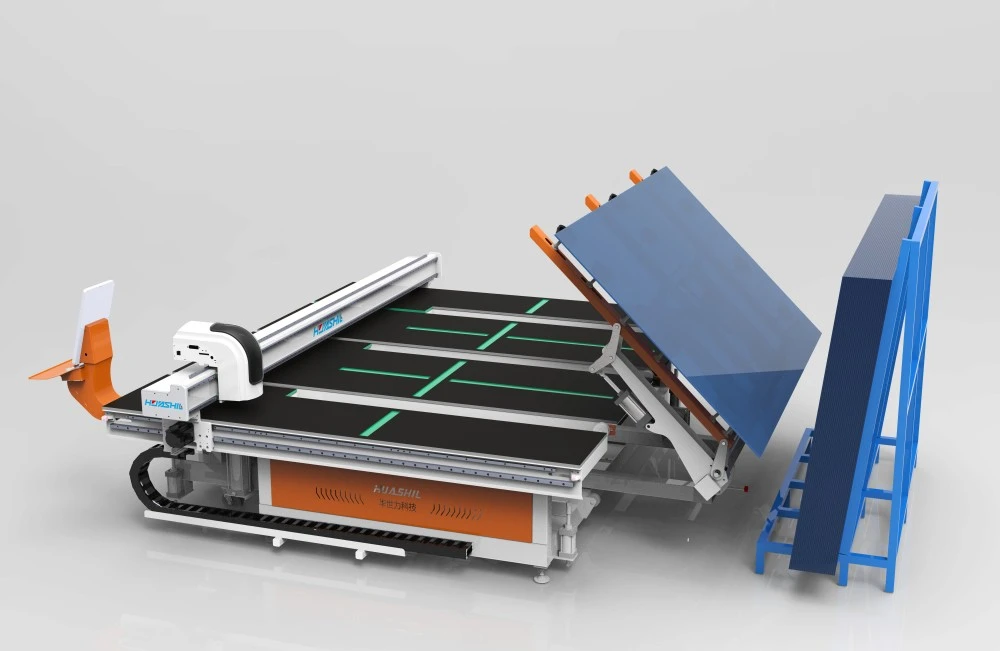

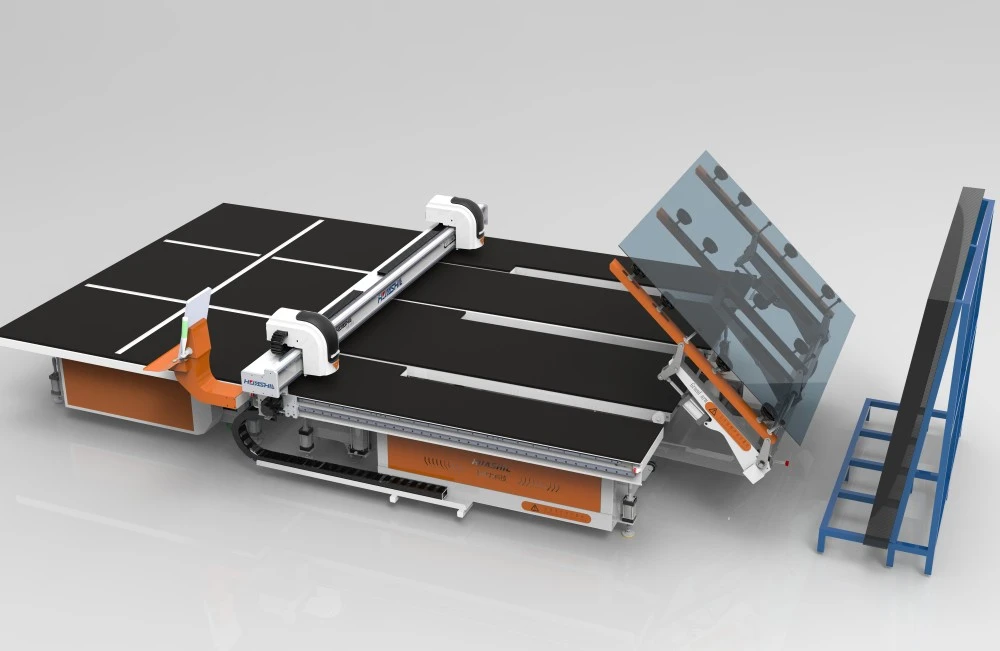

Auto glass cutting line machines are renowned for their precision and efficiency in processing various materials. While primarily designed for glass, these versatile machines can handle a range of substrates, making them indispensable in multiple industries. Let's delve into the materials that auto glass cutting line machines can process and explore their capabilities.

