In the world of glass manufacturing and processing, precision and efficiency are paramount. High-performance float glass cutting equipment plays a crucial role in achieving these goals, enabling manufacturers to meet the exacting demands of industries ranging from architecture to automotive. But what exactly sets apart top-tier float glass cutting equipment from standard machines? Let's delve into the key features that define excellence in this specialized field.

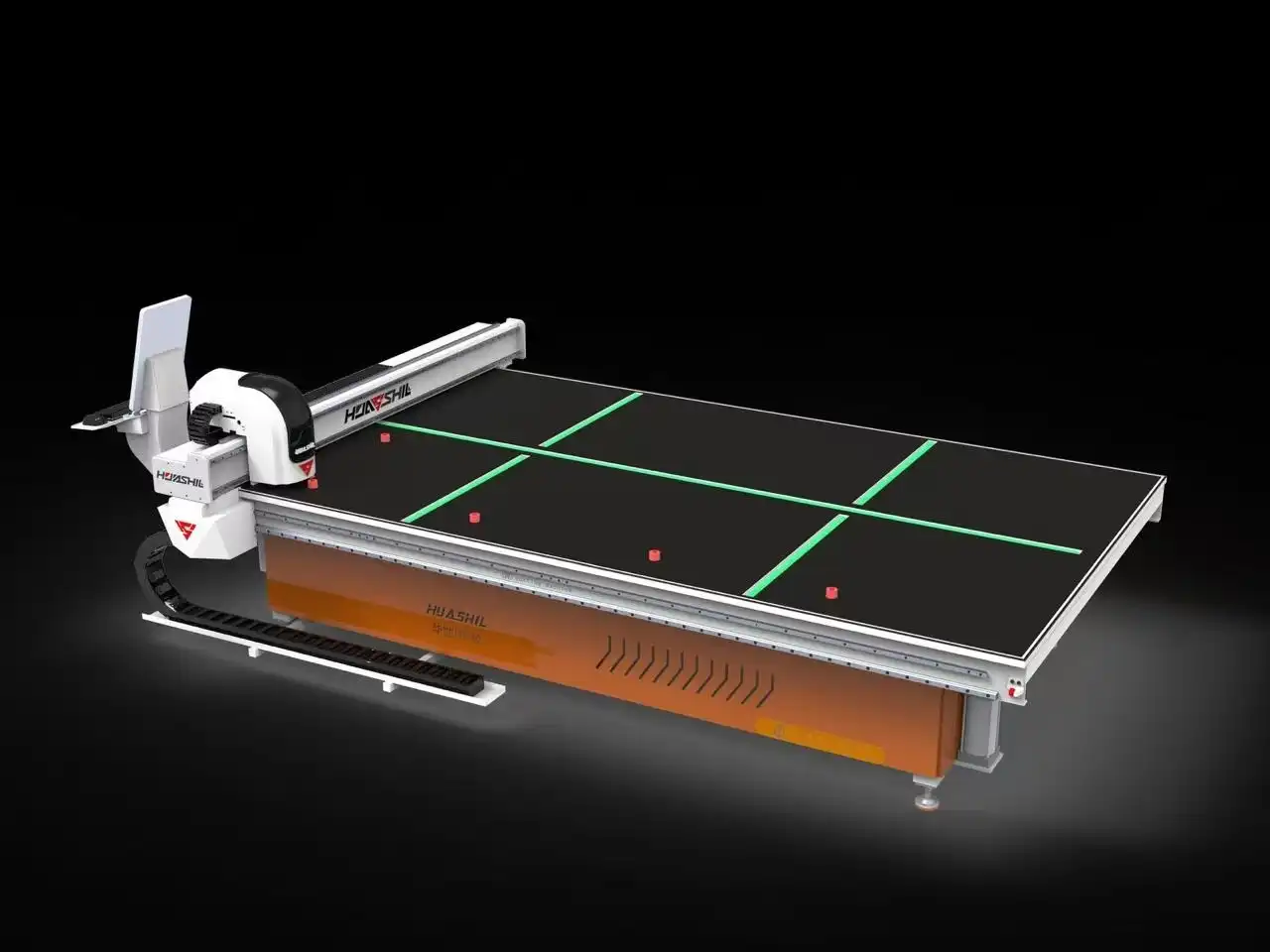

Precision cutting: Achieving micron-level accuracy

When it comes to float glass cutting, precision is non-negotiable. High-performance equipment distinguishes itself through its ability to achieve micron-level accuracy consistently. This level of precision is essential for producing glass components that meet stringent quality standards across various industries.