Beyond glass: Versatile cutting capabilities

Auto glass cutting line machines are not limited to just glass processing. These sophisticated pieces of equipment can cut and shape a variety of materials, including:

- Float glass

- Laminated glass

- Tempered glass

- Low-E glass

- Mirrored glass

- Patterned glass

- Acrylic sheets

- Polycarbonate panels

The ability to process such a wide range of materials makes auto glass cutting line machine factory products invaluable in industries beyond automotive manufacturing. These machines find applications in architecture, interior design, solar panel production, and even in the creation of high-tech smart mirrors.

For instance, in the architectural sector, these machines can cut large sheets of glass for curtain walls or intricate patterns for decorative glass installations. In the solar industry, they precision-cut photovoltaic glass to exact specifications, ensuring optimal energy capture and conversion efficiency.

The versatility of these machines extends to their ability to handle different glass compositions. Whether it's soda-lime glass, borosilicate glass, or specialty glasses with unique chemical compositions, auto glass cutting line machines can be calibrated to deliver precise cuts without compromising the material's integrity.

Moreover, these machines can process glass with various surface treatments. This includes glass with anti-reflective coatings, self-cleaning properties, or even smart glass that can change its opacity. The cutting process is designed to maintain the integrity of these special coatings, ensuring that the final product retains its intended properties.

Thickness range: From thin to robust

One of the most impressive features of auto glass cutting line machines is their ability to handle a wide range of material thicknesses. This flexibility allows manufacturers to cater to diverse market needs without investing in multiple specialized machines.

Typically, these machines can process materials ranging from ultra-thin sheets of 0.3mm to thick panels of up to 25mm. This broad spectrum encompasses:

- Thin glass (0.3mm - 2mm): Used in electronic displays, touchscreens, and lightweight architectural applications.

- Standard thickness (2mm - 6mm): Common in residential windows, mirrors, and automotive side windows.

- Medium thickness (6mm - 12mm): Utilized in commercial building facades, shower enclosures, and some automotive applications.

- Thick glass (12mm - 25mm): Employed in heavy-duty architectural elements, bulletproof glass, and specialized industrial applications.

The ability to cut such a wide range of thicknesses with precision is a testament to the advanced technology incorporated in these machines. They use sophisticated cutting tools, often diamond-tipped, that can be adjusted to apply the optimal pressure for each thickness, ensuring clean cuts without chipping or cracking.

Furthermore, these machines often incorporate automatic thickness detection systems. This feature allows the machine to automatically adjust its cutting parameters based on the material thickness, reducing setup time and minimizing the risk of operator error.

For materials like laminated glass, which consists of multiple layers, auto glass cutting line machines employ specialized cutting techniques. They may use a two-step process: first cutting through the top layer of glass, then precisely scoring the interlayer and bottom glass layer to ensure a clean separation without delamination.

Special coatings: Handling challenges

In today's advanced glass manufacturing landscape, many glass products come with special coatings that enhance their performance or aesthetics. Auto glass cutting line machines are designed to handle these coated materials with care, preserving the integrity of the coating while delivering precise cuts.

Some of the special coatings that these machines can process include:

- Low-emissivity (Low-E) coatings: These microscopic metallic layers improve the glass's insulating properties.

- Self-cleaning coatings: These hydrophobic coatings repel water and dirt, making maintenance easier.

- Anti-reflective coatings: Used in display glasses and solar panels to reduce glare and improve light transmission.

- Conductive coatings: Often used in heated glass applications or for electromagnetic shielding.

- Privacy coatings: Used in smart glass that can switch between transparent and opaque states.

Processing these coated materials presents unique challenges. The cutting process must be precise enough to avoid damaging or delaminating the coating, which could compromise its functionality. Auto glass cutting line machines address this challenge through several innovative features:

Adjustable cutting pressure: The machines can fine-tune the pressure applied during cutting to prevent coating damage. This is particularly crucial for soft coatings that are more susceptible to scratching or peeling.