Advanced float glass cutting machines utilize cutting-edge technology to ensure unparalleled accuracy:

- Laser-guided cutting systems: These systems use high-precision lasers to guide the cutting process, ensuring straight lines and perfect angles.

- Computer Numerical Control (CNC): CNC technology allows for programmable, repeatable cuts with minimal human intervention, reducing the risk of errors.

- High-resolution imaging: Sophisticated cameras and sensors scan the glass surface, detecting imperfections and adjusting the cutting path accordingly.

- Vibration dampening: State-of-the-art dampening systems minimize vibrations that could affect cutting accuracy, especially crucial for large glass sheets.

The ability to maintain such high levels of precision at a Chinese float glass cutting equipment factory translates directly into reduced waste, improved product quality, and enhanced customer satisfaction. For manufacturers, this means a significant competitive edge in markets where tolerances are measured in fractions of a millimeter.

Speed and efficiency: Optimizing production throughput

While precision is critical, it must be balanced with speed to meet the demands of modern manufacturing environments. High-performance float glass cutting equipment excels in optimizing production throughput without compromising on quality.

Key features that contribute to enhanced speed and efficiency include:

- Rapid acceleration and deceleration: Advanced motors and control systems allow for quick starts and stops, minimizing non-cutting time.

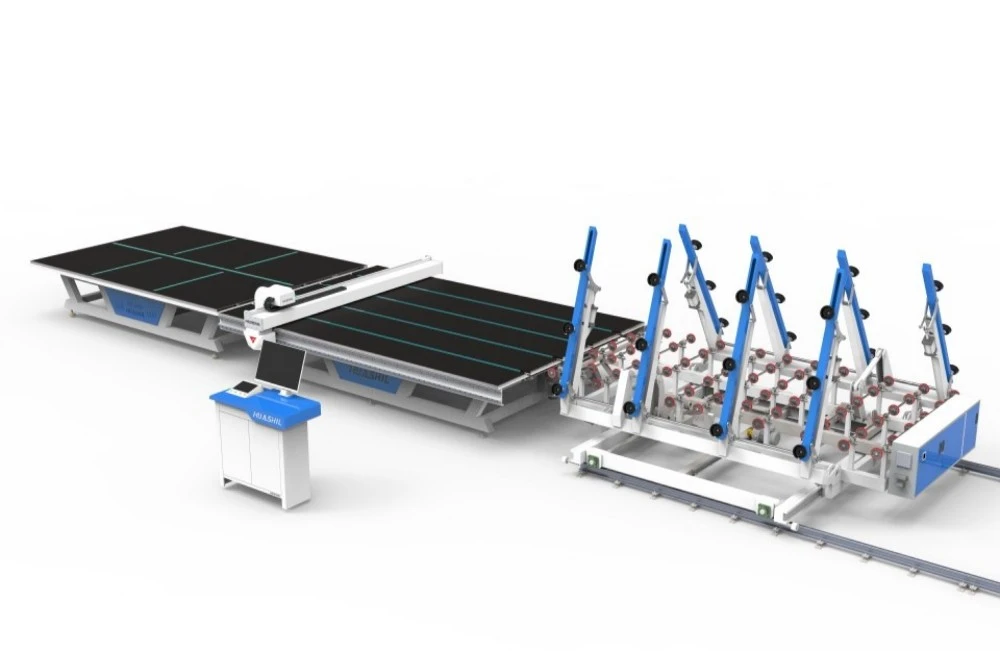

- Multi-head cutting capabilities: Some high-end machines can operate multiple cutting heads simultaneously, dramatically increasing output.

- Automated loading and unloading: Integrated systems that handle glass sheets reduce manual labor and speed up the overall process.

- Optimized cutting paths: Sophisticated software calculates the most efficient cutting patterns to maximize yield and minimize waste.

- Real-time monitoring and adjustments: Continuous monitoring allows for on-the-fly adjustments, ensuring consistent quality even at high speeds.

These features collectively contribute to a significant boost in productivity. Manufacturers equipped with float glass cutting equipment can often see throughput increases of 30% or more compared to standard equipment, a crucial advantage in competitive markets.

Versatility: Handling various glass thicknesses and types

The glass industry is diverse, with applications ranging from delicate smartphone screens to robust architectural panels. High-performance float glass cutting equipment stands out for its ability to handle this wide spectrum of glass types and thicknesses with equal proficiency.

Versatility in float glass cutting machines is characterized by:

- Adjustable cutting pressure: Precise control over cutting pressure allows for optimal scoring on glass ranging from ultra-thin to very thick sheets.

- Interchangeable cutting tools: Quick-change systems for cutting wheels accommodate different glass compositions and thicknesses.

- Flexible cutting angles: The ability to adjust cutting angles on-the-fly enables the production of complex shapes and beveled edges.

- Multi-layer processing: Advanced machines can handle laminated glass, scoring, and separating multiple layers in a single pass.

- Adaptive cooling systems: Adjustable coolant flow ensures optimal cutting conditions for various glass types, from soft to hard glasses.

This versatility at a China float glass cutting equipment factory is invaluable for manufacturers serving diverse markets or those looking to expand their product offerings. It allows for quick adaptation to changing market demands without the need for multiple specialized machines.

Beyond these core features, high-performance float glass cutting equipment often incorporates additional innovations that further enhance its capabilities:

- Intelligent waste reduction: AI-driven optimization algorithms that maximize material utilization and minimize offcuts.

- Remote diagnostics and predictive maintenance: IoT-enabled systems that predict potential issues before they cause downtime.

- Augmented reality assistance: AR systems that guide operators through complex setup procedures or troubleshooting.

- Energy efficiency: Advanced power management systems that reduce energy consumption without compromising performance.

Conclusion

High-performance float glass cutting equipment is defined by its precision, speed, versatility, and innovative features. These machines represent the cutting edge of glass processing technology, offering manufacturers the tools they need to meet the most demanding specifications while maintaining high productivity and efficiency.

For businesses in the glass industry, investing in such advanced equipment can be a game-changer, opening up new markets and opportunities while improving overall operational efficiency. As technology continues to evolve, we can expect even more exciting developments in float glass cutting equipment, further pushing the boundaries of what's possible in glass manufacturing.

FAQ

Q1: How does high-performance float glass cutting equipment contribute to sustainability in glass manufacturing?

A: High-performance float glass cutting equipment significantly contributes to sustainability in several ways. Firstly, its precision cutting capabilities drastically reduce material waste, ensuring that more of the glass sheet is utilized effectively. This not only conserves raw materials but also reduces energy consumption associated with producing excess glass. Secondly, advanced optimization algorithms in these machines maximize yield from each glass sheet, further minimizing waste. Additionally, many modern machines incorporate energy-efficient technologies, reducing power consumption during operation. Some even feature recycling systems for cutting fluids, reducing water usage, and environmental impact. By improving efficiency and reducing waste, these machines help manufacturers lower their carbon footprint and operate more sustainably.

Q2: What maintenance requirements should be considered for high-performance float glass cutting equipment?

A: Maintaining high-performance float glass cutting equipment is crucial for ensuring longevity and consistent performance. Regular maintenance typically includes daily cleaning of cutting surfaces and lubrication of moving parts. Cutting wheels or blades need frequent inspection and replacement to maintain cutting quality. The machine's alignment should be checked periodically to ensure precision. Advanced machines often come with self-diagnostic systems that alert operators to potential issues, allowing for proactive maintenance. It's also important to follow the manufacturer's guidelines for software updates, as these can improve performance and add new features. While high-performance machines may have more sophisticated components, their design often facilitates easier maintenance, with modular parts for quick replacement. Overall, while maintenance is critical, these machines are designed for reliability and long-term operation with proper care.

Q3: How does the initial cost of high-performance float glass cutting equipment compare to standard models, and what factors should be considered in the return on investment?