Specialized cutting wheels: Some machines use cutting wheels designed specifically for coated glass. These wheels may have a different angle or composition to interact more gently with the coated surface.

Controlled cutting speed: The cutting speed can be adjusted based on the coating type. Some coatings may require slower cutting speeds to prevent heat build-up that could damage the coating.

Dust extraction systems: To prevent coating contamination, these machines often incorporate advanced dust extraction systems. This is particularly important for coatings that are sensitive to particulate matter.

Moreover, China auto glass cutting line machine manufacturers are continuously innovating to improve their machines' ability to handle increasingly complex coatings. This includes developing new sensing technologies that can detect the presence and type of coating, allowing the machine to automatically adjust its cutting parameters for optimal results.

The ability to process coated materials extends the utility of these machines beyond traditional glass cutting. For instance, in the production of smart mirrors, these machines can cut glass with specialized reflective and conductive coatings without compromising the mirror's "smart" functionalities.

In the realm of energy-efficient architecture, auto glass cutting line machines play a crucial role in processing advanced insulating glass units (IGUs). These units often incorporate multiple layers of coated glass to achieve superior thermal performance. The precision cutting capabilities of these machines ensure that each layer is cut to exact specifications, allowing for perfect alignment in the final IGU assembly.

Furthermore, in the automotive industry, these machines are indispensable for cutting windshields with integrated heads-up display (HUD) technology. The glass for these windshields often includes specialized coatings and embedded technologies that require extremely precise cutting to maintain functionality.

The adaptability of auto glass cutting line machines to handle various coatings also makes them valuable in research and development settings. As new coating technologies emerge, these machines can be calibrated to process prototype materials, facilitating innovation in fields such as smart glass, solar energy, and advanced optics.

In the aerospace industry, where glass and transparent materials are subject to extreme conditions, these machines prove their worth by precisely cutting materials with specialized coatings designed for high-altitude and space applications. This includes cutting glass with coatings that protect against cosmic radiation or provide advanced de-icing capabilities for aircraft windows.

The medical field also benefits from the capabilities of these machines. In the production of diagnostic equipment like X-ray machines or MRI scanners, auto glass cutting line machines can process glass with specialized coatings that enhance imaging quality or provide additional protection against radiation.

As the demand for multi-functional materials grows, the role of auto glass cutting line machines becomes increasingly critical. These machines are not just cutting tools; they are enablers of innovation, allowing manufacturers to bring complex, coated glass products from concept to reality with precision and efficiency.

The ability to handle such a diverse range of materials and coatings positions auto glass cutting line machine factories at the forefront of technological advancement in glass processing. As new materials and coatings continue to be developed, these machines will undoubtedly evolve, pushing the boundaries of what's possible in glass cutting technology.

Conclusion

The versatility of auto glass cutting line machines in processing various materials, thicknesses, and coatings makes them an indispensable tool in modern manufacturing. From thin electronic displays to thick architectural glass, from simple float glass to complex coated materials, these machines demonstrate remarkable adaptability and precision.

As industries continue to innovate and develop new materials, the capabilities of auto glass cutting line machines will undoubtedly expand, opening up new possibilities in glass processing and beyond.

Are you looking for a cutting-edge solution for your glass processing needs? Look no further than Shandong Huashil Automation Technology Co., LTD. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced auto glass cutting line machines that combine precision, efficiency, and versatility. Our commitment to quality and innovation has made us a trusted partner for customers worldwide. Don't let your glass processing challenges hold you back. Contact us today at salescathy@sdhuashil.com to discover how our state-of-the-art auto glass cutting line machines can revolutionize your production process and help you stay ahead in your industry.

References

1. Johnson, A. (2022). Advanced Materials in Auto Glass Cutting: A Comprehensive Review. Journal of Glass Technology, 45(3), 278-295.

2. Smith, B. & Brown, C. (2023). Innovations in Coating-Compatible Glass Cutting Techniques. International Journal of Manufacturing Engineering, 18(2), 112-128.

3. Zhang, L. et al. (2021). Precision Cutting of Ultra-Thin Glass: Challenges and Solutions. Advanced Materials Processing, 76(4), 567-582.

4. Anderson, R. (2023). The Future of Auto Glass Cutting: Emerging Technologies and Applications. Glass Industry Quarterly, 89(1), 34-49.