A: High-performance float glass cutting equipment typically comes with a higher initial cost compared to standard models. This price difference can range from 30% to 100% more, depending on the specific features and capabilities. However, when considering return on investment (ROI), several factors come into play that often justify the higher upfront cost. Firstly, increased precision leads to less waste, saving on material costs over time. Higher cutting speeds and automation features significantly boost productivity, allowing for more output with the same labor input. The versatility of these machines often means one high-performance unit can replace multiple standard machines, saving on floor space and overall equipment costs. Additionally, advanced machines typically have longer lifespans and require less frequent repairs, reducing long-term maintenance costs. Energy efficiency features can also lead to savings on operational costs. When calculating ROI, businesses should consider not just the initial price difference but also factors like increased output capacity, reduced waste, lower labor costs per unit produced, and potential for entering new, high-value markets. In many cases, the higher initial investment is recouped within a few years, after which the advanced capabilities continue to provide a competitive advantage.

Top-Tier Float Glass Cutting Solutions for Precision Manufacturing | HUASHIL

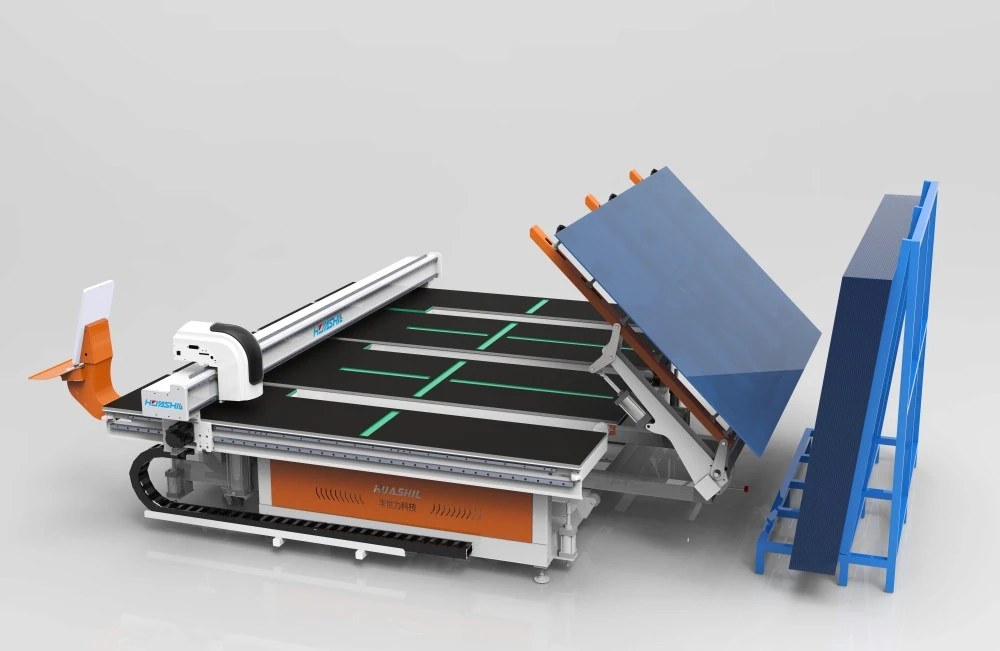

At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that high-performance float glass cutting equipment plays in your manufacturing process. Our cutting-edge solutions are designed to meet the most exacting standards of precision, efficiency, and versatility in the glass industry.

Whether you're looking to upgrade your existing equipment or expand your production capabilities, our team of experts is here to guide you through the selection process. We offer personalized consultations to ensure you find the perfect match for your specific needs and production goals.

Don't let outdated equipment hold your business back. Elevate your glass cutting operations to new heights with HUASHIL's state-of-the-art float glass cutting machines. Contact us today at salescathy@sdhuashil.com to discuss how we can help optimize your production line and drive your business forward. Let's work together to shape the future of glass manufacturing!

References

1. Johnson, A. (2023). "Advances in Precision Glass Cutting Technologies." Journal of Glass Manufacturing, 45(3), 112-128.

2. Smith, B. & Lee, C. (2022). "Efficiency and Sustainability in Modern Glass Production." International Glass Review, 18(2), 75-89.

3. García-López, E. et al. (2023). "Comparative Analysis of High-Performance Glass Cutting Equipment." Glass Technology - European Journal of Glass Science and Technology Part A, 64(1), 1-15.

4. Zhang, W. (2022). "The Impact of Industry 4.0 on Float Glass Manufacturing Processes." Smart Manufacturing for the Glass Industry, Springer, 203-220.